Dedicated machine for assembly and disassembly of motor rotor assembly, and operating method for dedicated machine

A technology of motor rotor and special machine, applied in the field of electromechanical, can solve the problems of large force on the threaded hole of the rotor, unfavorable repeated disassembly and assembly, difficult operation, etc., and achieves the effect of low labor intensity, strong versatility and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

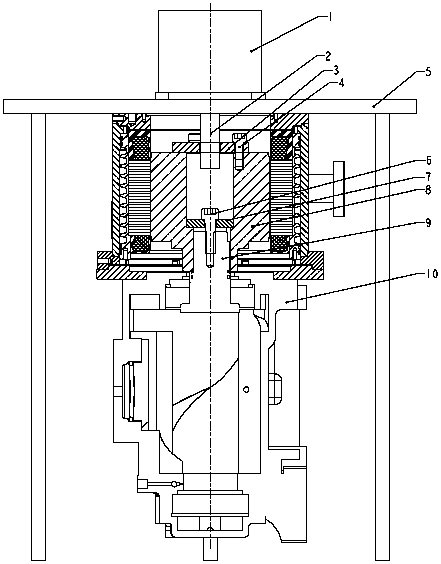

[0030] The following is based on figure 1 The specific embodiment of the present invention is further described:

[0031] see figure 1 , a special machine for installing and dismounting a motor rotor assembly, comprising a cylinder 1, a pressure plate 3, a fixing bolt 4, a bracket 5, a motor rotor assembly 8 to be installed or disassembled, a machine head spindle 9 to be assembled and a main box 10 of the equipment, The support 5 includes a support plate and a plurality of support columns, the support plate is installed on the top of the plurality of support columns, the cylinder 1 is installed on the support plate, and the cylinder 1 is provided with a cylinder push rod 2, so The middle part of the support plate is provided with a hole, the end of the cylinder push rod 2 passes through the hole of the support plate and the end of the cylinder push rod 2 is connected with a pressing plate 3, and the surface of the pressing plate 3 is provided with a plurality of The threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com