Internal climbing tower crane climbing method without using inverted beam method

A technology for internal climbing towers and tower cranes, applied to cranes and other directions, can solve problems such as large safety hazards, large safety hazards, and low efficiency, and achieve the effects of reducing jacking investment, reducing high-altitude operations, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

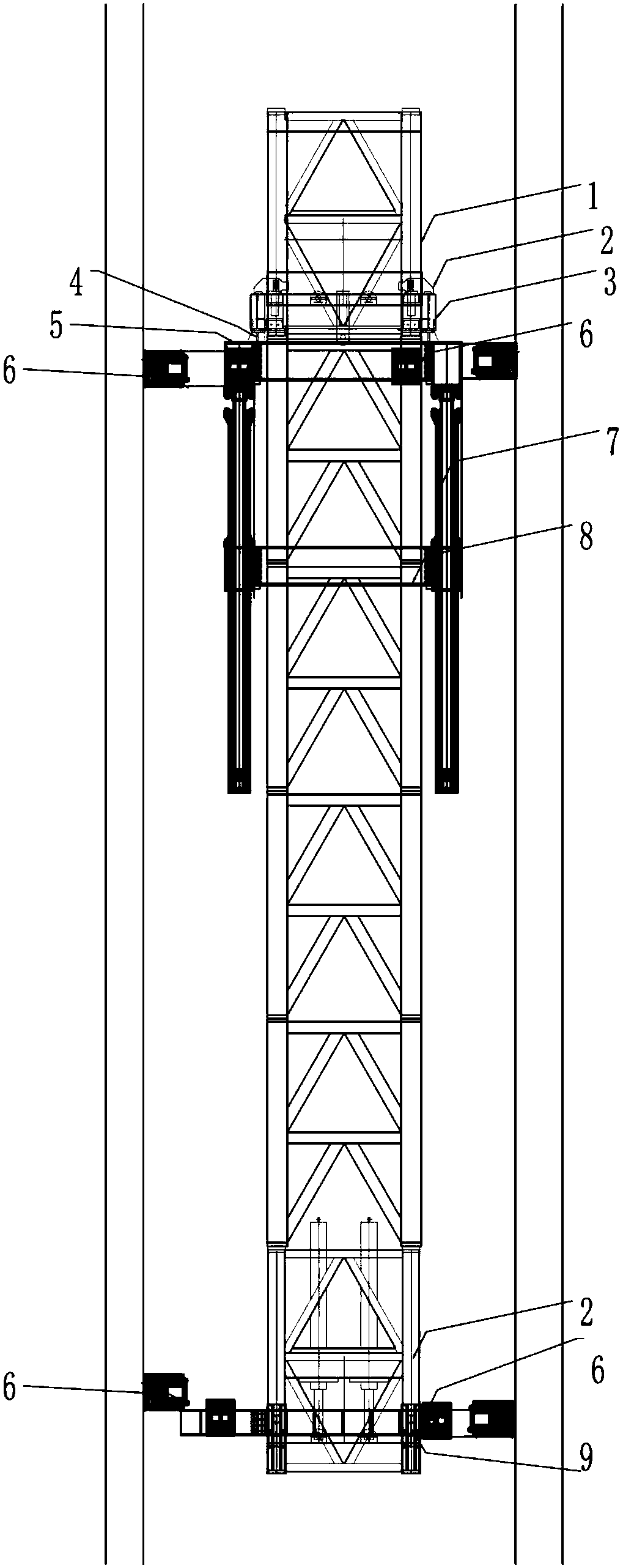

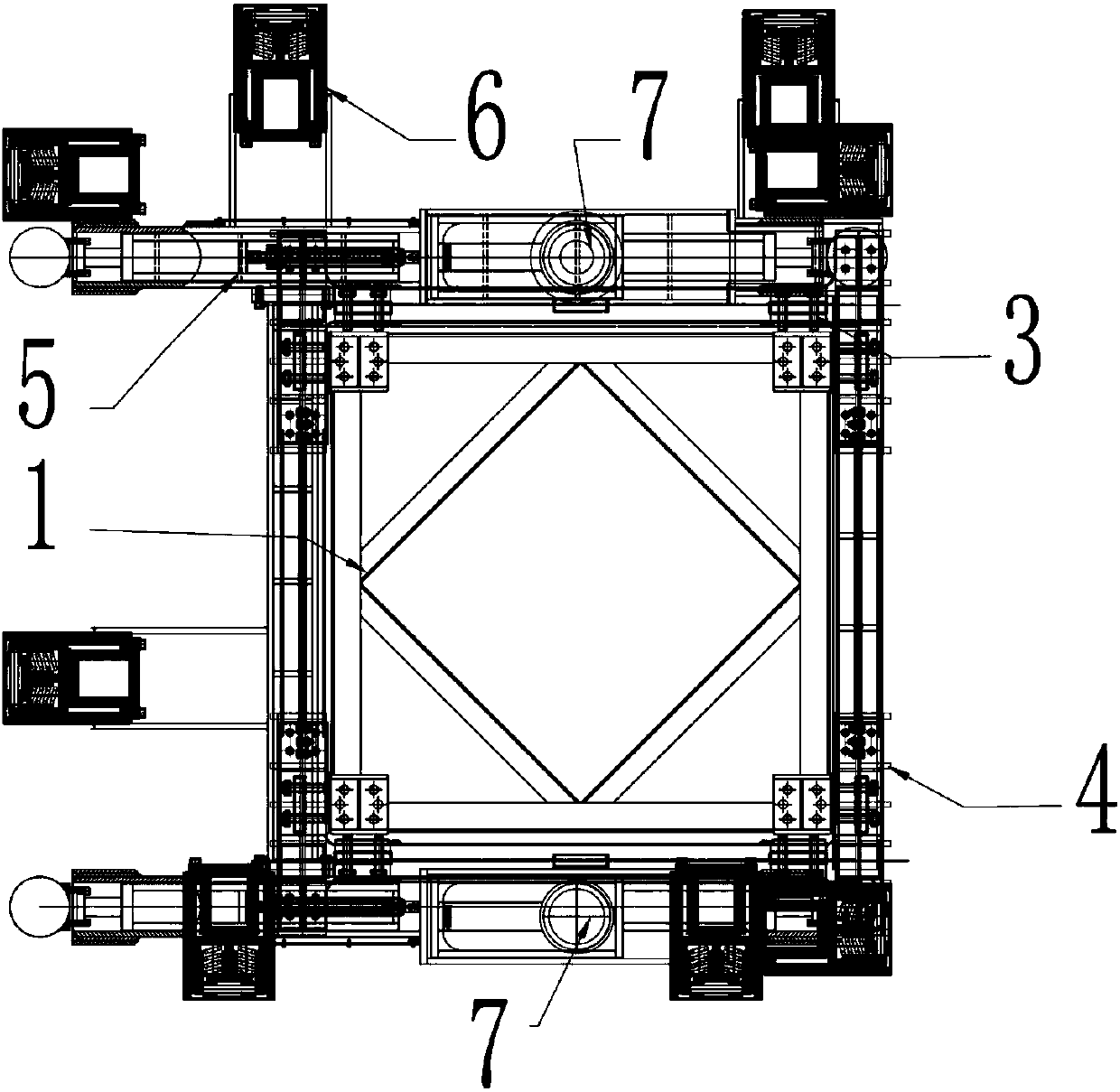

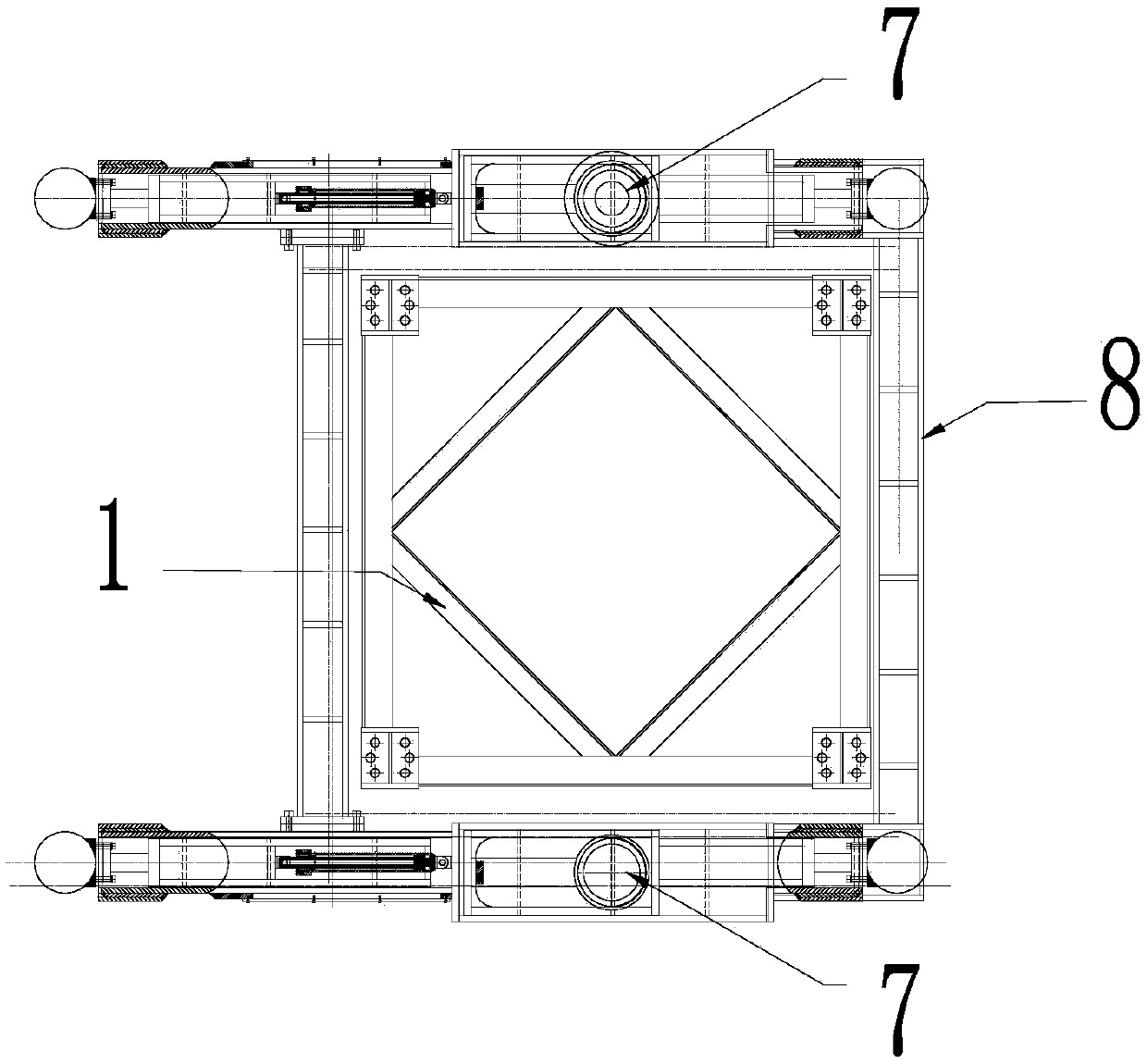

[0025] Such as Figure 1 to Figure 10 As shown, in an embodiment of the climbing method of an internal climbing tower crane without falling down in the present invention, it includes a tower crane 1, a climbing joint 2, a climbing frame 3, a stirrup 4, a tower crane upper beam 5, a limit guide device 6, a jacking Oil cylinder 7, tower crane middle beam 8, tower crane lower beam 9 and hydraulic control system.

[0026] Such as Figure 2 to Figure 4 As shown, the upper beam 5 of the tower crane, the middle beam 8 of the tower crane, and the lower beam 9 of the tower crane are all well-shaped beams, and the ends of the beams are supported on the main structure. The upper beam 5 of the tower crane, the middle beam 8 of the tower crane and the lower beam 9 of the tower crane are all located on the periphery of the tower crane 1, and are arranged sequentially from top to bottom along the height direction of the tower crane 1. The upper beam 5 of the tower crane is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com