Self-breakage rail mechanism for thick-fine combined conveying system

A conveying system, self-disconnecting technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of unfavorable thick and thin connection systems, time-consuming and labor-intensive operations, etc., to facilitate maintenance, reduce reaction time, The effect of reducing economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

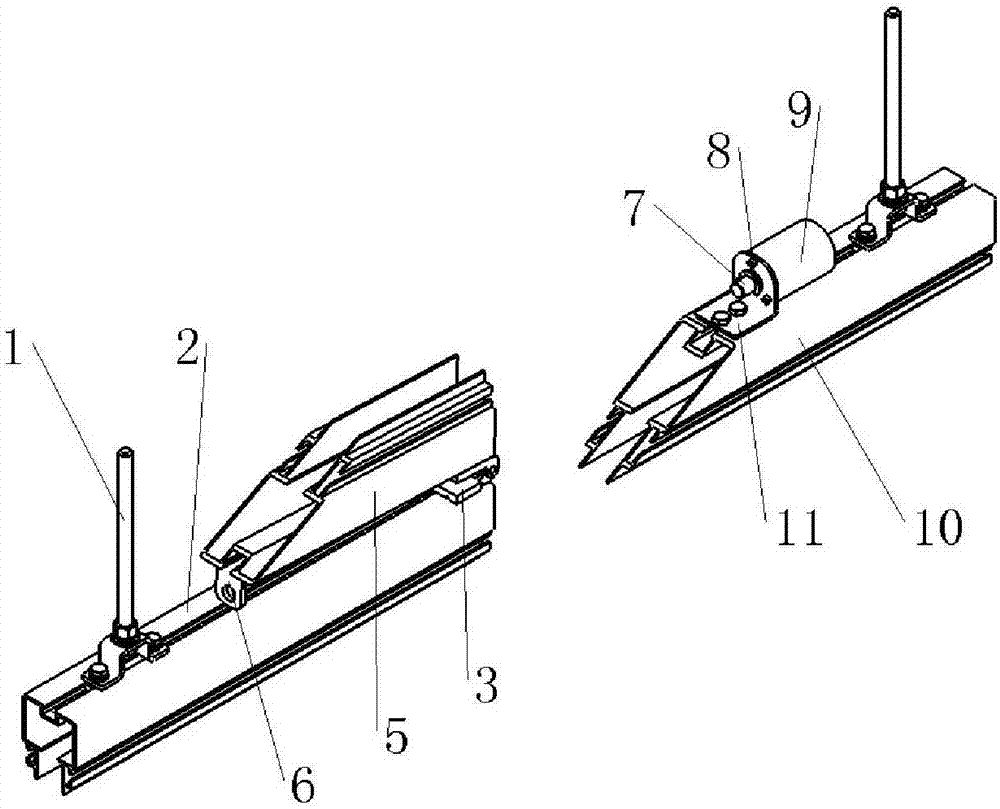

[0027] Embodiment: The thick-thin conveyor system builds the track line according to the special construction drawing, and installs the self-breaking track mechanism at the required position, such as the space required for the lifting of the fire shutter door, the area convenient for system maintenance, etc.

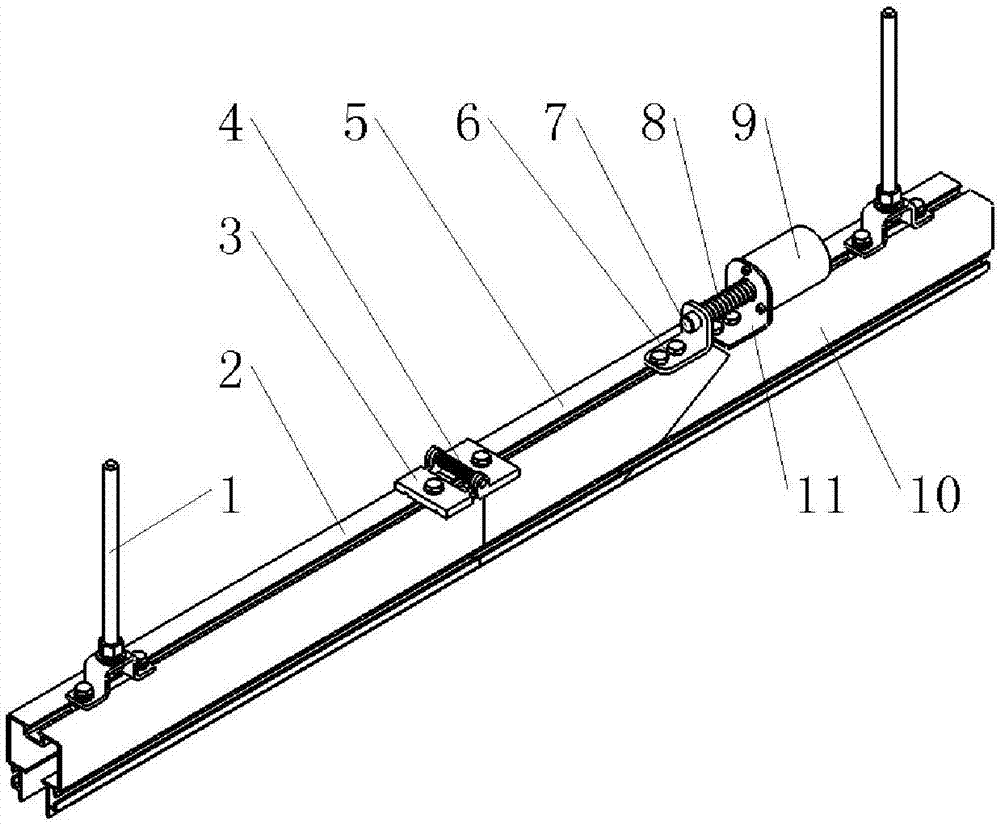

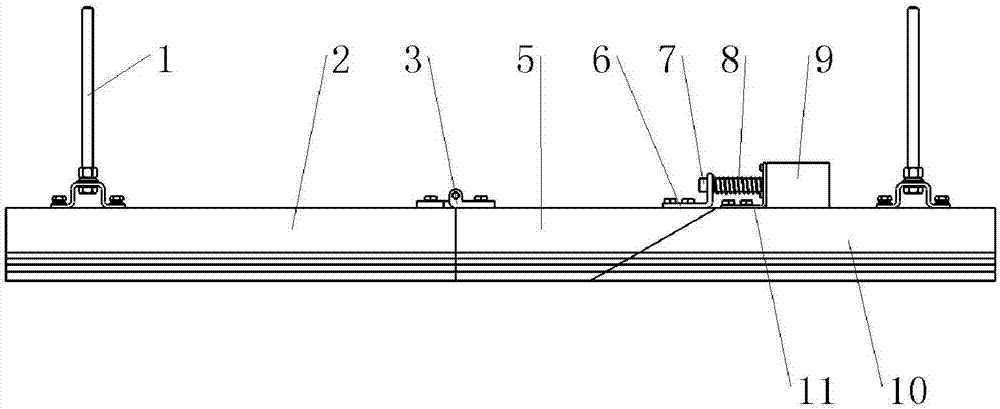

[0028] Mounting slots are provided on the top surfaces of the universal track 2, the self-breaking track 5 and the beveled track 10, and the hanging component 1, the hinge component, the positioning plate 6 and the electromagnet 9 can be respectively fixed by standard component components of different specifications. It is connected to the top surface of different tracks, wherein, one hinge of the suspension assembly 1 and the hinge assembly is respectively fastened to both ends of the common rail 2, and the positioning plate 6 and the other hinge of the hinge assembly are fastened to the self-breaking track 5 The positioning plate 6 is located at the oblique end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com