A kind of preparation method of optical film and product thereof

A technology of optical films and products, applied in optics, optical components, nonlinear optics, etc., can solve problems such as high cost and large phase difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Implementation example 1 relates to an optical film with free-form lenses on both surfaces. For details, please refer to figure 1 and image 3 . Proceed as follows:

[0097] 1) Set the position of the light source as (0.00,0.00), the position of the intersection of the front surface S1 and the horizontal axis (3.00,0.00), the position of the intersection of the back surface S2 and the horizontal axis (10.50,0.00), and the thickness of the substrate d=0.188mm.

[0098] 2) Set the maximum angle θ at which the light source enters the virtual lens max = 60°.

[0099] 3) In the range of [0,60], with 0.05° as the division unit, obtain a series of θ 1i , where θ 1(i+1) = θ 1i +0.05, i=1~1200.

[0100] 4) Bring i=1, 2, 3, ..., 1200 into the following function groups in turn:

[0101]

[0102] In the above group of functions, (x 1i ,y 1i ) is the angle θ emitted by the light source 1i and θ 1i-1 The intersection coordinates of the ray and the front surface S1. (x...

Embodiment 2

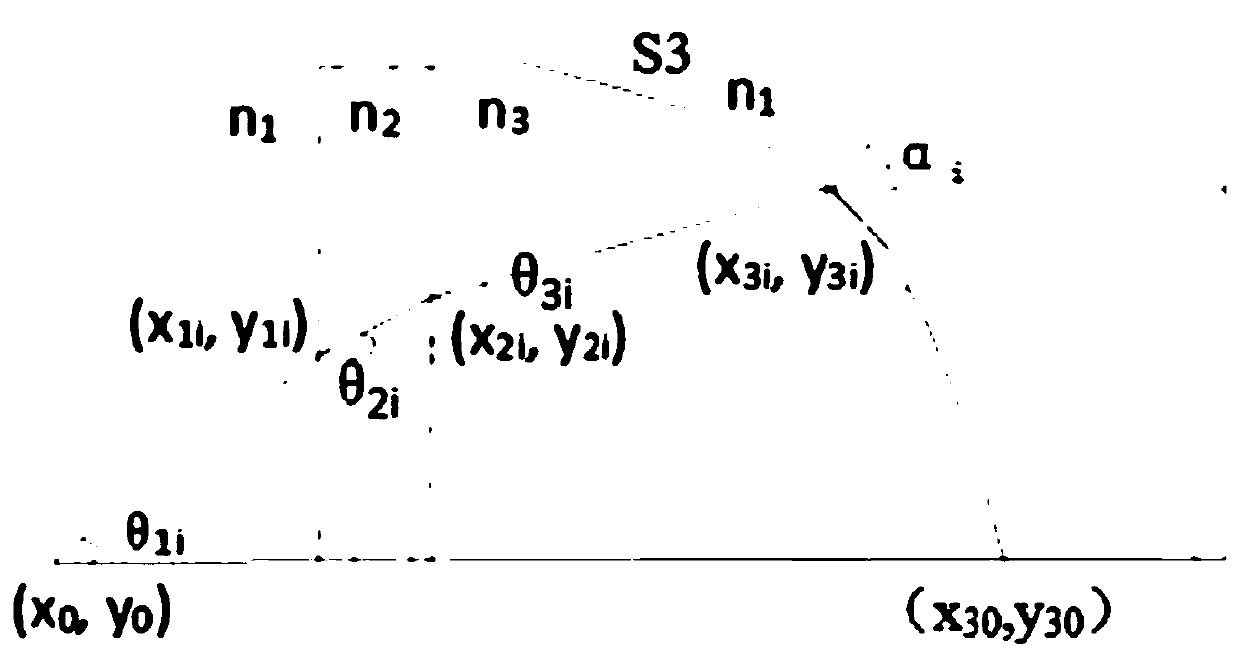

[0115] Implementation example 2 relates to an optical film with a free-form surface lens on a single surface. For details, please refer to figure 2 and Figure 5 . Proceed as follows:

[0116] 1): Determine the position of the light source (0.00, 0.00), the position of the intersection of the curved surface S3 and the horizontal axis (8.50, 0.00), and the thickness of the substrate d=0.188mm.

[0117] 2): Set the maximum angle θ at which the light source enters the virtual lens max = 60°. ;

[0118] 3): In the range of [0,60°], start at 0°, divide every 0.02°, and obtain a series of θ 1i , where θ 1(i+1) = θ 1i +3000, i=1~3000.

[0119] 4) When i=1, the angle θ=θ of the light emitted by the light source 11 = 0°, put in the following formula to solve (x 31 ,y 31 ):

[0120]

[0121] In the above formula, (x 1i ,y 1i ), (x 2i ,y 2i ) and (x 3i ,y 3i ) are respectively the angle θ emitted by the light source 1i The coordinates of the intersection of the ray w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com