Multifunctional integrated meat cutter

A meat cutter, multi-functional technology, applied in metal processing and other directions, can solve problems such as strong taste, incomplete cutting, waste and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

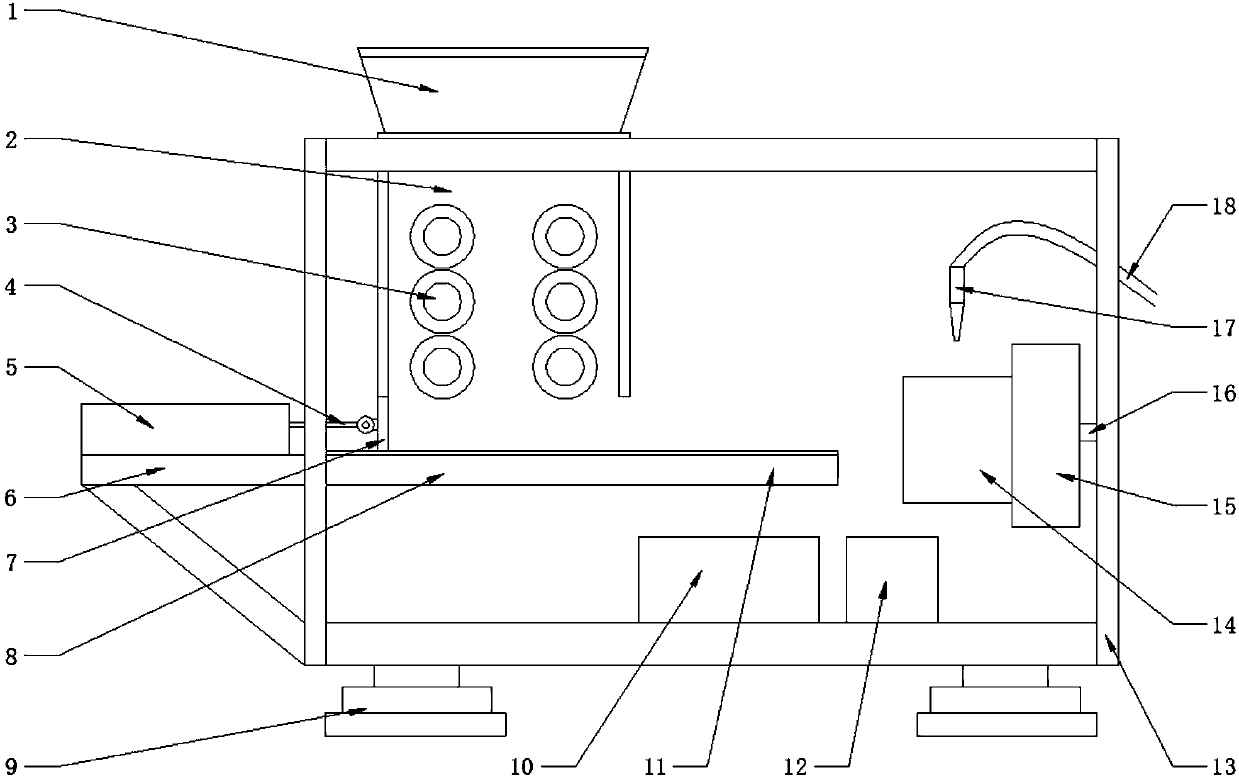

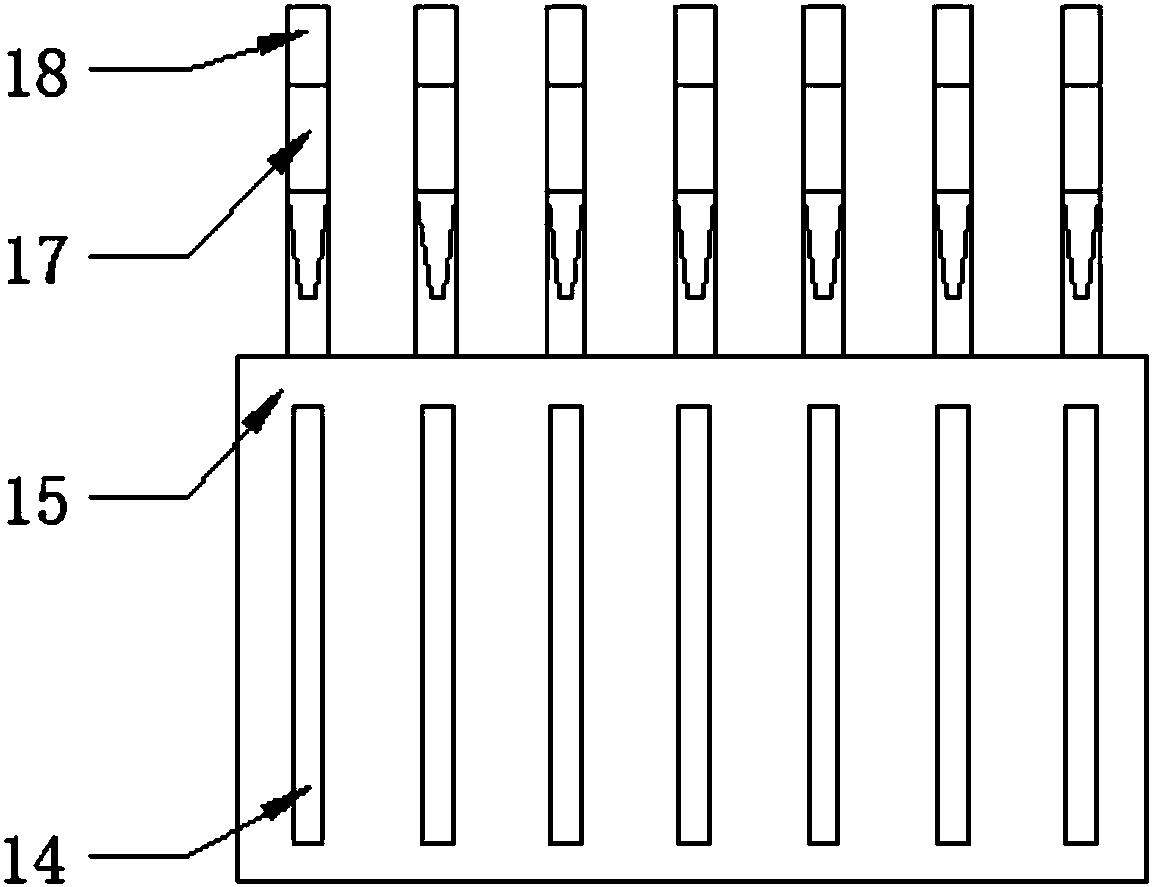

[0022] This embodiment combines figure 1 , figure 2 with image 3 As shown, a multi-functional integrated meat cutting machine includes a frame 13 of cuboid structure, the top side of the frame 13 is provided with a feed port 1, and the inner side of the feed port 1 is provided with a feed pipe 2 , the inner side of the feed pipe 2 is symmetrically provided with three pressure rollers 3, and the bottom of the feed pipe 2 is provided with a placement plate 8, and one end of the placement plate 8 stretches out from the frame 13 and forms a machine frame 6, the machine frame 6 is provided with a telescopic cylinder 5, the opening of the telescopic cylinder 5 faces the placement plate 8, and the telescopic cylinder 5 stretches out the connecting rod 4 through the opening, and the connecting rod 4 is connected with a meat pushing plate 7;

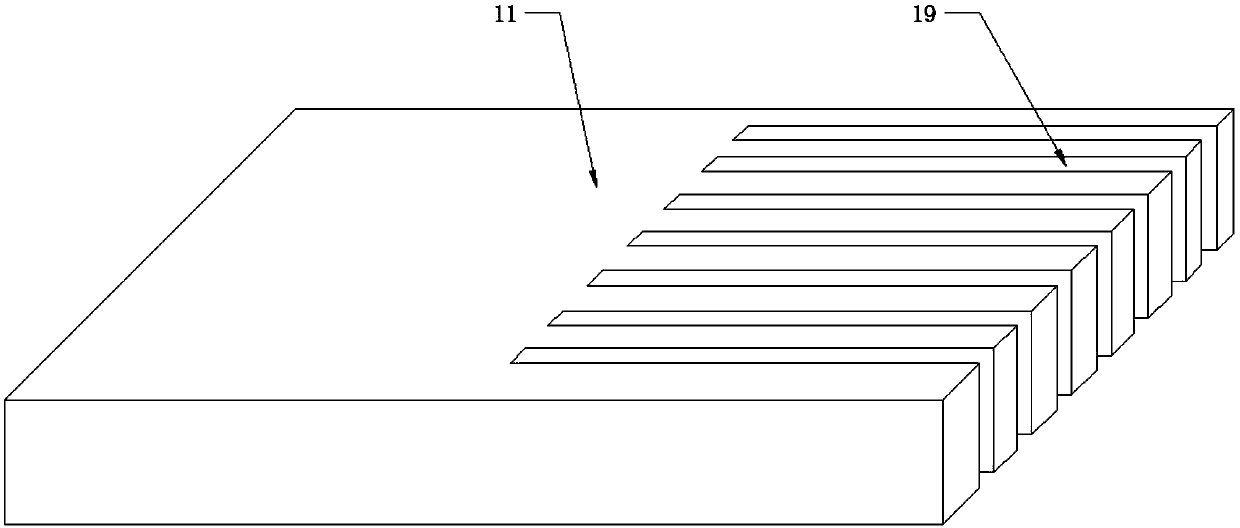

[0023] The other end of the placement plate 8 is extended to form an extension plate 11, and the end surface of the extension plate 11 is pr...

Embodiment 2

[0029] This embodiment is further improved based on embodiment 1, as figure 1 As shown, the top surfaces of the placement board 8 and the extension board 11 are both provided with chopping board surfaces.

[0030] During use, the extension plate 11 and the placement plate 8 will not be polluted by meat through the surface of the chopping board, and can be used for a long time.

Embodiment 3

[0032] This embodiment is further improved based on any one of Embodiments 1-2, such as figure 1 As shown, four legs 9 are welded at the bottom corners of the frame 13 .

[0033] During use, the meat slicer can cut meat stably through the four legs 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com