Optical detection equipment

An optical detection and equipment technology, applied in the field of optical detection equipment, can solve the problems of large subjective judgment factors, low efficiency, and unguaranteed quality, and achieve the effects of convenient and fast adjustment, increased installation space, and high installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

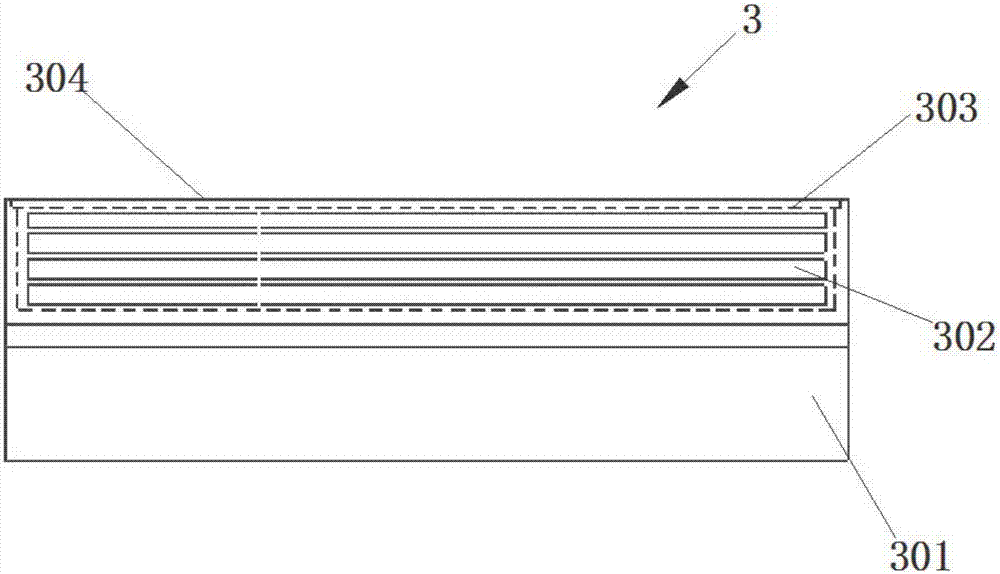

[0051] image 3A side view of a target according to the invention is schematically represented. According to an embodiment of the present invention, the target 3 includes a casing 301 , a light source 302 , a light source diffusion plate 303 and a target plate 304 . In this embodiment, the target plate 304, the light source diffusion plate 303 and the light source 302 are arranged in order from top to bottom, the target plate 304 and the housing 301 form a closed space, and the light source 302 and the light source diffusion plate 303 are located 301 in the confined space formed. The light source 302 adopts an LED annular uniform light source, and the target plate 304 is a film target plate with vertical and horizontal lines.

[0052] Figure 4 Schematic representation of a perspective view of a black box that can accommodate an optical detection device according to the invention. According to an embodiment of the present invention, the black box 6 is a square hollow box a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com