Artificial core preparation method for fracturing performance testing of rocks containing controllable fractures

An artificial core and rock technology, applied in the field of artificial core preparation, can solve the problems of providing rock samples with controllable fractures, etc., and achieve the effects of low cost, simple operation and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

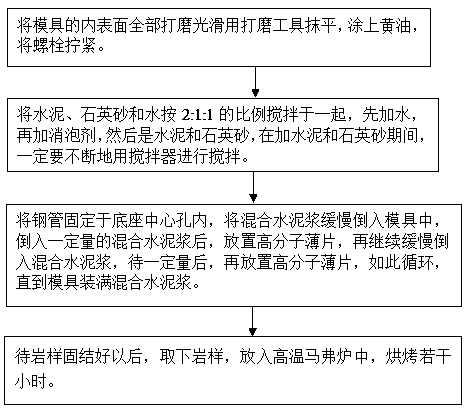

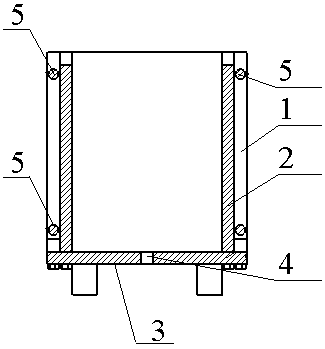

[0026] combine figure 1 As shown, this artificial core preparation method for testing the fracturing performance of rocks with controllable fractures:

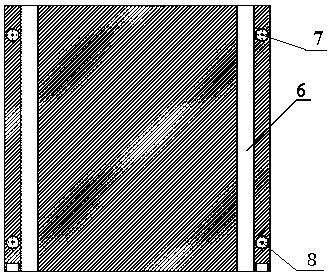

[0027] Preparation of mixed cement slurry: Before making the rock sample, first polish the inner surface of the mold to smooth and apply butter, specifically: first, use a grinder to smooth the inner surfaces of the two outer steel plates 1, two inner steel plates 2 and the base 3, and use The bolts fix the two outer steel plates 1, the two inner steel plates 2 and the base 3, and at the same time apply butter evenly inside them. Using 425# cement, mix cement, water and quartz sand together in a ratio of 2:1:1 to make a cube rock sample with a side length of 300mm, in which the thickness of the polymer sheet is 0.1mm, the length is 3cm, and the width is 2cm.

[0028] When making mixed cement slurry: Stir cement, quartz sand and water together in a ratio of 2:1:1, add water first, then add defoamer, and then cement and quartz ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com