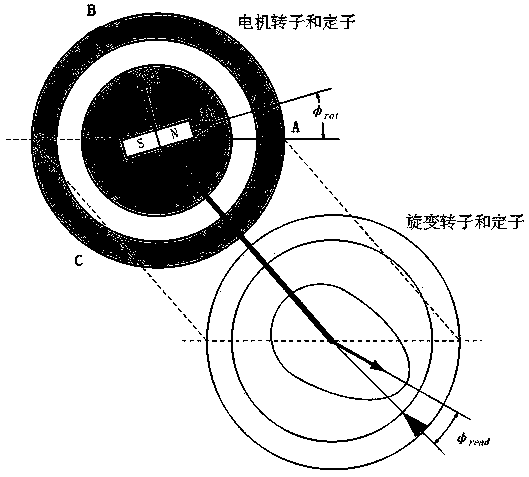

Vehicle permanent magnet synchronous motor rotary transformer zero calibration method and system

A technology of permanent magnet synchronous motor and rotary transformer, which is applied in the direction of instruments, etc., can solve the problems of inaccurate measurement accuracy, inconvenient vehicle measurement, and no continuous rotation, etc., and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

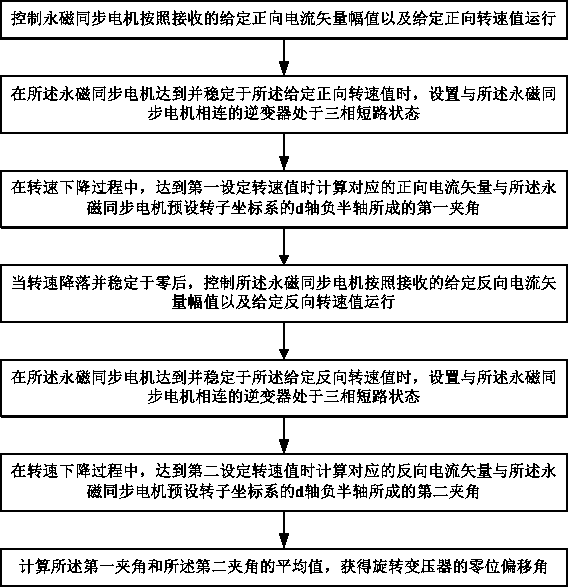

Method used

Image

Examples

Embodiment 1

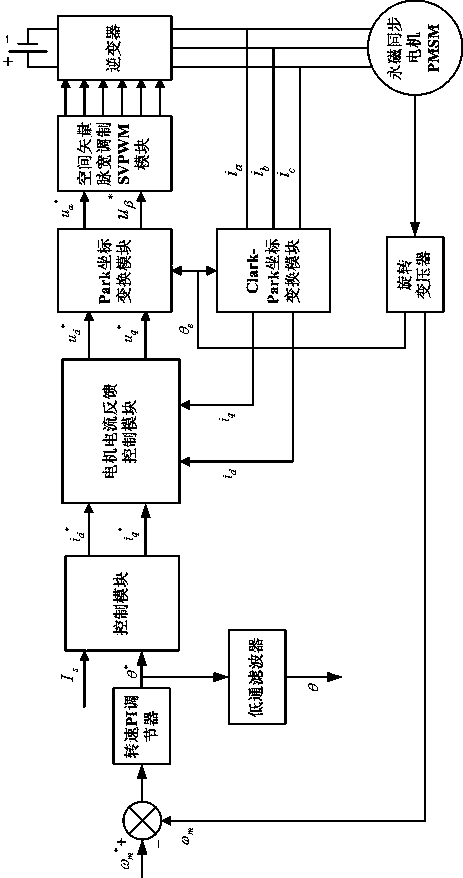

[0072] Corresponding to Embodiment 1 of the present invention, Embodiment 2 of the present invention provides a vehicle-mounted permanent magnet synchronous motor resolver zero calibration system, including:

[0073] The control module is used to control the permanent magnet synchronous motor to operate according to the received given forward current vector amplitude and given forward speed value; when the permanent magnet synchronous motor reaches and stabilizes at the given forward speed value , setting the inverter connected to the permanent magnet synchronous motor to be in a three-phase short-circuit state; Set the first included angle formed by the d-axis negative semi-axis of the rotor coordinate system; it is also used to control the permanent magnet synchronous motor according to the received given reverse current vector amplitude and given Run at a fixed reverse speed value; when the permanent magnet synchronous motor reaches and stabilizes at the given reverse speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com