Slurry mixing device based on subway shield construction

A subway shield and slurry technology, applied in mining equipment, mixing plants, underground chambers, etc., can solve the problems of increasing labor costs, affecting construction progress, and inconvenient cleaning, so as to save labor costs, improve construction efficiency, Avoid the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

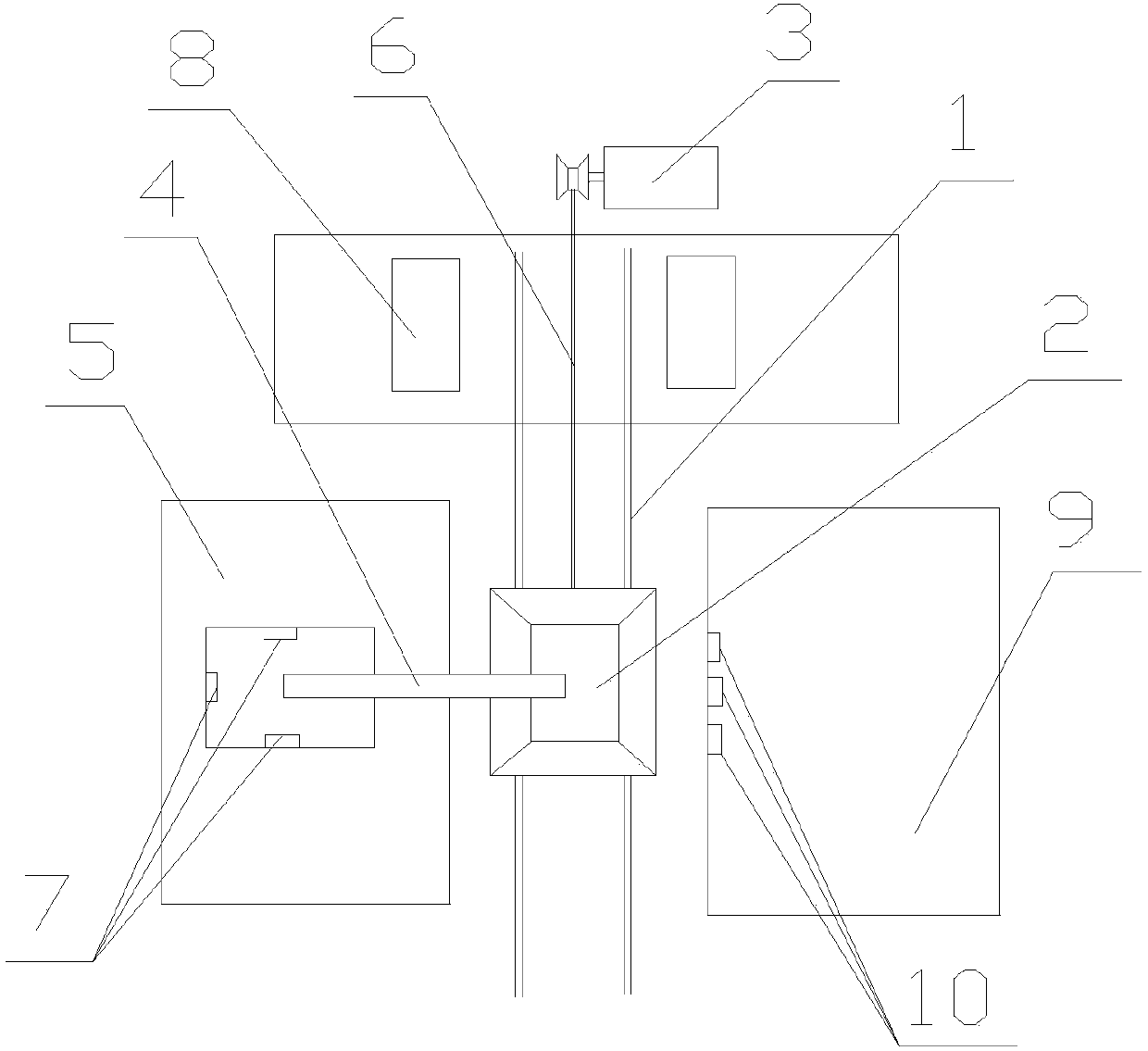

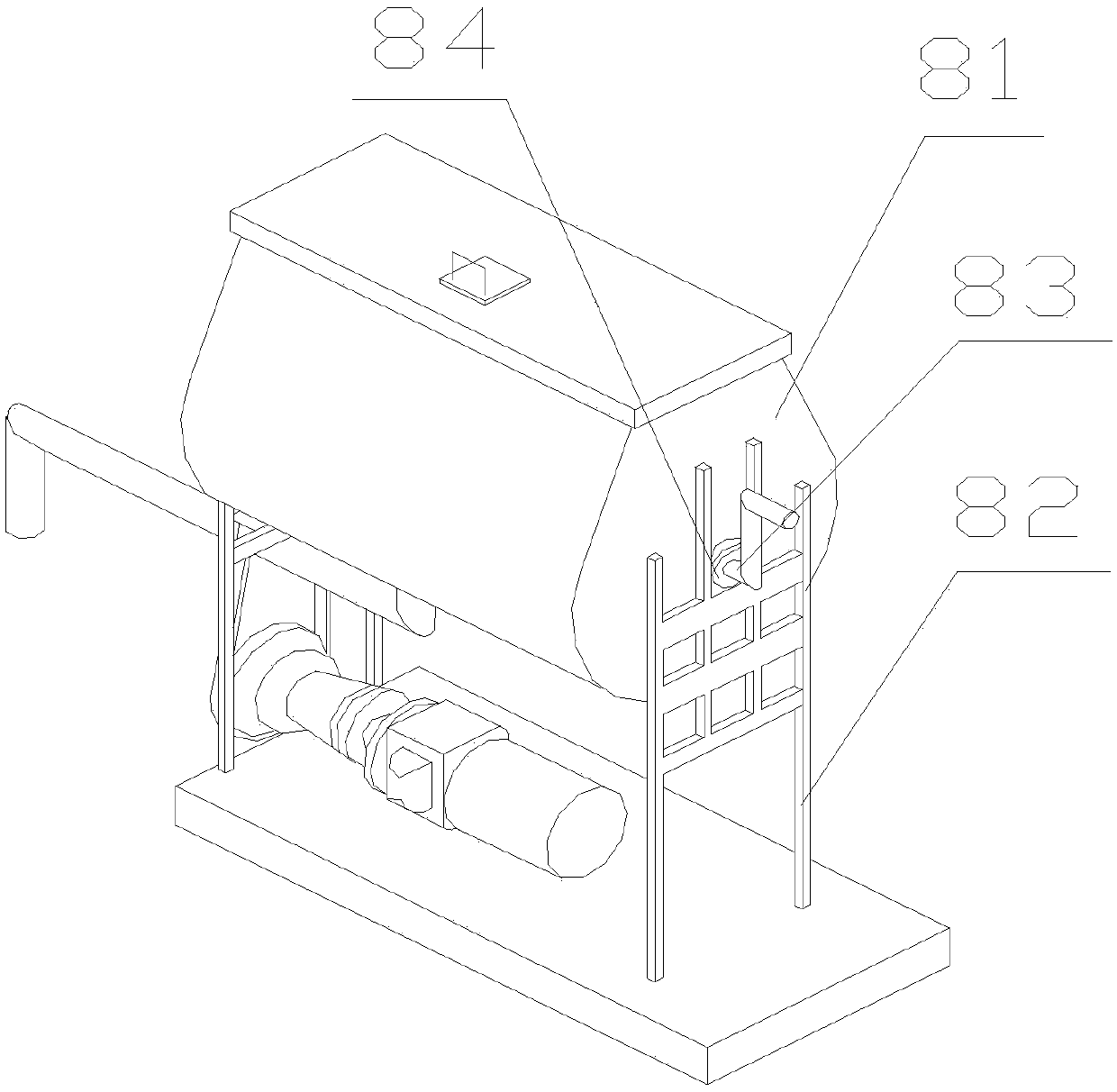

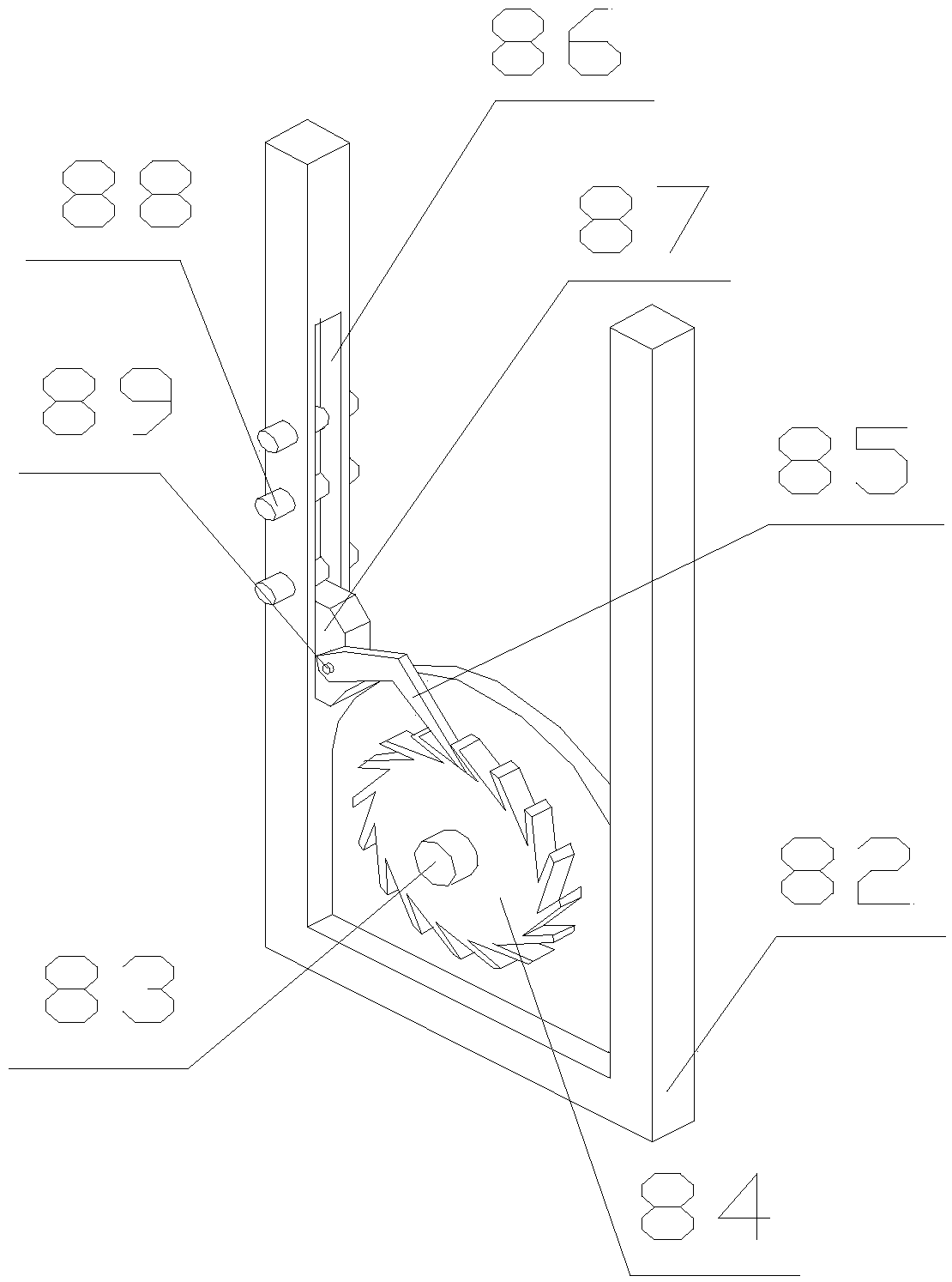

[0015] Such as Figure 1-3 As shown, the slurry mixing equipment based on the subway shield construction includes a track 1, a bucket car 2, a hoist 3, a screw conveyor 4, a sand field 5, a material warehouse 9, and a horizontal mixer 8, and the track 1 is longitudinally arranged , the bucket truck 2 is located on the track 1, the hoist 3 is installed on the top of the track 1 and is connected with the bucket truck 2 through a traction wire rope 6, and is used for pulling the bucket truck 2 to move. The screw conveyor 4 and the sand field 5 They are all located on the same side of the track 1. The sand field 5 is provided with more than one sand and gravel outlet 7, and the two ends of the screw conveyor 4 are respectively provided with a material inlet port and a material outlet port. The stone discharge port 7 is connected, the discharge port extends to the track 1 and is located above the bucket car 2, the material warehouse 9 is located on the other side of the track 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com