Method for preparing high-purity indium through multi-channel array type directional solidification based on machine learning

A directional solidification and machine learning technology, applied in machine learning, instruments, manufacturing tools, etc., can solve problems such as the interaction of parameter complexity and difference in results, and achieve uniform heating temperature gradient distribution, stable temperature field, and strong controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

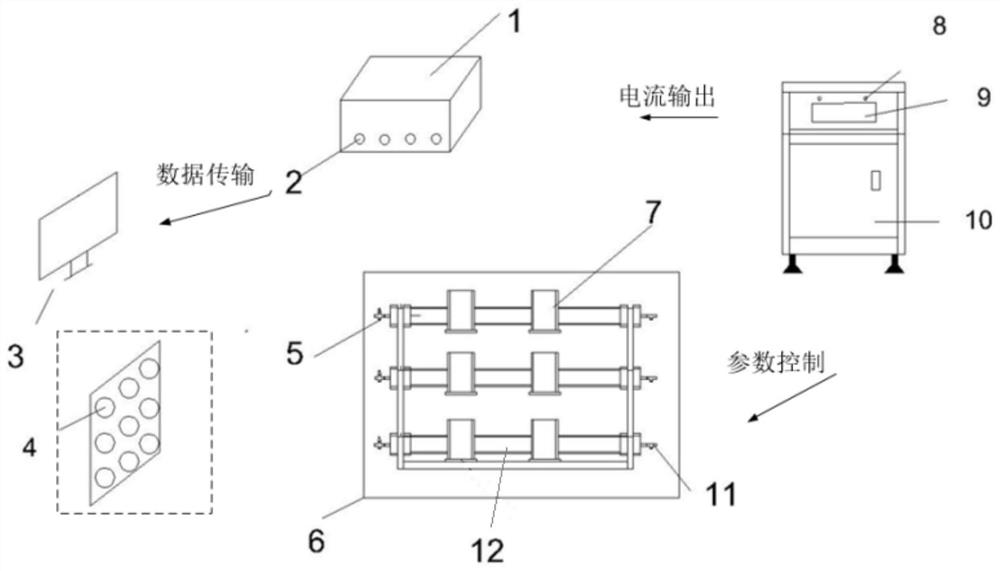

[0024] A method for preparing high-purity indium by multi-channel array directional solidification based on machine learning, the method steps are as follows:

[0025] S1. Purify indium under different directional solidification speed conditions first, the process is as follows:

[0026] S1.1 obtains 5N indium by the electrolysis method of the prior art, evenly packs it into 9 quartz boats, puts it into the quartz tube 12 of the three-by-three-array type multi-channel directional solidification furnace 6, closes the quartz tube, and starts the electrical control device. Open the control cabinet button 8 of the electrical control device, set the process parameters such as zone melting speed, zone melting times, gas flow, etc. on the panel 9, and open the vacuum system and protective gas system 5 of the three-by-three-array multi-channel directional solidification furnace. The air release valve 11 is evacuated, and the protective gas nitrogen is introduced, and the gas flow is ...

Embodiment 2

[0033] A method for preparing high-purity indium by multi-channel array directional solidification based on machine learning, and the purification of indium under the conditions of different directional solidification times is as follows:

[0034] (1) Put the 5N indium obtained by electrolysis into 9 quartz boats, put it into the quartz tube in the three-by-three-array multi-channel directional solidification furnace, close the quartz tube, start the electrical control device, evacuate, and pass the Protective gas hydrogen, the gas flow rate is 0.5L / min;

[0035] (2) The widths of the three-by-three-array-type multi-channel heaters of the three-by-three-array-type multi-channel directional solidification furnace are set to 20mm and 30mm, respectively, and they move directionally at the speed of 20mm / h and 30mm / h respectively, and the directional solidification is 1 ~6 times, the melting zone temperature is 180-200℃;

[0036] (3) Stop the furnace after the operation is complet...

Embodiment 3

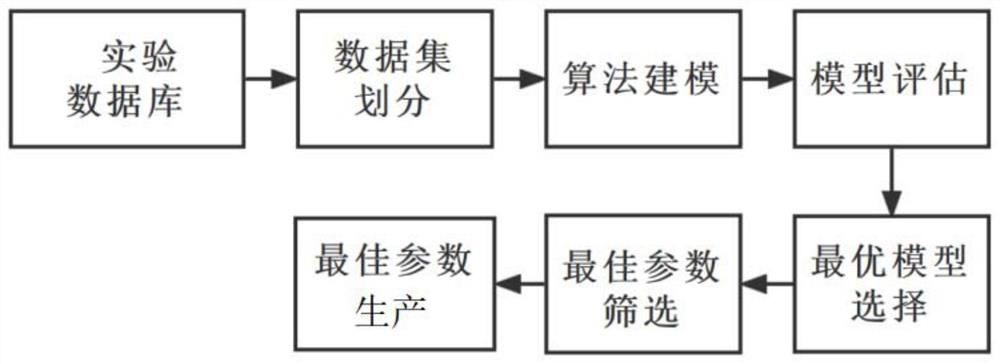

[0038] Based on the high-purity indium prepared in the above embodiment 2, machine learning is used to optimize the preparation of high-purity indium, and machine learning prediction of the high-purity indium database is performed, and the method is as follows:

[0039] S2. Construct a high-purity indium directional solidification data set: collect and record the moving speed of the directional solidification furnace, heater width, solidification times, melting zone temperature and the purity of product indium under the corresponding parameters obtained in the above step S1, and construct a table. The high-purity indium directional solidification dataset shown in 1 is used for subsequent data mining;

[0040] S3. Build a high-purity indium directional solidification process machine learning model: based on the process parameters of the above-mentioned embodiments, including heater moving speed, heater width, solidification times, melting zone temperature, gas flow rate, etc., a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com