Bowl-shaped tungsten crucible

A tungsten crucible and bowl-shaped technology, applied in the field of bowl-shaped tungsten crucibles, can solve the problems of reducing the service life of tungsten crucibles, uneven temperature distribution, unusable tungsten crucibles, etc., and achieves the effects of accelerating melting speed, facilitating processing, and working stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

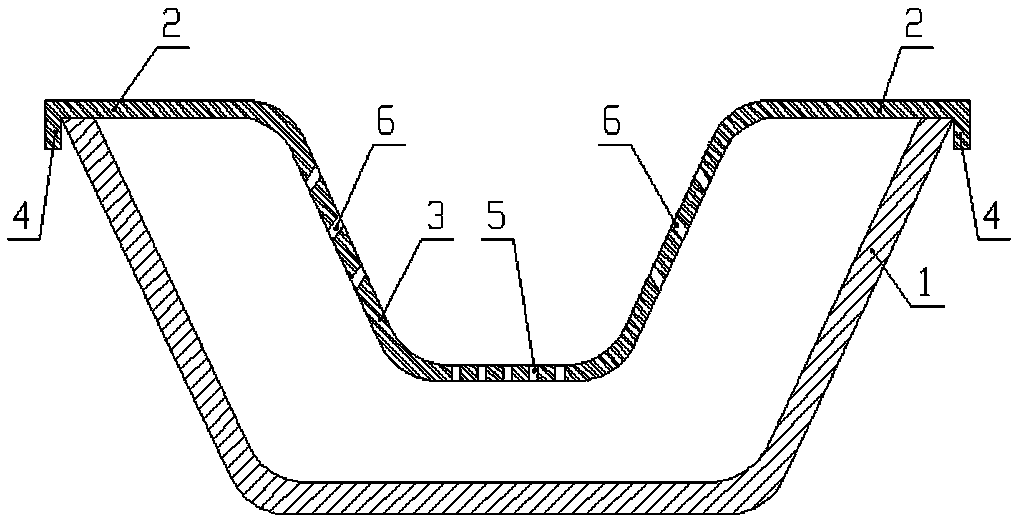

[0015] Such as figure 1 As shown, the bowl-shaped tungsten crucible of the present invention includes a crucible body 1 in a bowl-shaped structure and a carrier rack arranged in the crucible body 1, and the carrier rack is divided into a supporting part 2 located at the circumference and a loading part located in the middle 3. The support part 2 and the material loading part 3 form an integral structure. The support part 2 is built on the upper edge of the crucible body 1. The edge of the support part 2 is bent downward to form a rib 4 and is located outside the crucible body 1. The material loading part 3 is in the shape of a bowl shaped structure and located in the crucible body 1, the bottom surface of the loading part 3 is located above the bottom surface of the crucible body 1, the bottom surface of the loading part 3 is provided with blanking holes 5 at intervals, and the side of the loading part 3 is provided with ventilation holes 6 at intervals.

[0016] The connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com