Automatic power generating hub based on piezoelectric materials

A piezoelectric material, automatic power generation technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, wheels, etc. Consume the driving kinetic energy of the vehicle and other problems to achieve the effect of improving the endurance, simple structure and increasing driving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment is applied when the vehicle is running.

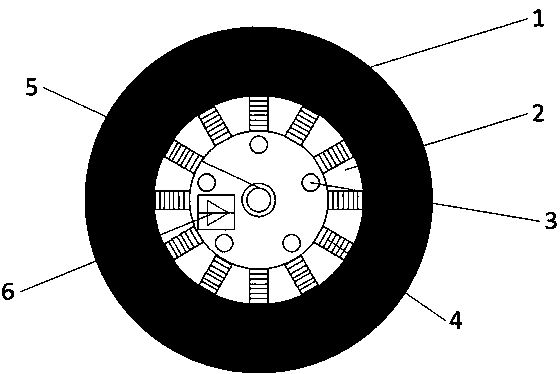

[0030] Such as figure 1 Shown, a self-generating hub based on piezoelectric materials. It is characterized in that it includes a vehicle hub structure 2 (including a flange mounting hole 3 ), a piezoelectric material assembly module 4 , an electric energy transmission slip ring 5 , and an energy recovery conversion circuit 6 .

[0031] When the vehicle is running, the wheels rotate, and the tire 1 bears the weight of the vehicle through the reaction force in contact with the ground to achieve balance.

[0032] The reaction force received by the tire 1 from the ground is transmitted to the piezoelectric material assembly module 4 through the hub 2, then to the flange of the hub, and finally to the shock absorbing bridge of the vehicle to support the vehicle body.

[0033] When the vehicle is running, the wheels transmit the force to each piezoelectric material module 4. During the rotation of the wheel, the posi...

Embodiment 2

[0037] This embodiment is applied when the vehicle is running.

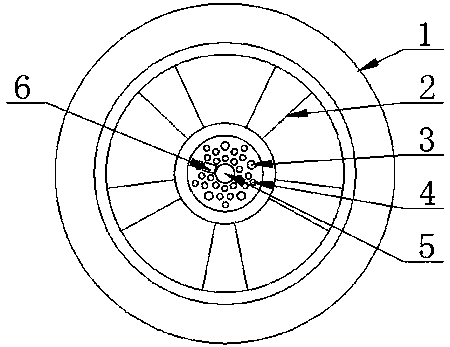

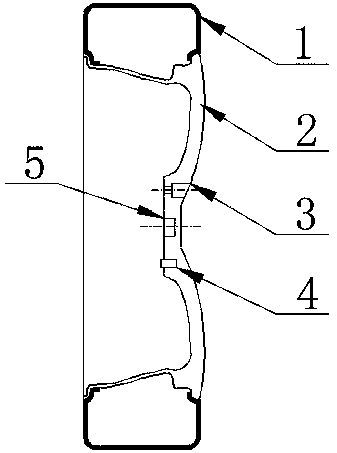

[0038] Such as figure 2 , image 3 Shown, a self-generating hub based on piezoelectric materials. It is characterized in that it includes a vehicle hub structure 2 (including a flange plate and a mounting hole 3 ), a piezoelectric material assembly module 4 , an energy recovery conversion circuit 6 , and an electric energy transmission slip ring 5 .

[0039] When the vehicle is running, the wheels rotate, and the tire 1 bears the weight of the vehicle through the reaction force in contact with the ground to achieve balance.

[0040] The reaction force received by the tire 1 from the ground is transmitted to the hub flange through the hub 2, then to the piezoelectric material assembly module 4, and finally to the vehicle shock absorber bridge to support the vehicle body.

[0041] When the vehicle is running, the wheels transmit the force to each piezoelectric material module 4. During the rotation of the wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com