Mixing system of injected pulp in metro shield construction

A technology in subway shield tunneling and construction, applied in underground chambers, cement mixing devices, chemical instruments and methods, etc., can solve the problems of increased labor costs, time-consuming and laborious, inconvenient cleaning, etc., and achieve labor cost savings and convenient use , the effect of convenient washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

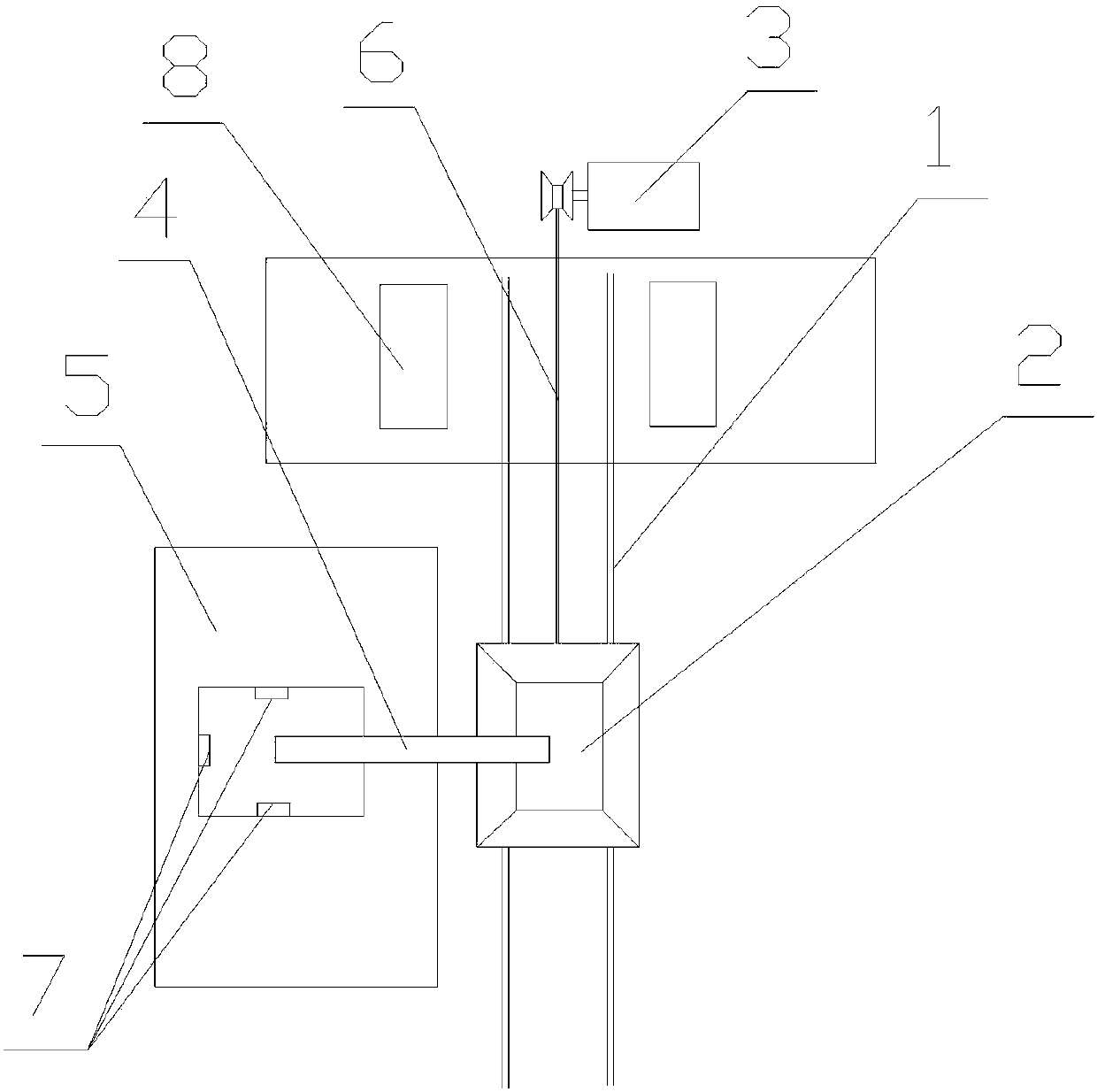

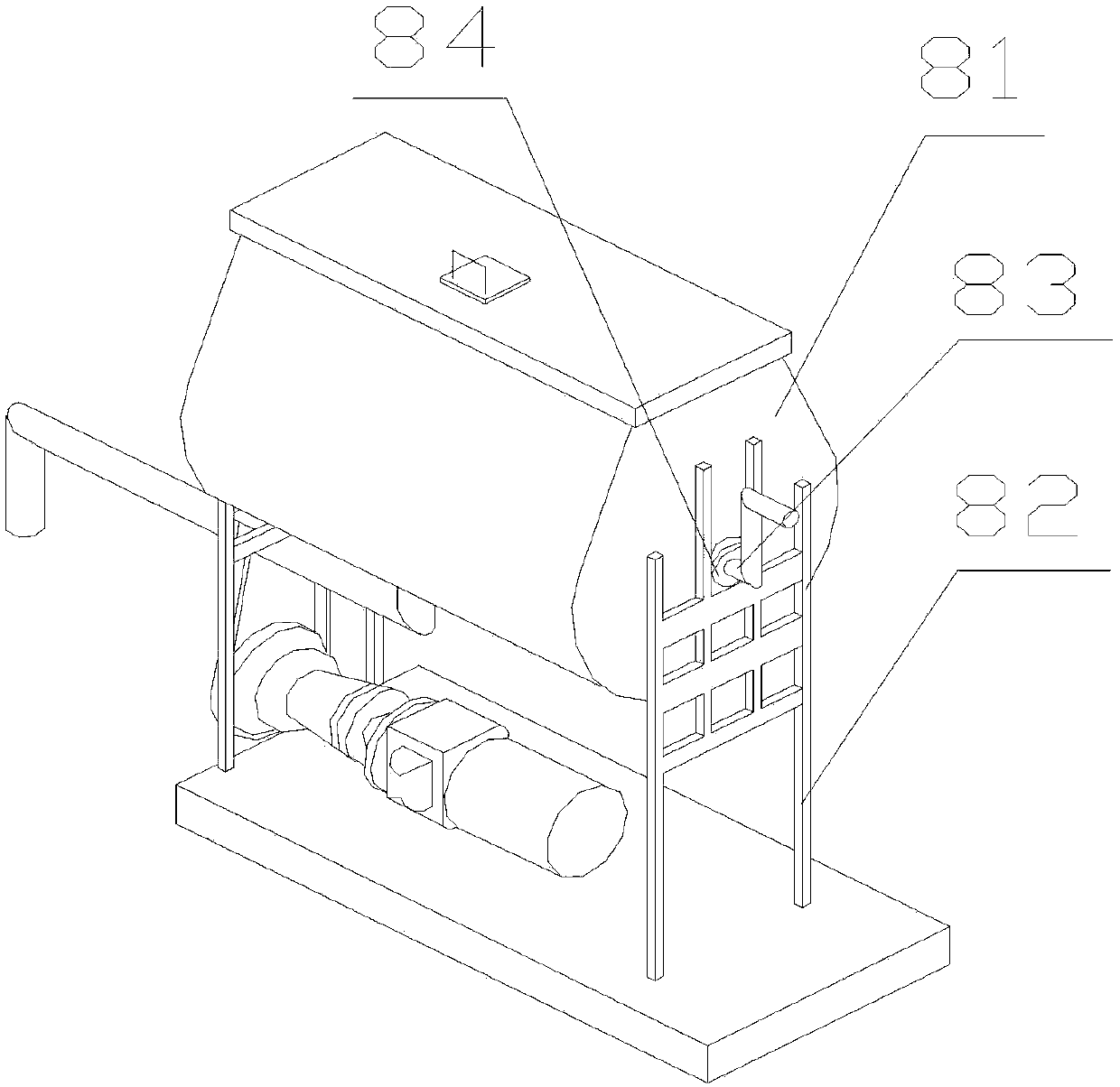

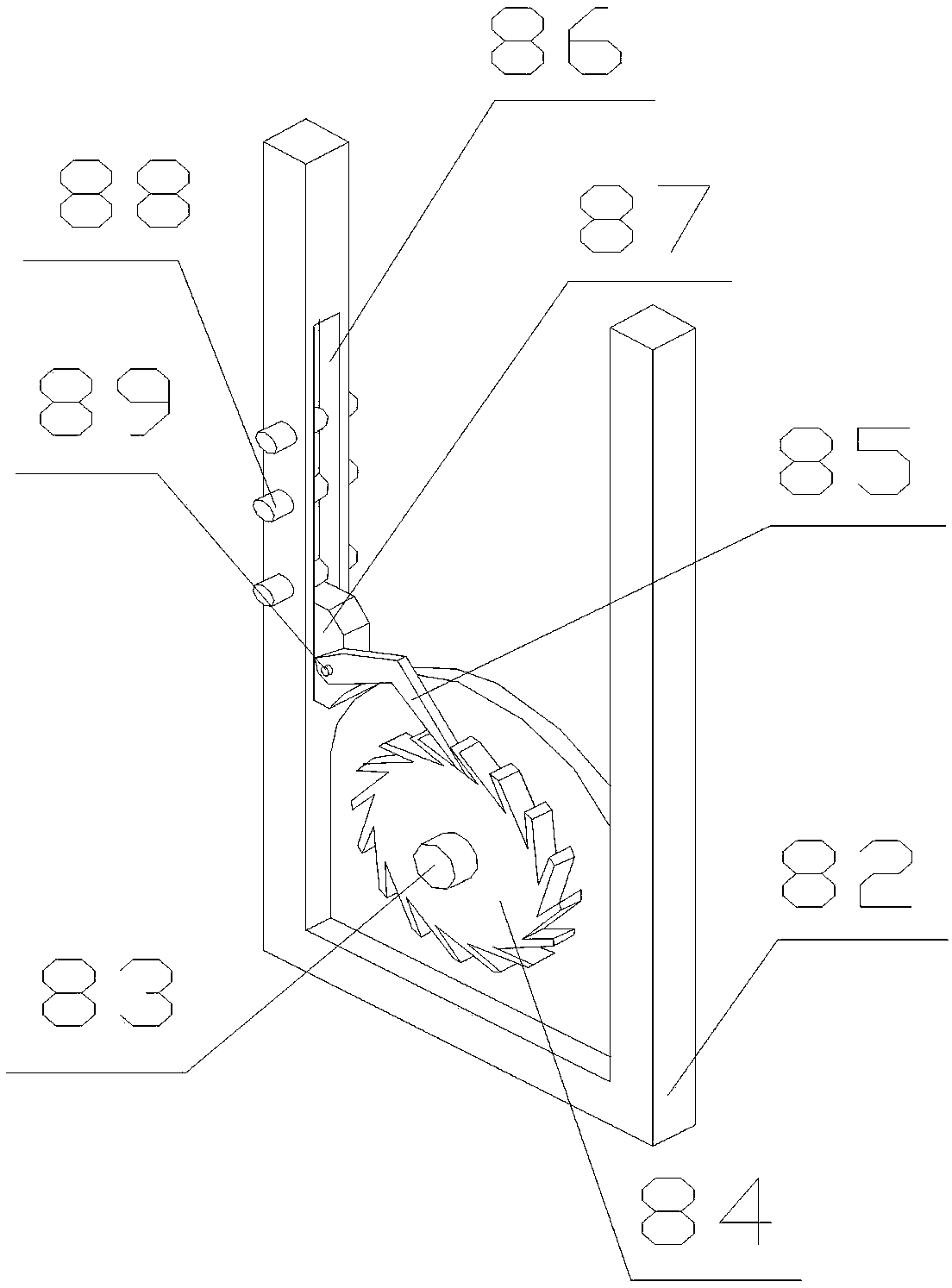

[0016] Such as Figure 1-3 As shown, a mixing system for medium-pressure grouting in subway shield construction includes a track 1, a bucket car 2, a hoist 3, a screw conveyor 4, a sand field 5, and a horizontal mixer 8, and the track 1 is vertically arranged , the bucket truck 2 is located on the track 1, the hoist 3 is installed on the top of the track 1 and is connected with the bucket truck 2 through a traction wire rope 6, and is used for pulling the bucket truck 2 to move. The screw conveyor 4 and the sand field 5 They are all located on the same side of the track 1. The sand field 5 is provided with more than one sand and gravel outlet 7, and the two ends of the screw conveyor 4 are respectively provided with a material inlet port and a material outlet port. The stone discharge port 7 is connected, and the discharge port extends to the track 1 and is located above the bucket car 2; the horizontal mixer 8 mainly includes a material cylinder 81 and a frame 82, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com