Water pump

A technology for water pumps and pump bodies, which is applied in the direction of pump components, variable displacement pump components, and components of pumping devices for elastic fluids, etc., which can solve the problems of difficulty in reducing the radiation of the pump body itself, poor heat dissipation environment of the water pump, and protection of the water pump. Shutdown and other problems to achieve the effect of improving sound insulation and noise reduction, reducing impact, and weakening impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

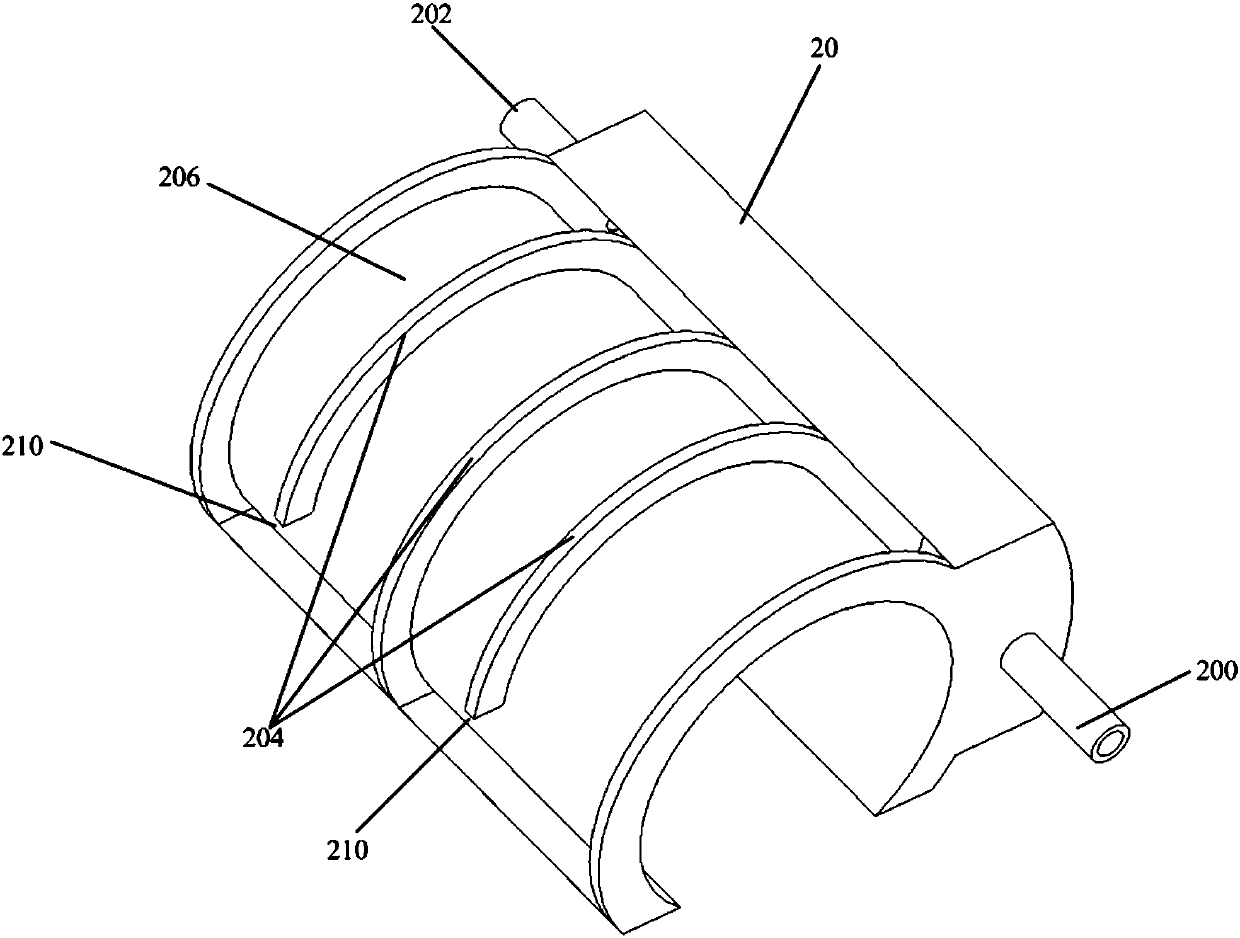

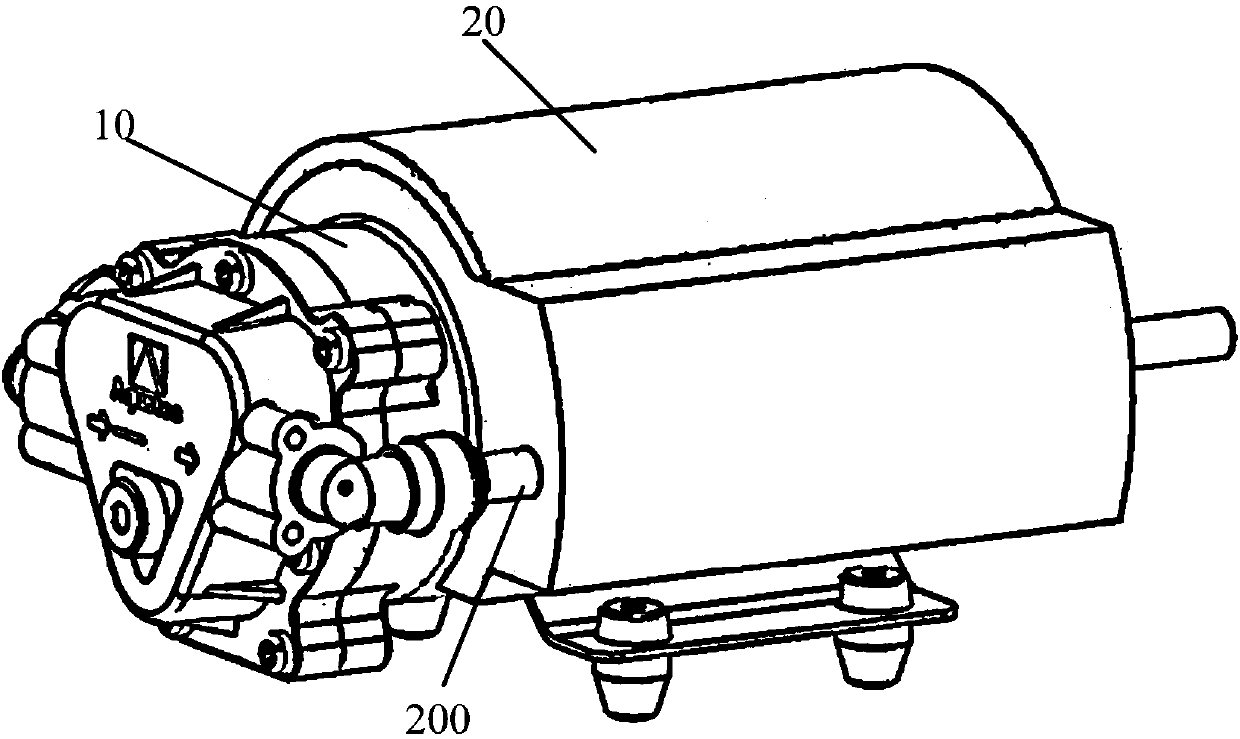

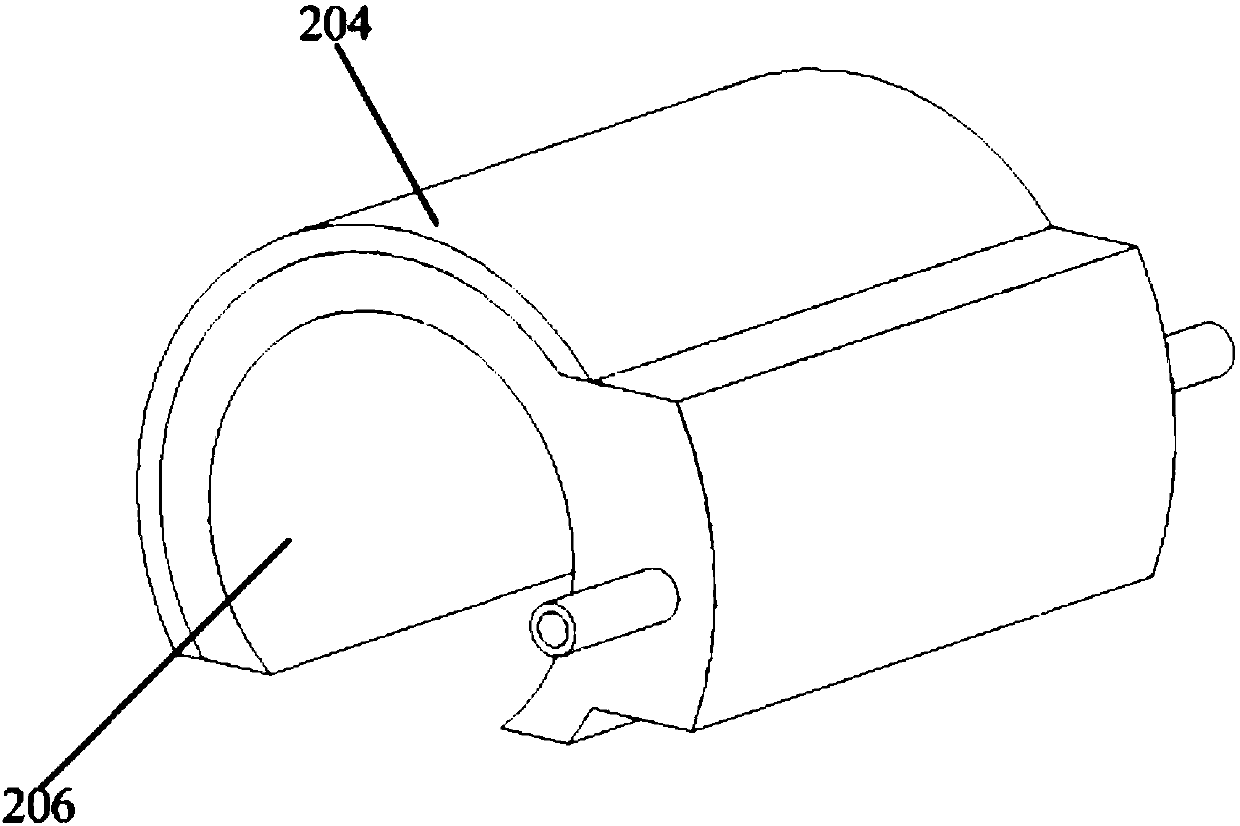

[0050] Such as Figure 1 to Figure 15 As shown, a water pump according to an embodiment of the present invention includes: a pump body 10, and a sound-insulating pulsation attenuation device 20, such as figure 2 , sleeved on the outside of the pump body 10, the sound insulation pulsation attenuation device 20 is hollow inside, including: an inner shell 206 and an outer shell 208 forming the inner cavity of the sound insulation pulsation attenuation device 20, and two end faces. Such as Figure 9 and Figure 10 ,and Figure 12 , Figure 14 , Figure 15 As shown, wherein, the inner shell 206, the outer shell 208 are concentric with the pump body 10, and are arranged along the radial direction of the pump body 10 in turn, the inner shell 206 is set between the pump body 10 and the outer shell 208, and the two end faces are along the pump body 10 is set in the direction of the centerline and is perpendicular to the centerline of the pump body 10 . The two end faces of the sou...

Embodiment 2

[0062] On the basis of Embodiment 1, this embodiment provides a manner in which the longitudinal channels 210 of the baffle 204 are distributed in the radial direction of the pump body 10 .

[0063] Such as Figure 16 As shown, the longitudinal passage 210 of the first baffle 204 of the present embodiment is between the baffle 204 and the housing 208; Being close to the water inlet makes the stress on the first baffle 204 more uniform, and the water flow can pass through the first longitudinal channel 210 faster, reducing the impact on the first baffle 204 and prolonging its service life. The longitudinal channel 210 of the second baffle 204 is between the baffle 204 and the inner shell 206 ; the longitudinal channel 210 of the third baffle 204 is between the baffle 204 and the outer shell 208 .

[0064] Through the technical solution of this embodiment, in the radial direction of the pump body 10, the projections of any two adjacent longitudinal passages 210 on the end face ...

Embodiment 3

[0067] Combining Embodiment 1 and Embodiment 2, in this embodiment, the longitudinal passages 210 on the three baffles 204 are dislocated in the circumferential direction and the radial direction at the same time, that is, in the radial direction and the circumferential direction of the pump body 10, The purpose is that the projections of any two adjacent longitudinal passages 210 on the end face of the sound insulation and pulsation attenuation device 20 do not completely coincide.

[0068] Specifically, as Figure 17 As shown, in this embodiment, only the longitudinal channel 210 on the second baffle plate 204 is arranged at the position of the middle part of the baffle plate 204, which is partial to the housing 208, so that the longitudinal channels 210 on the three baffle plates 204 can be The dislocation setting in the radial direction and the circumferential direction, and because the longitudinal channel 210 on the second baffle plate 204 is located in the center, short...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com