Sunken engine unit test bench structure

An engine unit and test bench technology, applied in the field of comprehensive testing, can solve the problems of large pollution and strong subjectivity in comprehensive testing, and achieve the effects of reducing labor consumption, improving convenience, and isolating noise and vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

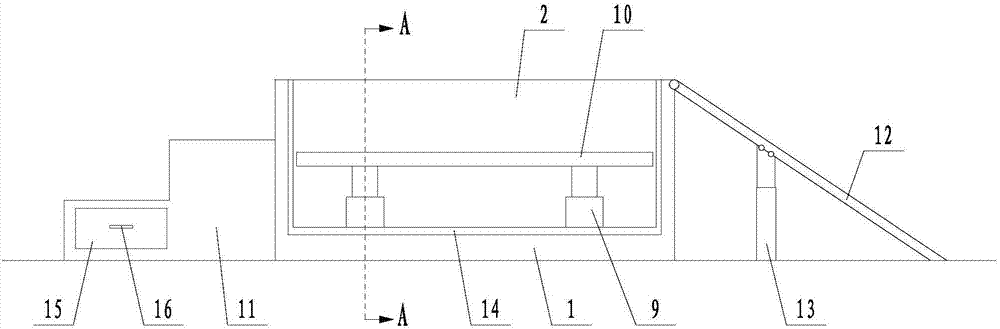

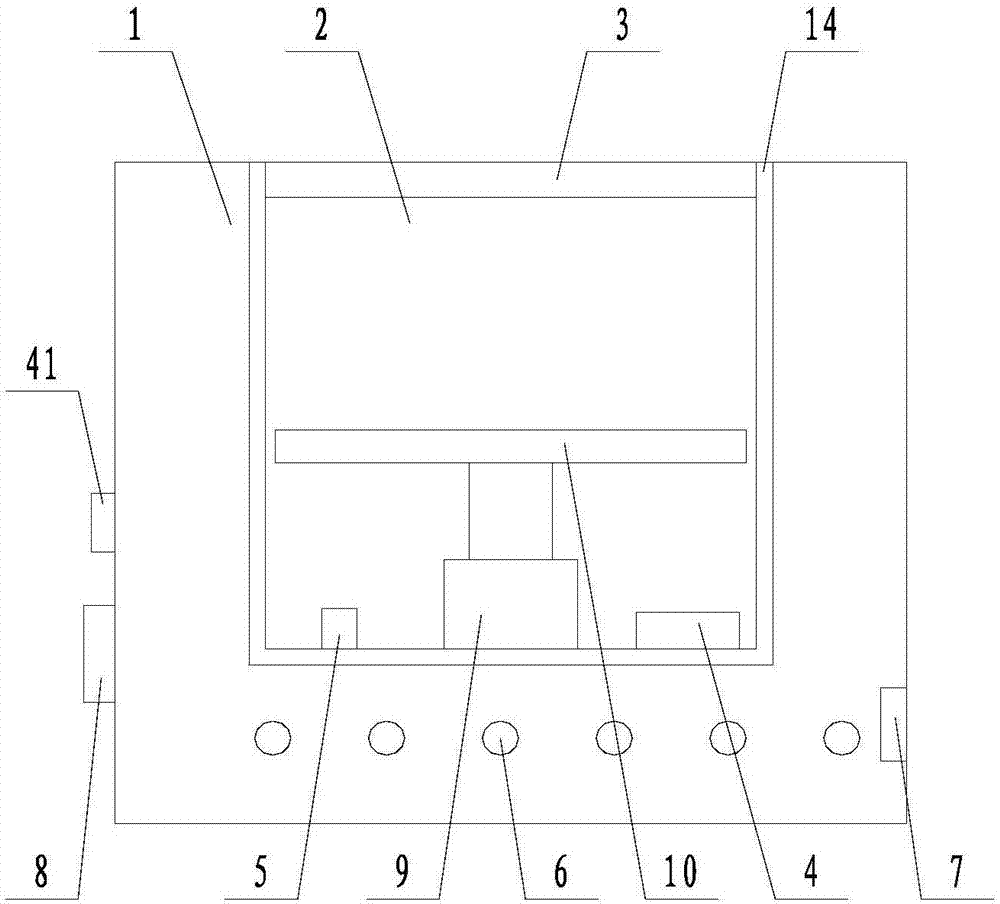

[0024] Such as figure 1 and figure 2 The shown sunken engine unit test platform structure includes a boss 1, and the opposite sides of the boss 1 are respectively provided with stairs 11 and support plates 12, and the stairs 11 are detachably connected with the boss 1, and the support The plate 12 is hinged with the boss 1, the top of the support plate 12 is coplanar with the upper surface of the boss 1, and the bottom surface of the support plate 12 is hinged with the telescopic rod 13; the groove 2 is arranged above the boss 1, and a layer of porous sound-absorbing board is laid on the inner wall of the groove 2 14. A lifting platform is set on the inner bottom of the groove 2, an openable cover 3 is set on the upper end of the groove 2, a humidifier 4 and a humidity sensor 5 are set inside the groove 2, and several vibration sensors are set inside the boss 1 6. It also includes a storage 7 and a display screen 8 arranged on the surface of the boss 1 , the input end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com