Corrosion resistant supporting pipe

A support pipe and anti-corrosion technology, applied in the field of anti-corrosion support pipes, can solve the problems of easy rusting and damage of the inner wall, and the pipe body is not easy, and achieve the effects of avoiding corrosion, increasing the adhesion area, and being difficult to imitate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the drawings and embodiments. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

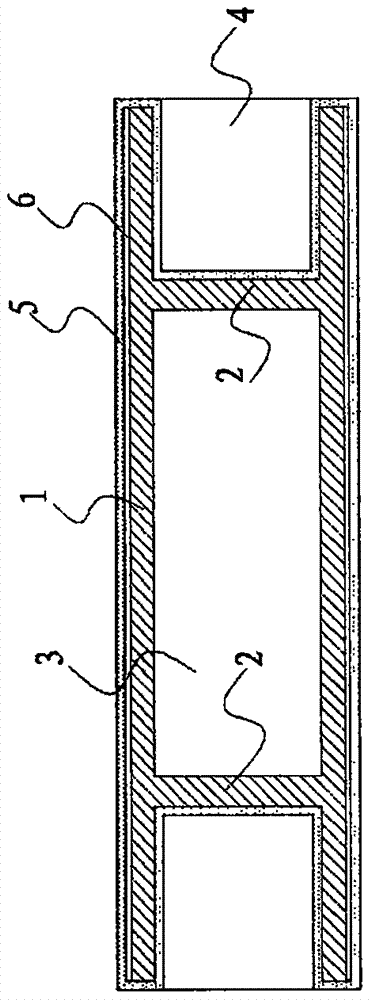

[0011] Such as figure 1 As shown, an anti-corrosion support pipe includes a pipe body 1 made of steel. A spacer 2 is provided on the inner wall of the pipe body 1 near the end of the pipe body 1, and the pipe body 1 and The inner surface of the spacer 2 is enclosed to form a sealed area 3; the end of the tube body 1 and the outer surface of the spacer 2 form an open area 4; the outer wall of the tube body 1 is provided with a convex rib 6 along the axial direction It is provided that the cross section of the rib 6 is triangular, the tip of the triangular rib 6 faces outward, and the outer wall of the tube body 1, the rib 6 and the open area 4 are coate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com