Oil tube clamping and positioning device

A clamper and tubing technology, which is used in wellbore/well components, earthwork drilling, etc., can solve problems such as the lack of universality of the clamper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

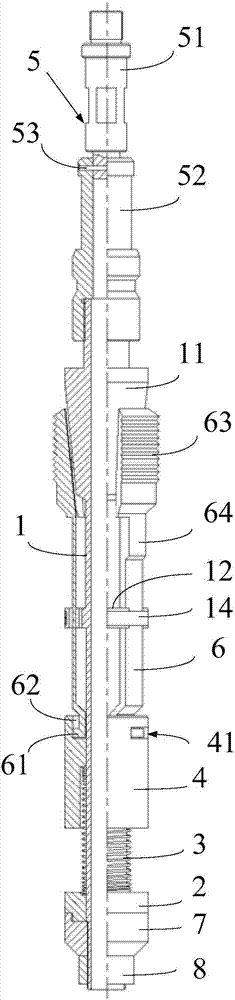

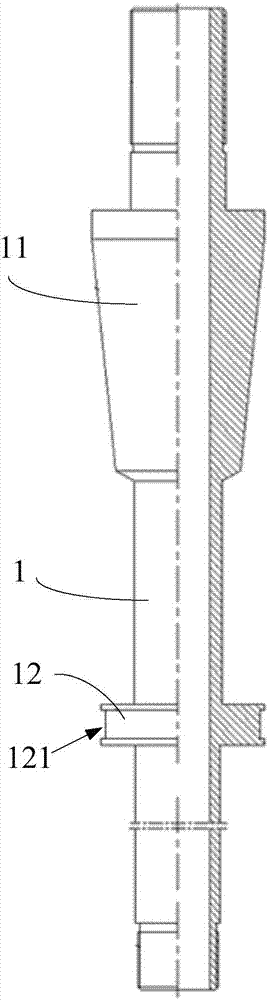

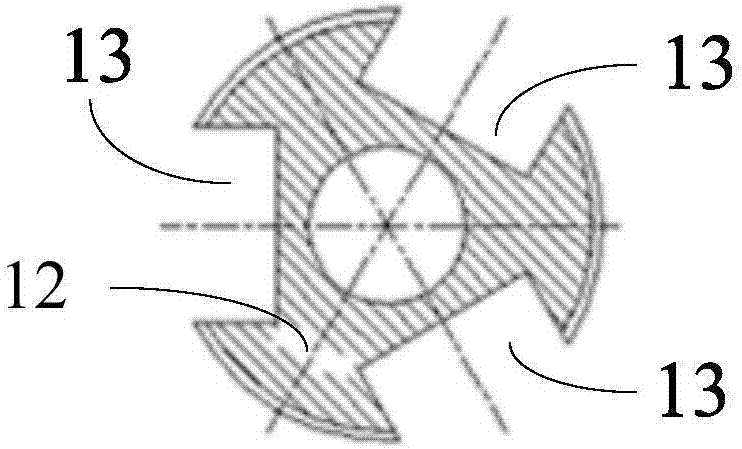

[0026] The embodiment of the present invention provides an oil pipe retainer, such as figure 1 As shown, the tubing retainer includes a central tube 1, a temperature-controlled magnetic steel 2, an elastic member 3, a slip seat 4, a fishing assembly 5 and three slips 6, and the temperature-controlled magnetic steel 2 is fixedly set on the central tube 1. The bottom of the bottom, the slip seat 4 is a ferromagnetic member, the slip seat 4 is slidably set on the central tube 1 and is located above the temperature control magnet 2, and the elastic member 3 is arranged on the slip seat 4 and the temperature control magnet 2 Between them, the three slips 6 are equidistantly arranged in the circumferential direction with the center tube 1 as the central axis, and the bottoms of the three slips 6 are all movably clamped with the top of the slip seat 4, and the outer peripheral wall of the center tube 1 corresponds to The position of the top of the slips 6 is provided with a frustum 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com