Robot hand and transporting robot

A robot arm and robot technology, applied in the field of conveying robots, can solve problems such as impossible to enter the box, thickening of the thickness, and the inability of the robot arm to enter the box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

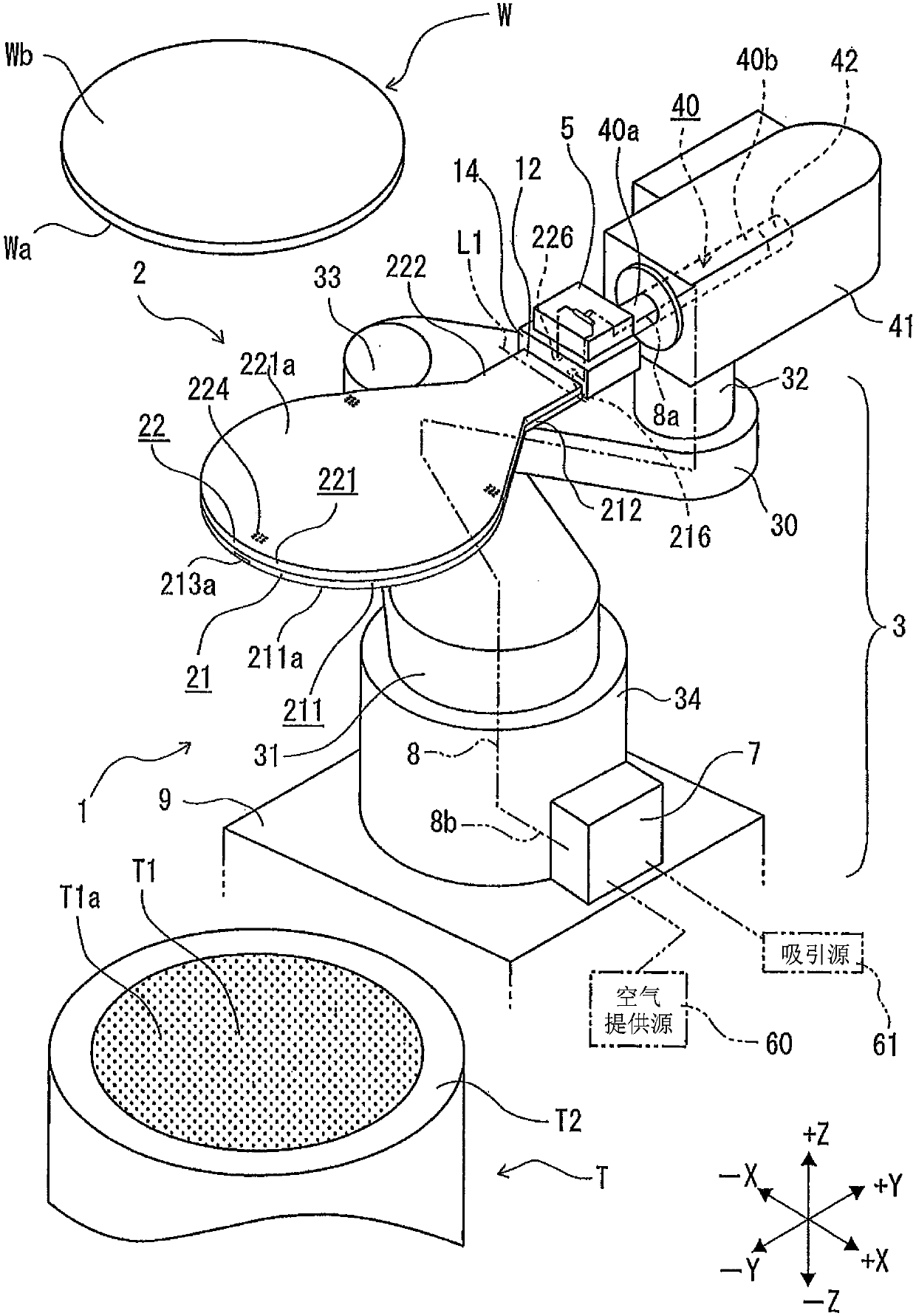

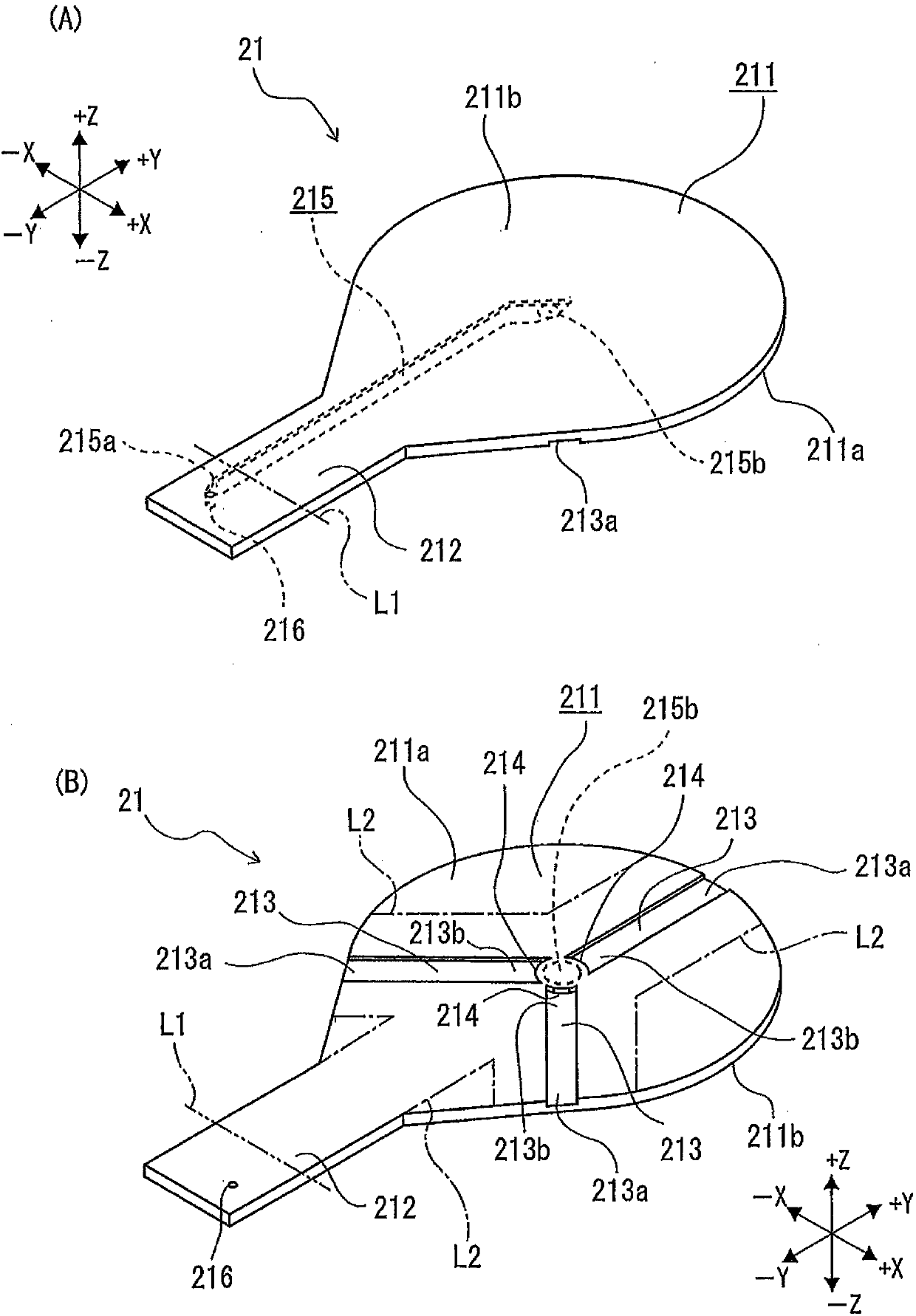

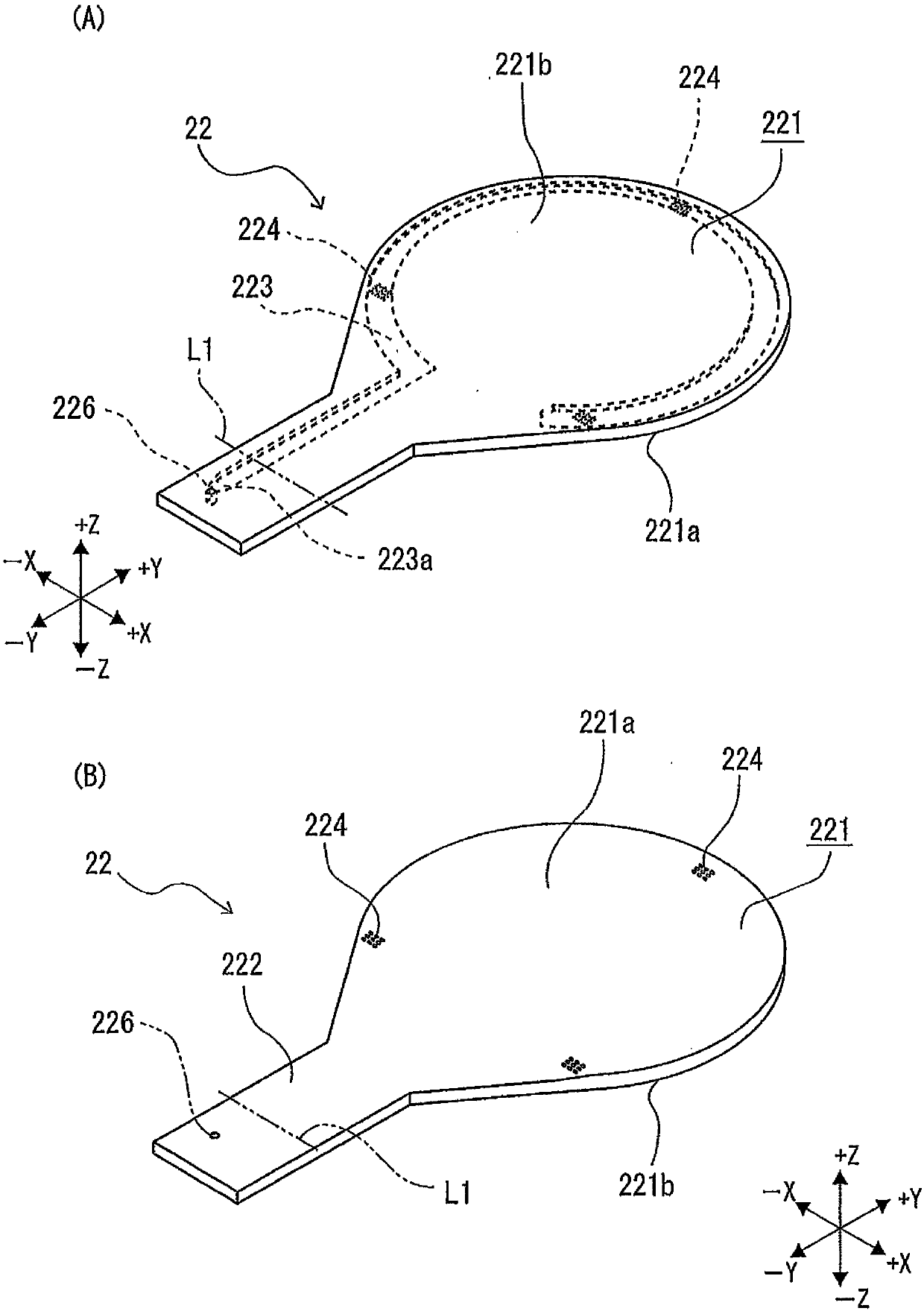

[0026] figure 1 The transfer robot 1 shown is arranged, for example, on a grinding machine not shown, and performs the following operations: carrying out a wafer W stored in a cassette in the shape of a shelf from the cassette, or using a plate-shaped robot arm 2 to place the wafer W on the cassette. W is held and stored in a box, or transported to a holding table T. The plate-shaped robot arm 2 included in the transfer robot 1 has: one surface 211a for suction-holding the wafer W in a non-contact manner; the other surface 221a for suction-holding the wafer; 12.

[0027] figure 1 The illustrated wafer W is, for example, a circular plate-shaped semiconductor wafer. A plurality of devices are formed on the front Wa of the wafer W. For example, a protective tape (not shown) is attached to the front Wa to protect the front Wa. The back surface Wb of the wafer W is a surface to be processed on which grinding or the like is performed.

[0028] figure 1 The robot arm 2 shown has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com