Mechanical arm for automatically mounting and demounting hub

A technology of mechanical arms and hubs, applied in the field of mechanical arms for automatic loading and unloading of hubs, can solve the problems of low work efficiency, high cost, time-consuming and laborious, etc., and achieve the effect of being suitable for application and promotion with remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

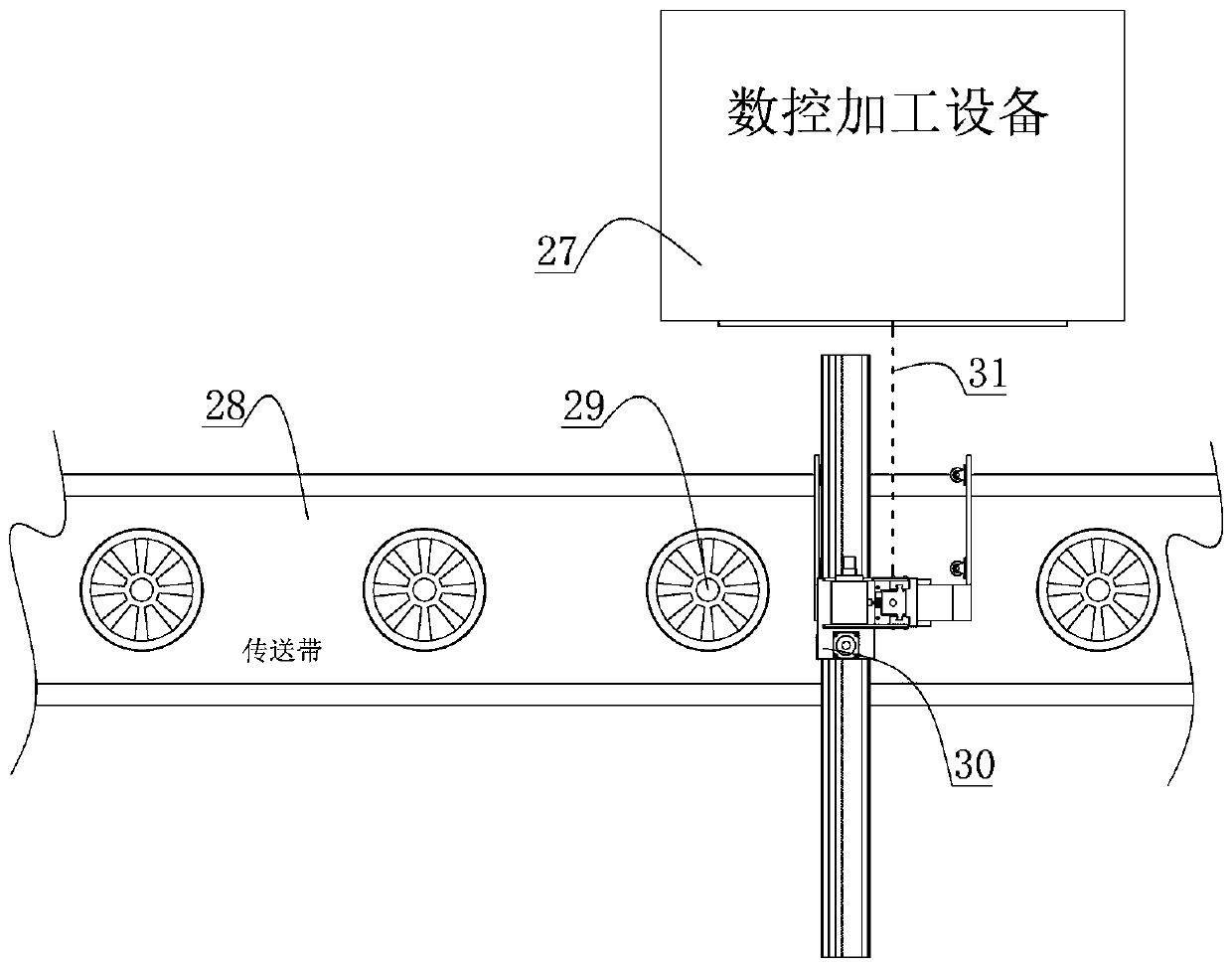

[0022] Such as figure 1 As shown, a schematic diagram of the use place of the mechanical arm for automatically loading and unloading the wheel hub of the present invention is given. Before the mechanical arm of the present invention is installed, the wheel hub 29 transported by the conveyor belt 28 needs to be manually transported to the numerical control processing equipment 27 After the CNC processing equipment 27 finishes processing the wheel hub 29, the worker will remove the wheel hub 29 from the clamping tool and place it on the conveyor belt 28; then move the next wheel hub 29 to be processed, and so on. cycle. It is undoubtedly time-consuming and labor-intensive to rely on manual handling of the wheel hub 29, and the labor cost is relatively high.

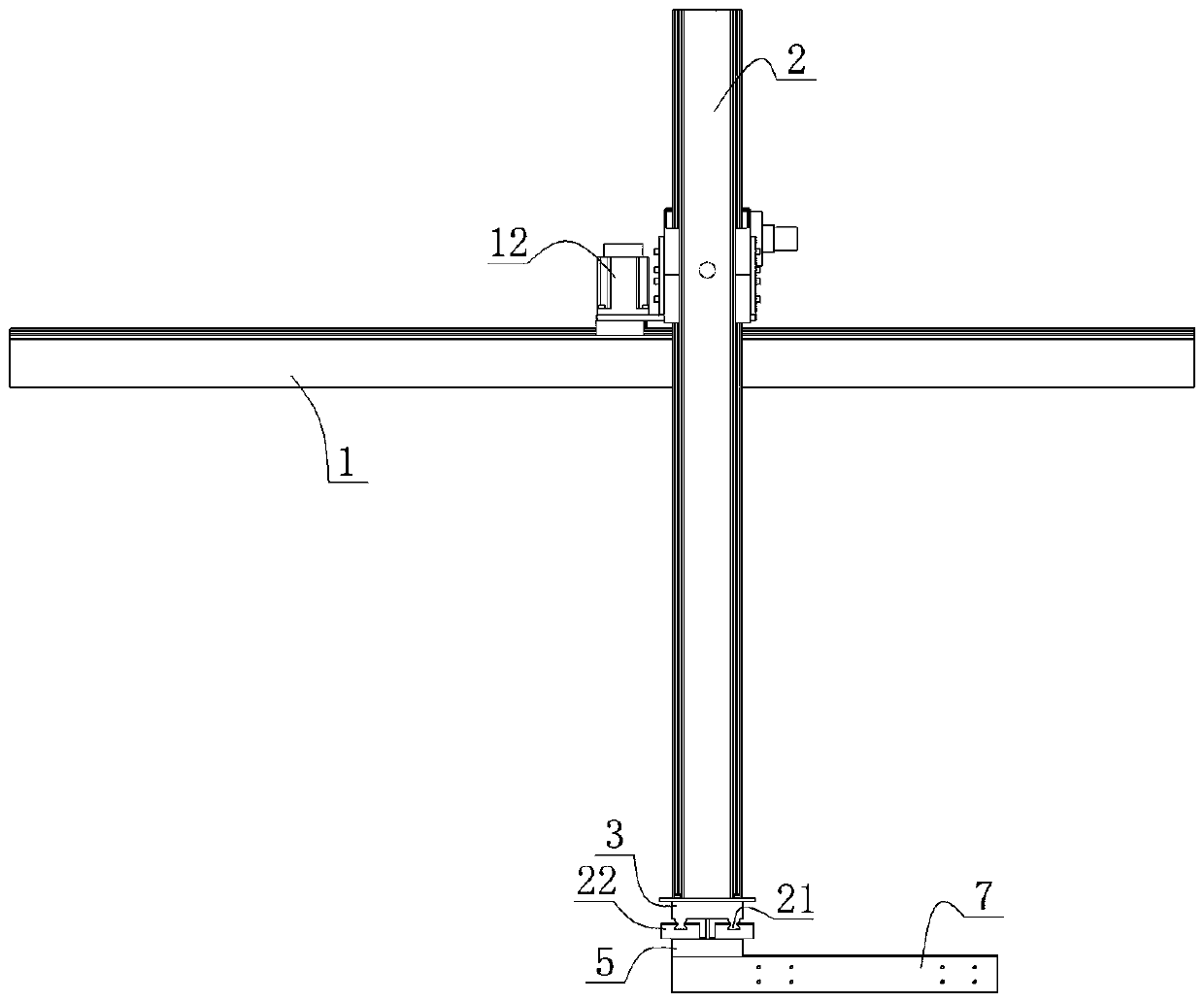

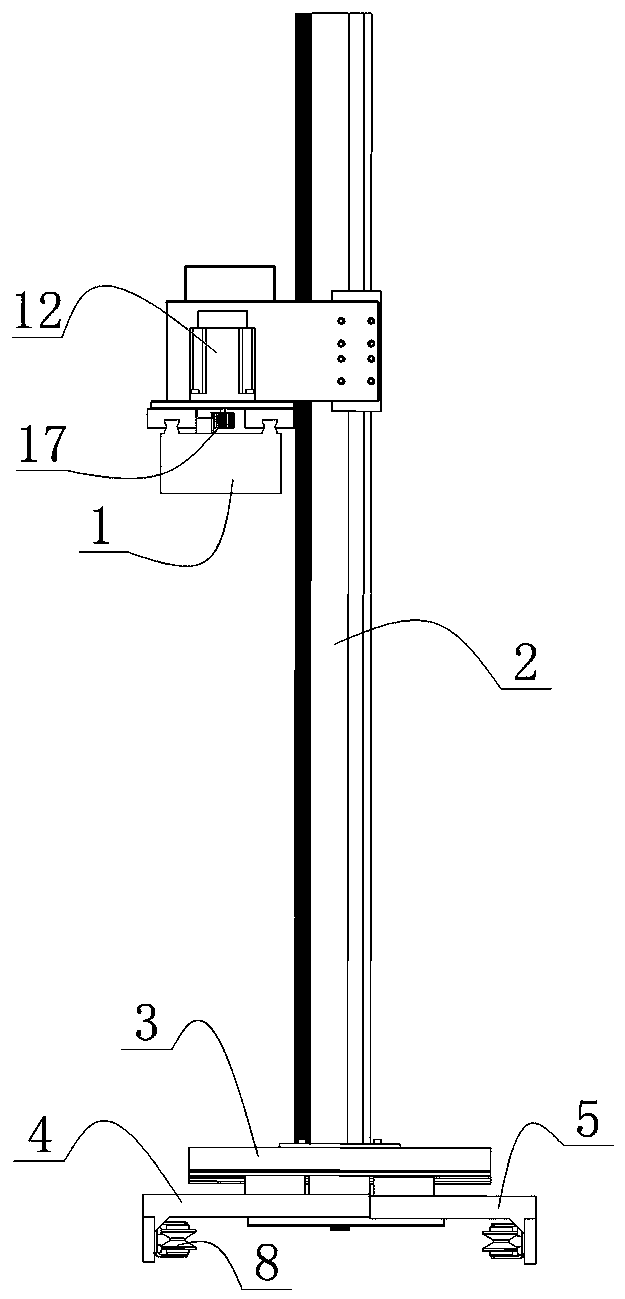

[0023] Such as Figure 2 to Figure 6 As shown, the front view, left view, right view, top view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com