Automatic production line cooperatively worked with industrial robot

An automated production line and industrial robot technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems that production depends on robots, and automatic production lines cannot meet production requirements, so as to improve processing efficiency and simplify programming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

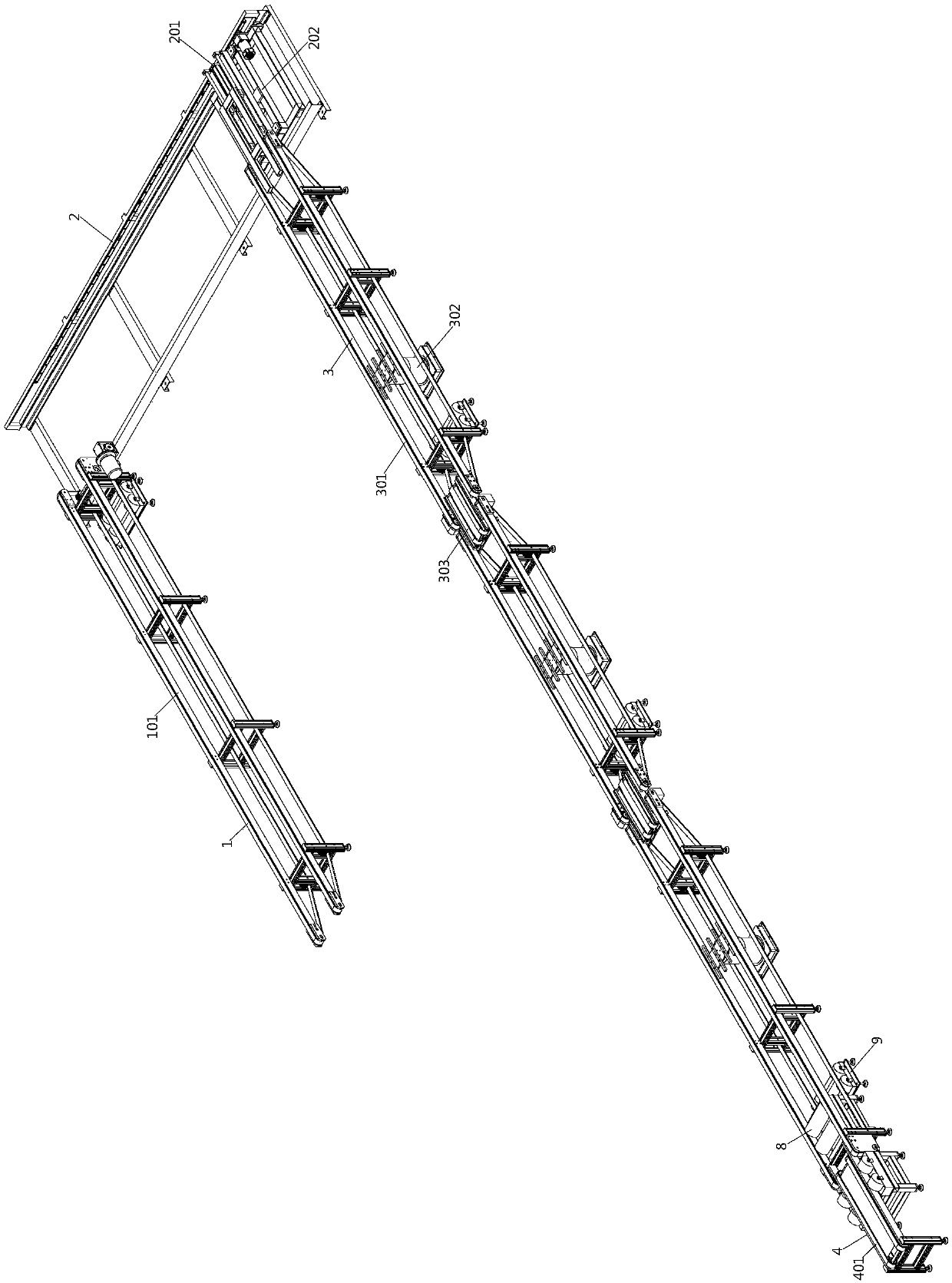

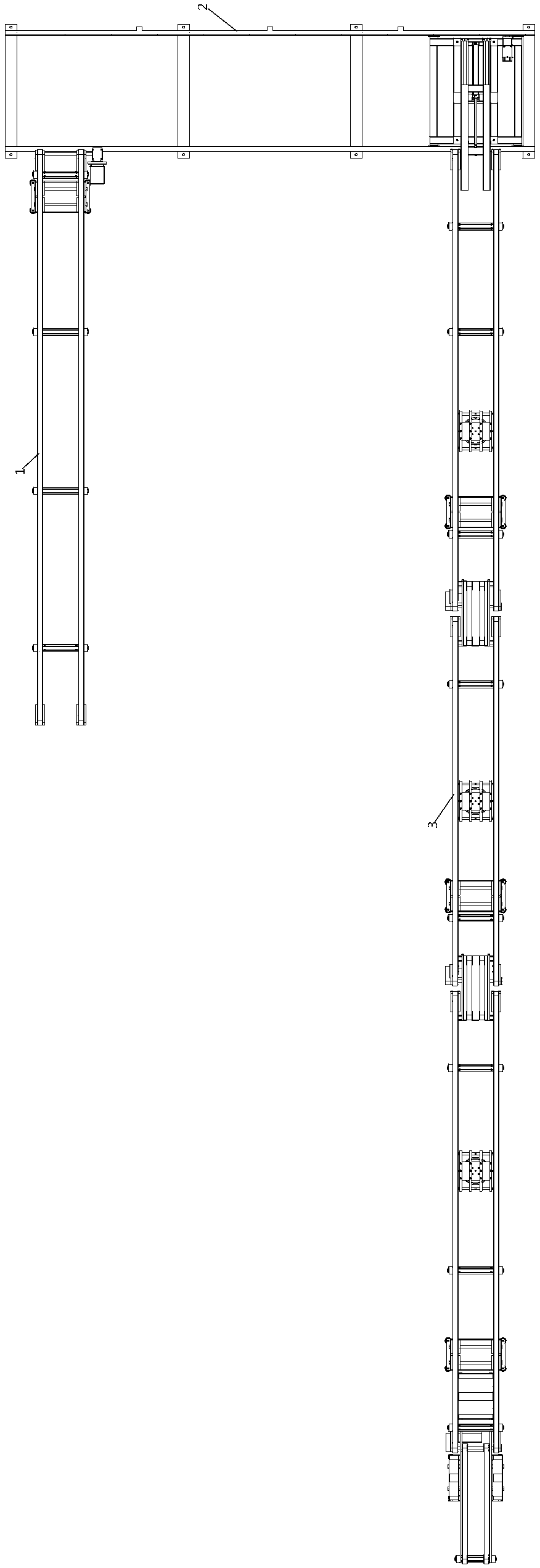

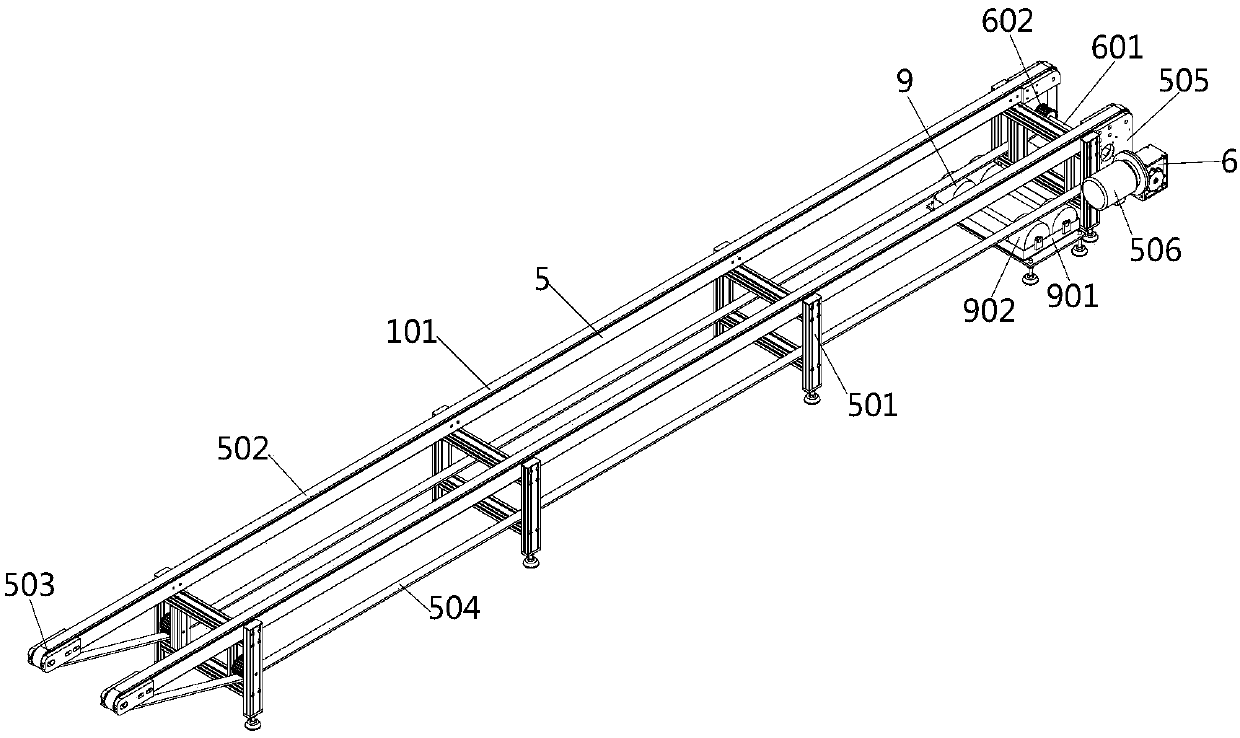

[0032] In order to allow those skilled in the art to understand the present invention more clearly and intuitively, the present invention will be further described below in conjunction with the accompanying drawings.

[0033] The automatic production line that cooperates industrial robot work of the present invention is as figure 1 and 2 As shown, it includes sequentially connected workpiece feeding conveying unit 1, workpiece transfer conveying unit 2, workpiece production and processing conveying unit 3 and finished product conveying unit 4, wherein,

[0034] The workpiece feeding and conveying unit 1 includes a feeding and conveying device 101 to realize horizontal conveying and feeding of workpieces;

[0035] The workpiece transfer conveying unit 2 includes a transfer conveying device 201 and a lift pick-and-discharge device 202 on the transfer conveying device 201 to realize the transfer conveying of the workpiece and the adjustment of the picking height;

[0036]The wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com