Bi-directional piston double row type high efficiency pump device for agricultural chemical sprayer

A two-way piston and sprayer technology, applied in piston pumps, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as large production costs, and achieve the effects of improved performance, strong performance, and convenient assembly and combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

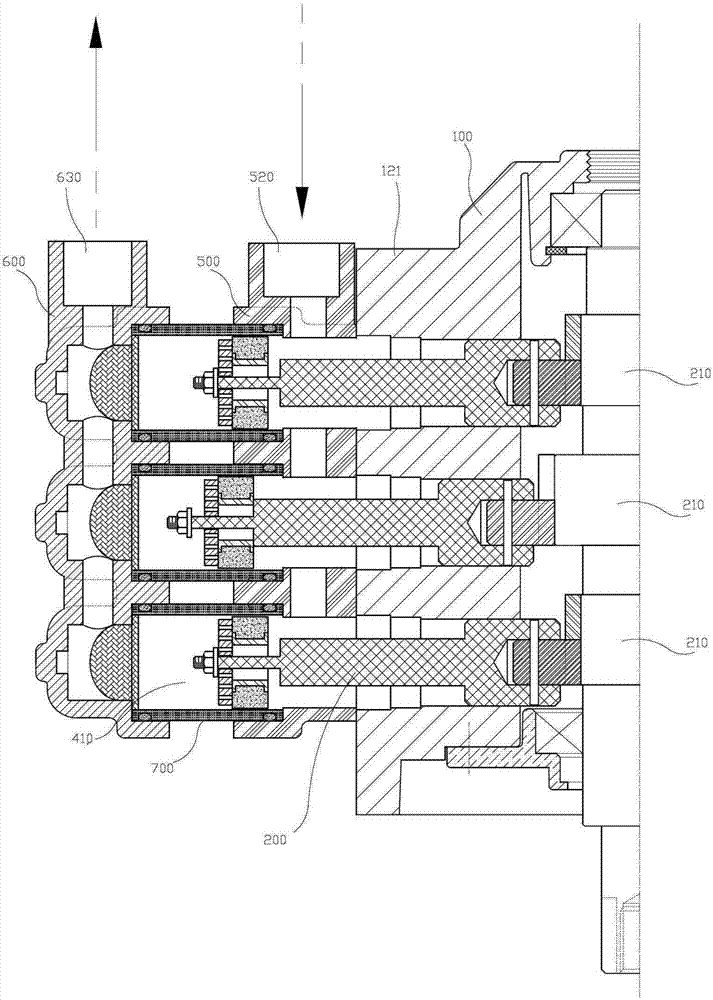

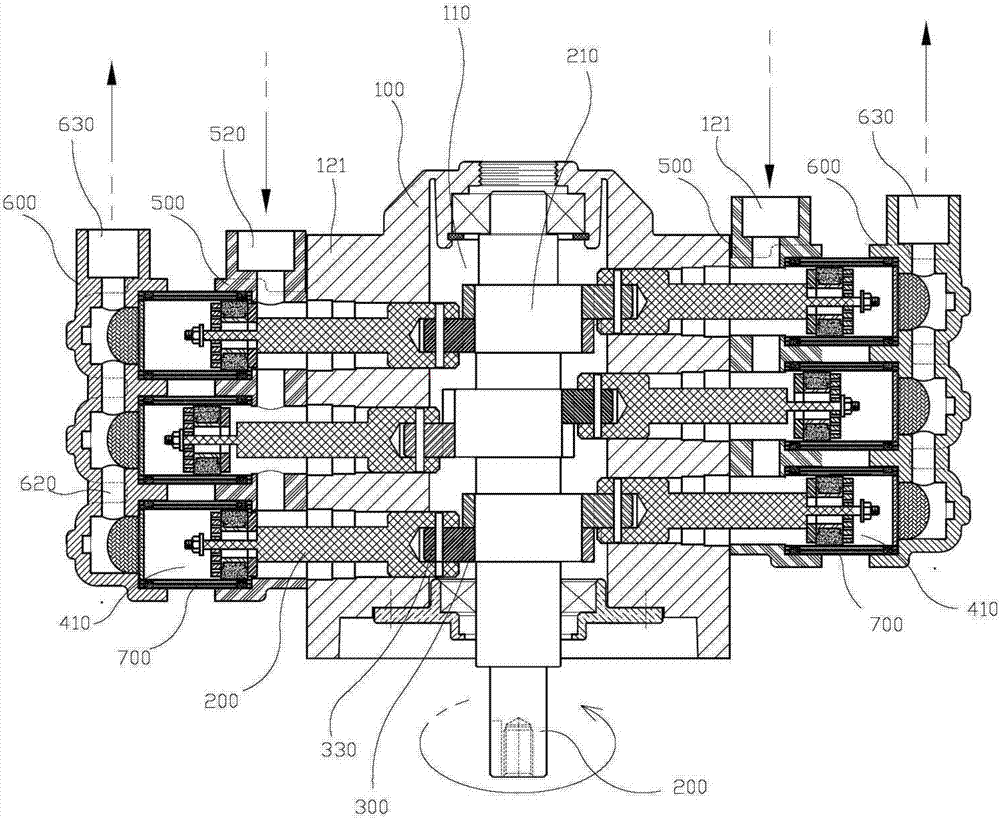

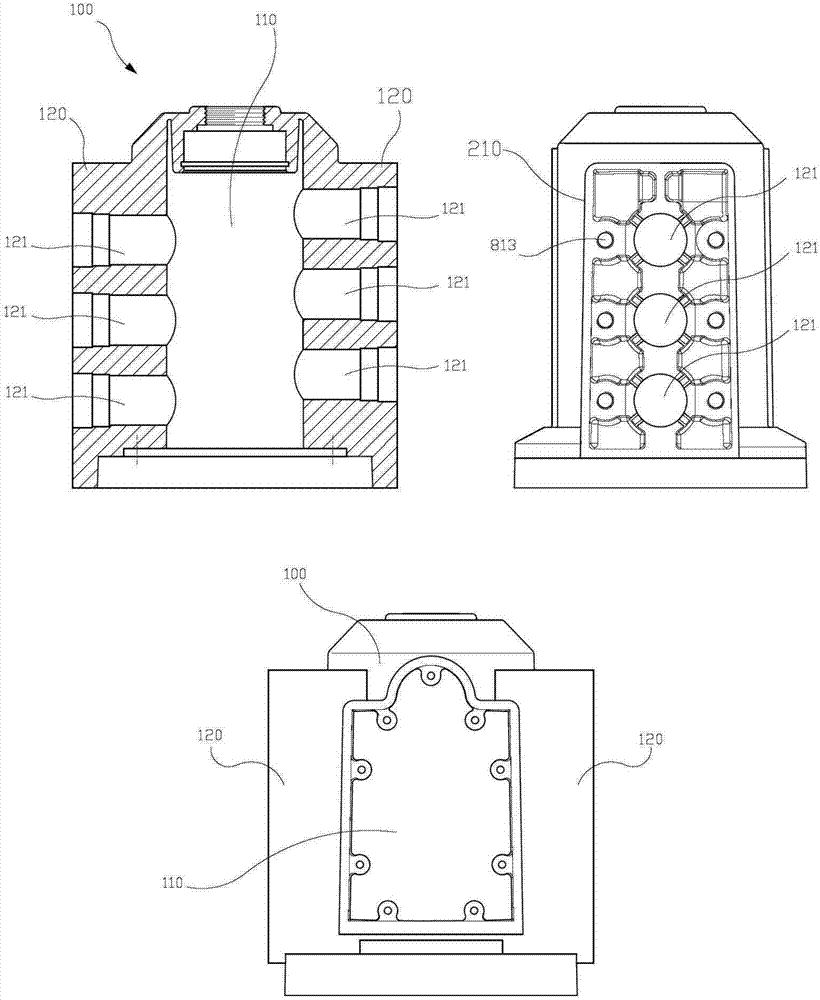

[0029] A two-way piston high-efficiency pump for a pesticide sprayer, in which a shaft installation space 110 is formed in the center of the outer casing 100 . The pumping operation chambers 120 on the left and right sides of the shaft installation space 110 are integrally formed with the outer casing 100, respectively. Each of the pumping operation chambers 120 on the left and right sides is provided with a cylinder communication groove 121 that communicates with the shaft installation space 110 outward, and a plurality of them are arranged at certain intervals;

[0030] In the present invention, a drive motor (not shown) is provided in the shaft installation space 110 of the outer casing 100 to drive the rotation shaft 200 to rotate vertically. Multiple sets of eccentric wheels 210 on the rotating shaft 200 are arranged and installed at intervals;

[0031] Two set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com