Preparation method of PCB semi-hole slices

A production method and slicing technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of inferring the drilling conditions of glass fiber cloth and resin on the hole wall, inability to fully reflect the quality information of the hole wall, and affecting the slicing hole problems such as the degree of reduction of the wall, to achieve the effect of tight combination, elimination of protective insulation layer, and high degree of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

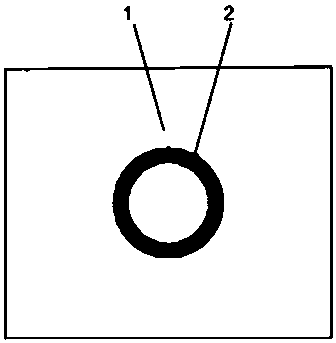

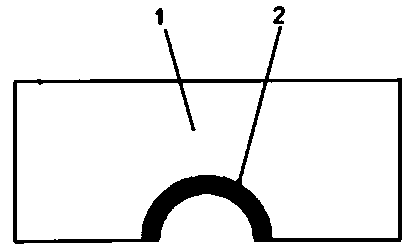

[0038] Such as Figure 1-3 As shown, the present embodiment provides a method for making a PCB half-hole slice, comprising the following steps:

[0039] S1: Add a layer of protective insulation layer 2 on the wall of hole 1 of the PCB template;

[0040] S2: Sampling the target hole with the added protective insulating layer 2, grinding until half of the hole is left, and then polishing;

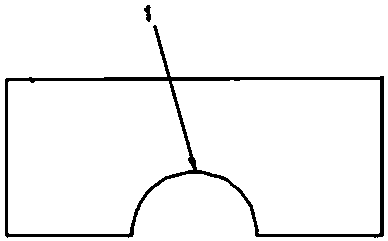

[0041] S3: removing the protective insulation layer 2 on the wall of the polished half-hole section;

[0042] S4: Place the half-hole section after removing the protective insulating layer 2 under a scanning electron microscope and other detection equipment for observation and detection. The results are as follows: Figure 4 shown.

[0043] Adding a layer of protective insulation layer 2 on the hole wall is used to prevent the hole wall from being damaged or adhered to grinding debris during the grinding process of the half-hole slice. After completion, it can be removed under the conditi...

Embodiment 2

[0053] This embodiment provides a method for making a PCB half-hole slice, comprising the following steps:

[0054] S1: Add a layer of protective insulation layer 2 on the wall of hole 1 of the PCB template;

[0055] S2: Sampling the target hole with the added protective insulating layer 2, grinding until half of the hole is left, and then polishing;

[0056] S3: removing the protective insulation layer 2 on the wall of the polished half-hole section;

[0057] S4: Place the half-hole section after removing the protective insulating layer 2 under a scanning electron microscope and other testing equipment for observation and detection to obtain the characteristics or composition information of the half-hole wall, and then infer the entire hole wall condition.

[0058] The protective insulating layer 2 is thermoplastic resin, and the thickness of the protective insulating layer 2 is 2 μm.

[0059] The protective insulation layer 2 in step S3 is softened and eliminated by baking t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com