Straight-barrel-shaped tungsten crucible

A tungsten crucible and straight cylinder technology, applied in the field of crucibles, can solve problems such as different thermal stress, uneven temperature distribution, large local deformation, etc., achieve uniform temperature distribution, shorten preparation time, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

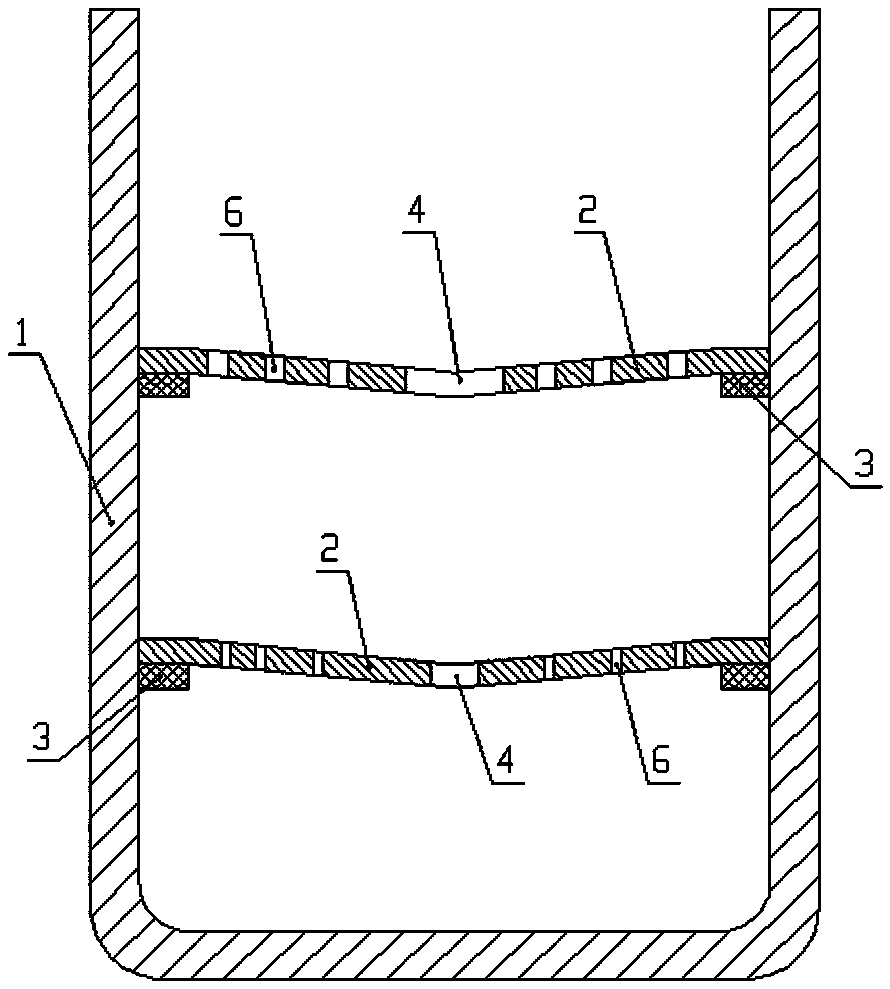

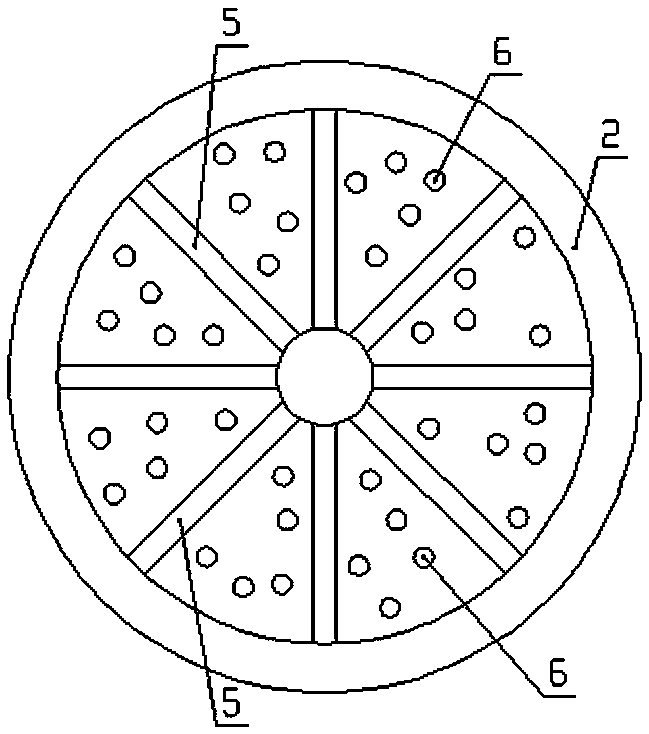

[0017] Such as Figure 1-2 As shown, the straight cylindrical tungsten crucible of the present invention comprises a crucible body 1 with a cylindrical structure and a loading plate 2 horizontally arranged in the crucible body 1, the loading plate 2 is a disc-shaped structure, and the upper part of the crucible body 1 is open. There are edge platforms 3 that protrude horizontally from the inner wall of the crucible body 1 under the edges on both sides of the loading plate 2, and the edges on both sides of the loading plate 2 are placed on the edge platforms 3, and a blanking hole 4 is opened in the center of the loading plate 2. The surface of the carrier plate 2 is spaced apart with drainage grooves 5, the drainage grooves 5 are arranged radially along the carrier plate 2, and the through holes 6 vertically penetrating through the carrier plate 2 are spaced between two adjacent drainage grooves 5.

[0018] There are at least two loading plates 2 inside the crucible body 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com