A translational two-degree-of-freedom parallel flexible piezoelectric micro-motion platform

A technology of flexible structure and micro-motion platform, which is applied in the direction of instruments and instrument parts, etc., can solve the problems of large space occupation, small work surface, and small output displacement of the work platform, and achieve simple and compact structure, improved motion accuracy, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention not only enables the moving platform to output linear micro-displacement only along the x or y direction, but also enables it to output linear micro-displacement along the x and y directions at the same time. The specific implementation is as follows.

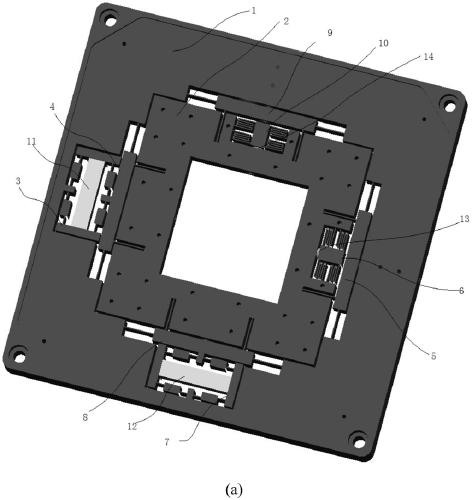

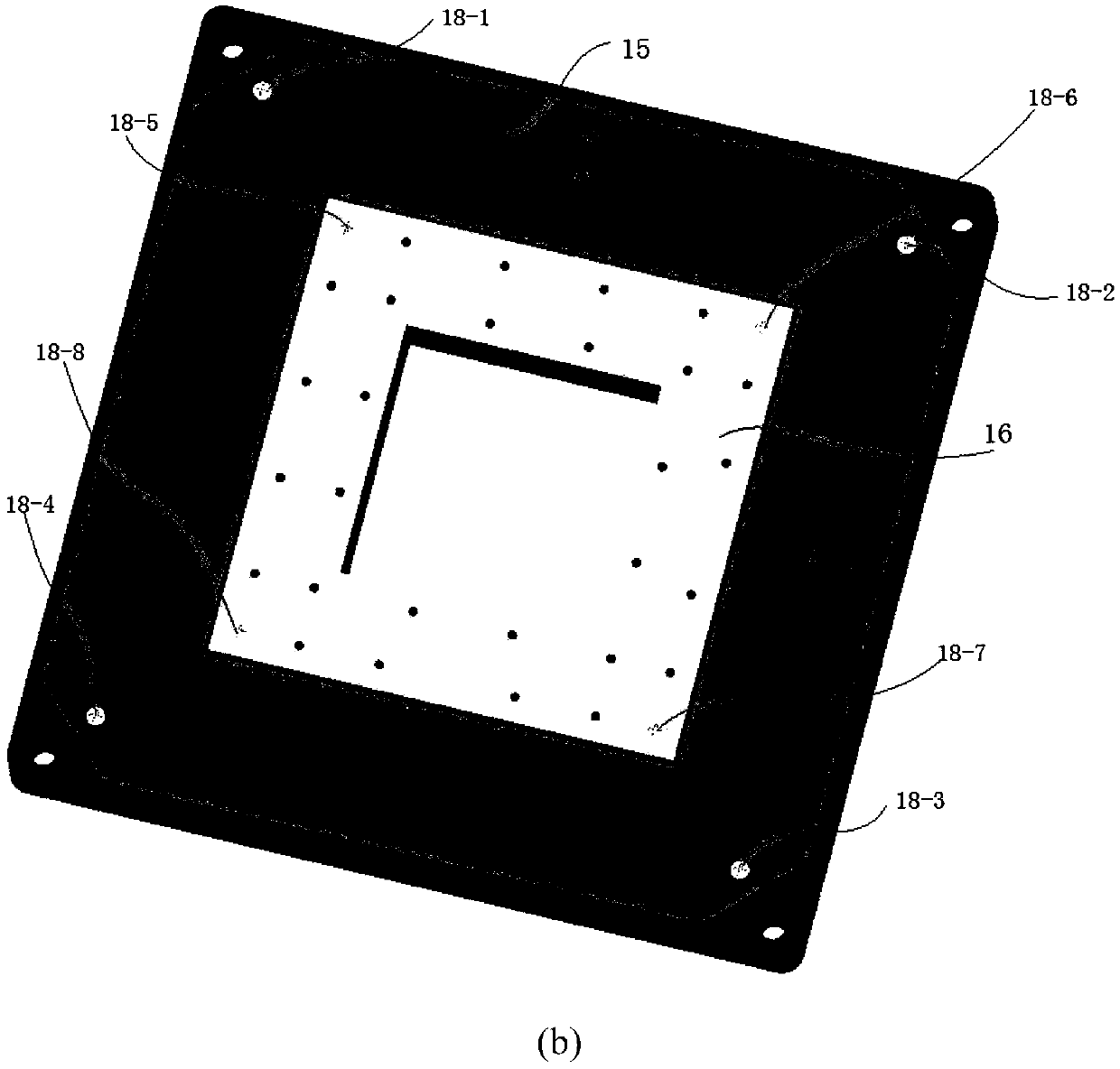

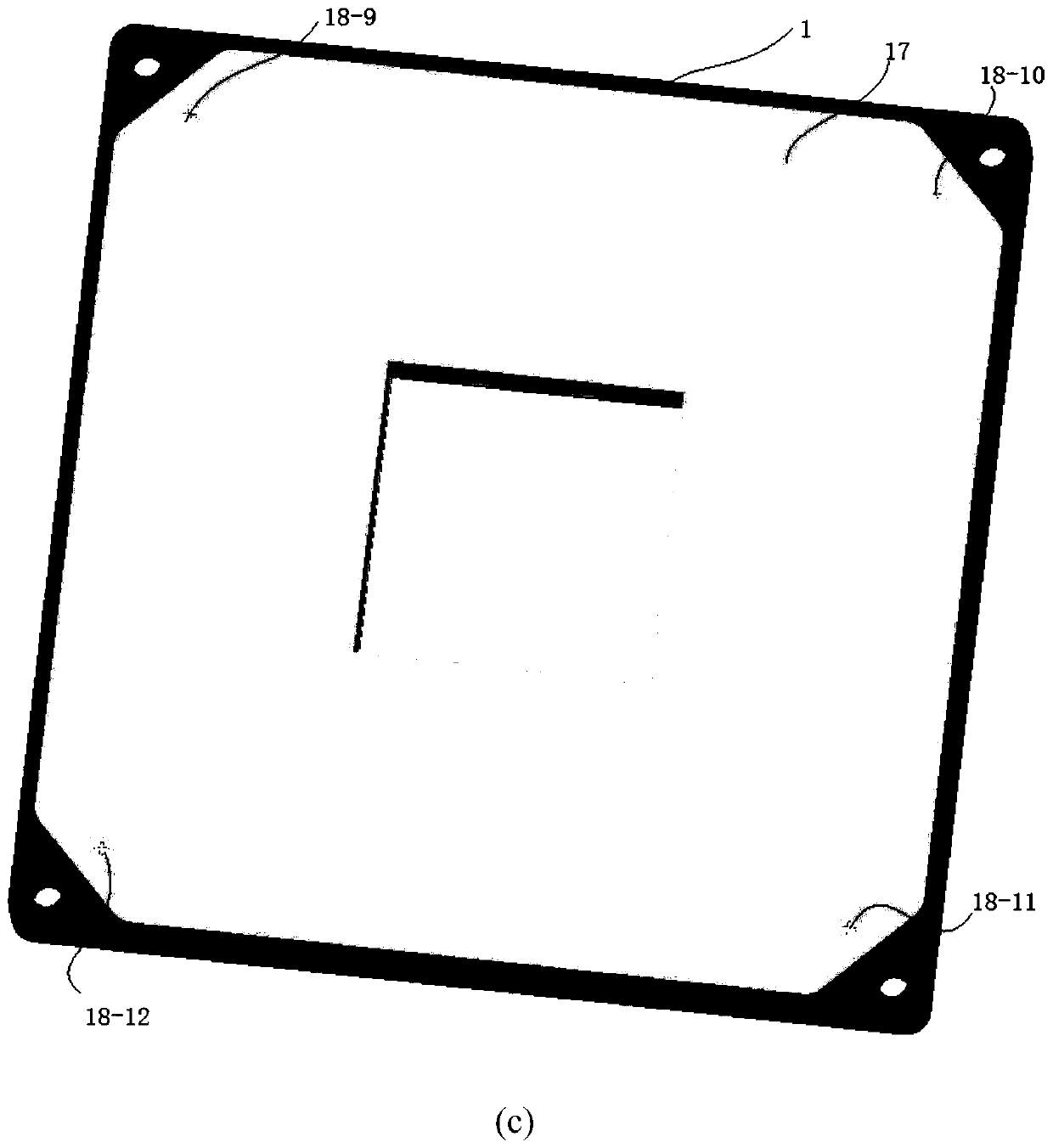

[0039] A piezoelectric micro-motion platform with a parallel flexible structure with translational two degrees of freedom, such as figure 1 As shown, it includes table body, piezoelectric actuator, adjusting screw, upper outer cover, upper inner cover, lower cover and set screw.

[0040] body (such as figure 2 As shown) includes fixed platform 1, moving platform 2, x-direction displacement amplification unit 3, x-direction displacement transmission unit 4, x-direction auxiliary unit 5, x-direction adjustment unit 6, y-direction displacement amplification unit 7, y-direction displacement transmission unit 8. The y-direction auxiliary unit 9 and the y-direction adjustment unit 10 are integrated stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com