Positioning hole milling equipment for bamboo plywood

A technology of bamboo plywood and positioning holes, which is applied to fixed drilling machines, wood processing appliances, bark areas/debris/dust/waste removal, etc., which can solve problems such as easy cracks and damage to wooden boards, and avoid cracks , high practicability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

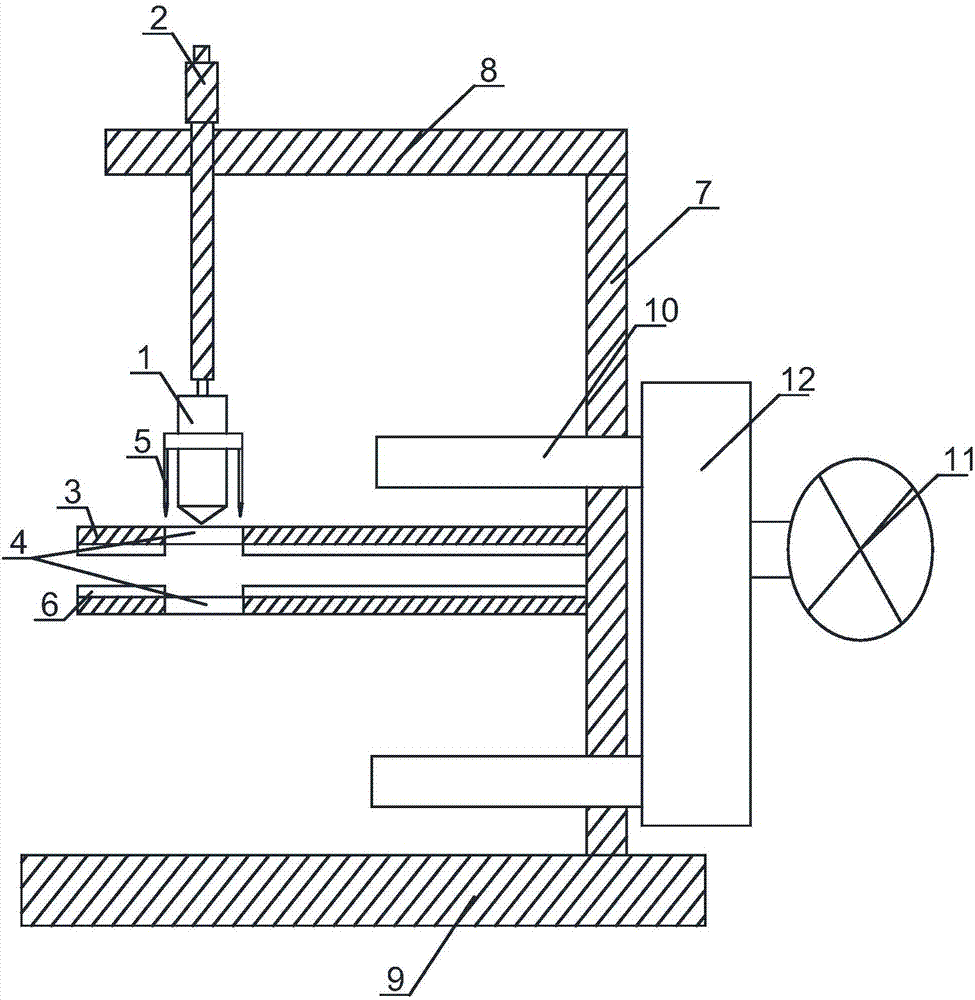

[0022] Such as figure 1 As shown, a positioning milling device for bamboo plywood of the present invention includes a drill bit 1 that rotates downwards, an automatic feed drilling power head 2 that drives the drill bit 1, and two horizontally placed fixing plates are arranged below the drill bit 1 3. The two fixed plates 3 are arranged in parallel in the vertical direction. There is a space between the two fixed plates 3 for the insertion of the wooden board that needs to be punched. The two fixed plates 3 are provided with positioning holes 4. The positioning holes 4 The hole diameter of the hole to be processed on the wooden board is the same, and two positioning holes 4 with the same central axis and the same diameter in the vertical direction cooperate to fix the drilling position of the wooden board, and the outside of the drill bit 1 is provided with multiple cutting needles 5. The cutting pins 5 are evenly distributed around the circumference of the drill bit 1 , the c...

Embodiment 2

[0025] Based on Embodiment 1, one side of the two fixed plates 3 is provided with a support rod 7 for fixing the two fixed plates 3, and the support rod 7 is perpendicular to the fixed plates 3, and the support rod 7 is provided with two fixed plates. 3 slide rails that slide up and down. The upper end of the support rod 7 is provided with a fixing frame 8 for fixing the automatic feeding drilling head 2 , and a base 9 is provided below the support rod 7 .

[0026] The rail is used to adjust the space distance between the fixed boards, which is suitable for wooden boards of different thicknesses and has a wide range of applications. The fixing frame, the base, and the support rod are the skeleton of the whole device, which play a supporting and fixing role, and provide a workbench for the processing of wooden boards.

Embodiment 3

[0028] Based on the above-mentioned embodiment, a slag discharge pipe 10 is arranged on the upper side of the fixed plate 3 at a relative position and below the fixed plate 3 at a relative position below. A box body 12 is arranged between the pipe 10 and the exhaust fan 11 . The suction force of the exhaust fan can suck the wood slag around the fixed plate into the box body, which plays a role in recycling the wood slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com