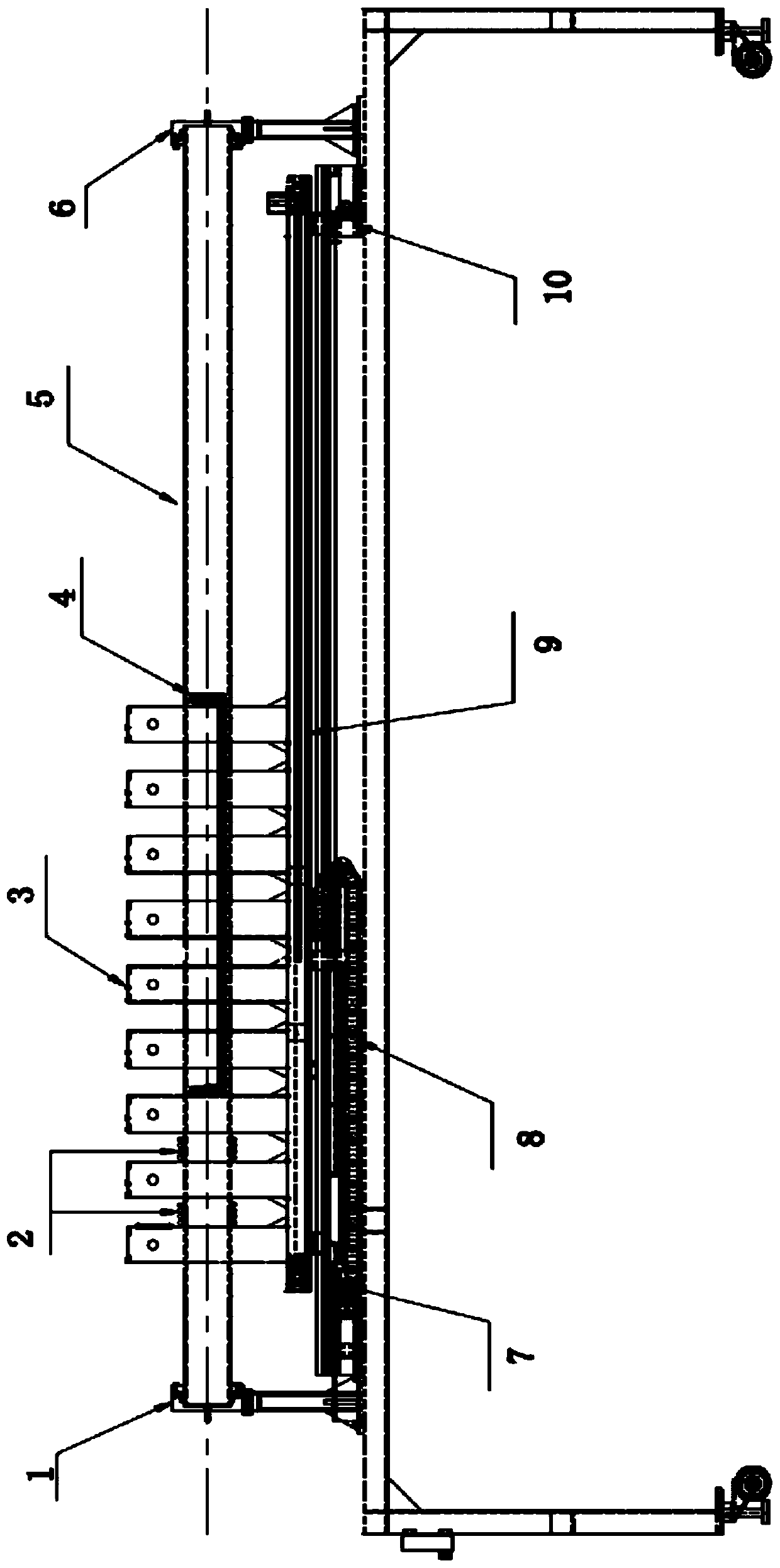

A high-purity indium purification device and method

A high-purity, horizontal technology, applied in the direction of improving process efficiency, can solve the problems of high cost, low production capacity, poor controllability, etc., and achieve the effect of easy control, high production capacity and short purification cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) Put the high-purity graphite boat containing 5N indium raw material into the quartz tube, and its front end (left end) is flush with the right end of the third resistance heater. The temperature of the first resistance heater, the second resistance heater and the third resistance heater is set to 150°C, the temperature of the cooling circulating water is 30°C to 40°C, the temperature of the other resistance heaters is set to 250°C, and the high-purity graphite boat After melting the 5N indium raw material, keep the temperature for 2 hours, open the guide rail, move the guide rail at a speed of 10mm / h, and perform directional solidification once to the rear end (right end) of the high-purity graphite boat to obtain the indium to be smelted;

[0062] (2) Set the temperature of the fourth resistance heater, the fifth resistance heater, the sixth resistance heater, the seventh resistance heater, the eighth resistance heater and the ninth resistance heater to 150°C, and w...

Embodiment 2

[0064] (1) Put the high-purity graphite boat containing 5N indium raw material into the quartz tube, and its front end (left end) is flush with the right end of the third resistance heater. The temperature of the first resistance heater, the second resistance heater and the third resistance heater is set to 150°C, the temperature of the cooling circulating water is 30°C to 40°C, the temperature of the other resistance heaters is set to 250°C, and the high-purity graphite boat After melting the 5N indium raw material, keep the temperature for 2 hours, open the guide rail, move the guide rail at a speed of 10mm / h, and perform directional solidification once to the rear end (right end) of the high-purity graphite boat to obtain the indium to be smelted;

[0065] (2) Set the temperature of the fourth resistance heater, the fifth resistance heater, the sixth resistance heater, the seventh resistance heater, the eighth resistance heater and the ninth resistance heater to 150°C, and w...

Embodiment 3

[0067] (1) Put the high-purity graphite boat containing 5N indium raw material into the quartz tube, and its front end (left end) is flush with the right end of the third resistance heater. After the air in the quartz tube is exhausted, high-purity hydrogen is introduced, and the first The temperature of the first resistance heater, the second resistance heater and the third resistance heater is set to 150°C, the temperature of the cooling circulating water is 30°C to 40°C, and the temperature of the other resistance heaters is set to 250°C. After the 5N indium raw material is melted, keep the temperature for 2 hours, open the guide rail, move the guide rail at a speed of 10mm / h, and perform directional solidification once to the rear end (right end) of the high-purity graphite boat to obtain the indium to be smelted;

[0068] (2) Set the temperature of the fourth resistance heater, the fifth resistance heater, the sixth resistance heater, the seventh resistance heater, the eig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com