Steel for high-strength aluminum-clad substrate and production method thereof

A production method and high-strength technology, applied in the field of low-alloy steel manufacturing, can solve the problems of high composition and poor heat dissipation of wheels, and achieve the effects of reducing production costs, good interface bonding characteristics, and excellent plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

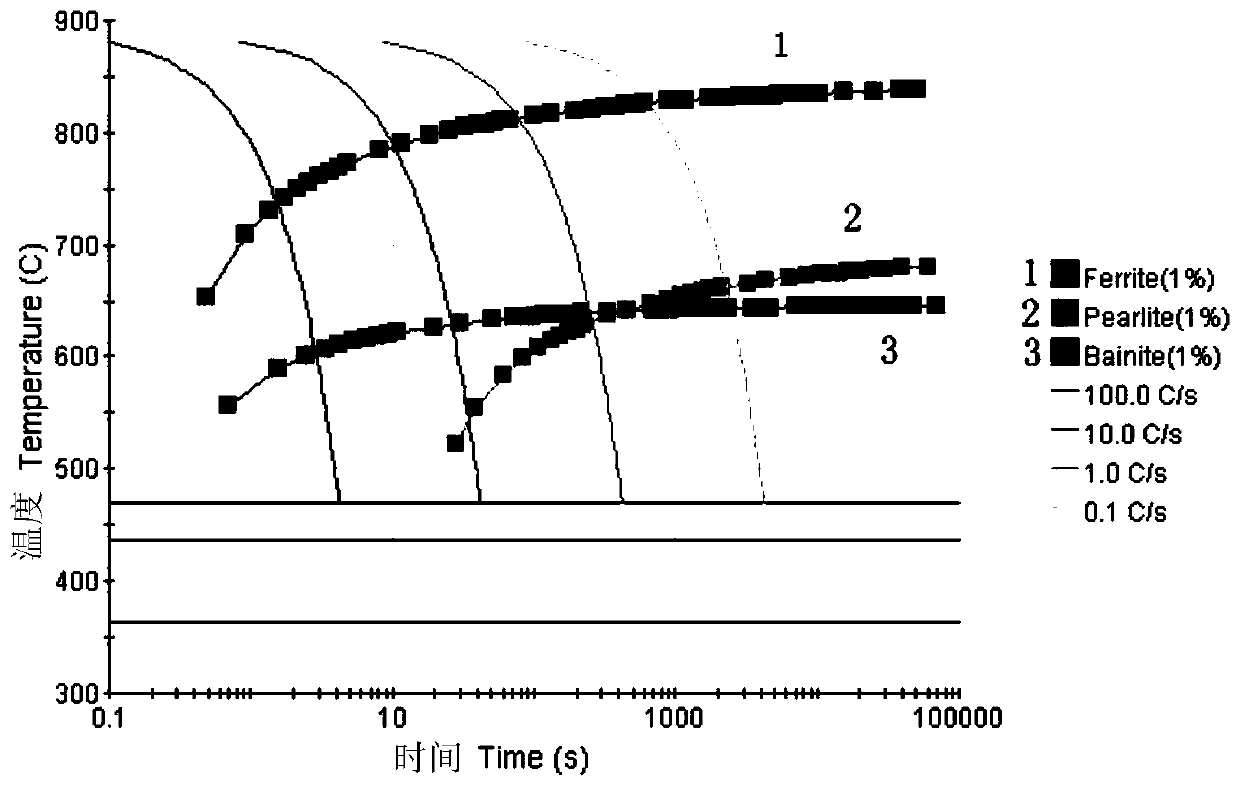

[0044] According to the steel chemical composition requirements of the present invention, steelmaking is carried out in a 500kg vacuum induction furnace, and the obtained chemical composition is shown in Table 1, and cast into a 100kg steel ingot, the heating temperature is 1200°C, the final rolling temperature is 880-920°C, and the coiling temperature is 540-640°C .

[0045] The mechanical properties of the steel examples of the present invention are shown in Table 1. Comparing the composition and performance with similar steel types. Wherein comparative example 1 is Chinese patent publication number CN1056535A "a kind of steel for automobile rolling wheel", comparative example 2 is Chinese patent publication number CN101280389A "a kind of steel strip for automobile wheel spoke and its manufacturing method", comparative example 3 is Chinese Patent Publication No. CN101550519A "A hot-rolled dual-phase steel plate for wheels and its production method".

[0046] Comparative ex...

Embodiment 2

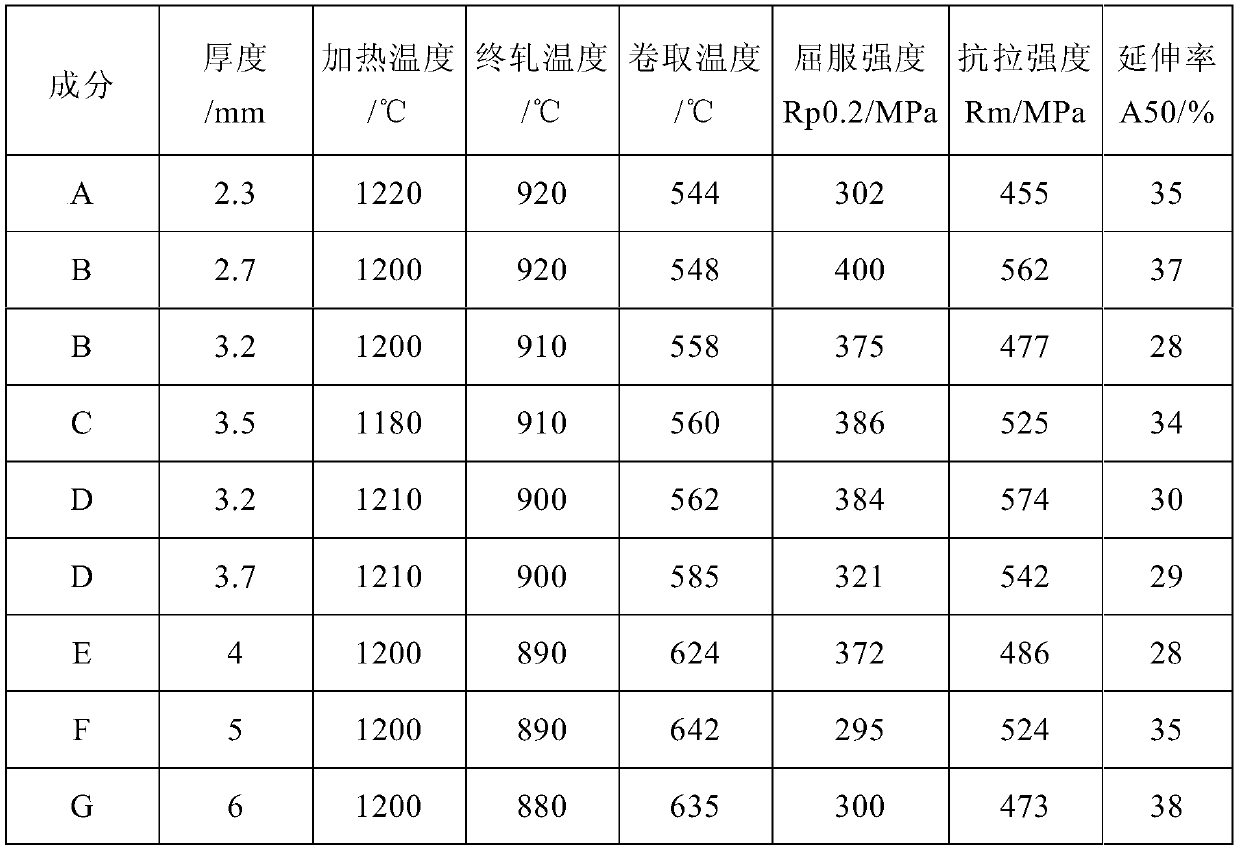

[0050] According to the composition requirements of the present invention, the steel of the present invention is smelted on a 500kg vacuum induction furnace in a laboratory. The chemical composition is shown in Table 1. The billet heating temperature is above 1180-1230°C, the final rolling temperature is 880-920°C, the coiling temperature is 540-640°C, and then air-cooled to room temperature. The mechanical properties are shown in Table 2.

[0051] Table 1 steel embodiment of the present invention - chemical composition (wt%)

[0052] Element C Si mn P S Al O N Ti Ca (O+N) / P+S A 0.031 0.005 0.43 0.0121 0.0062 0.0011 0.0065 0.0065 0.012 0.0022 0.71 B 0.037 0.001 0.44 0.0068 0.0059 0.0012 0.0492 0.0140 0.013 0.0031 4.98 C 0.042 0.001 0.46 0.058 0.0035 0.0018 0.0061 0.0082 0.010 0.0023 0.23 D 0.053 0.005 0.53 0.0111 0.0040 0.0012 0.0340 0.0148 0.016 0.0023 3.23 E 0.057 0.002 0.62 0.0073...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com