Tungsten needle automatic sharpening equipment

A tungsten needle, automatic technology, used in grinding/polishing equipment, metal processing equipment, grinding machines, etc., to achieve the effect of low risk, high efficiency and uniform wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

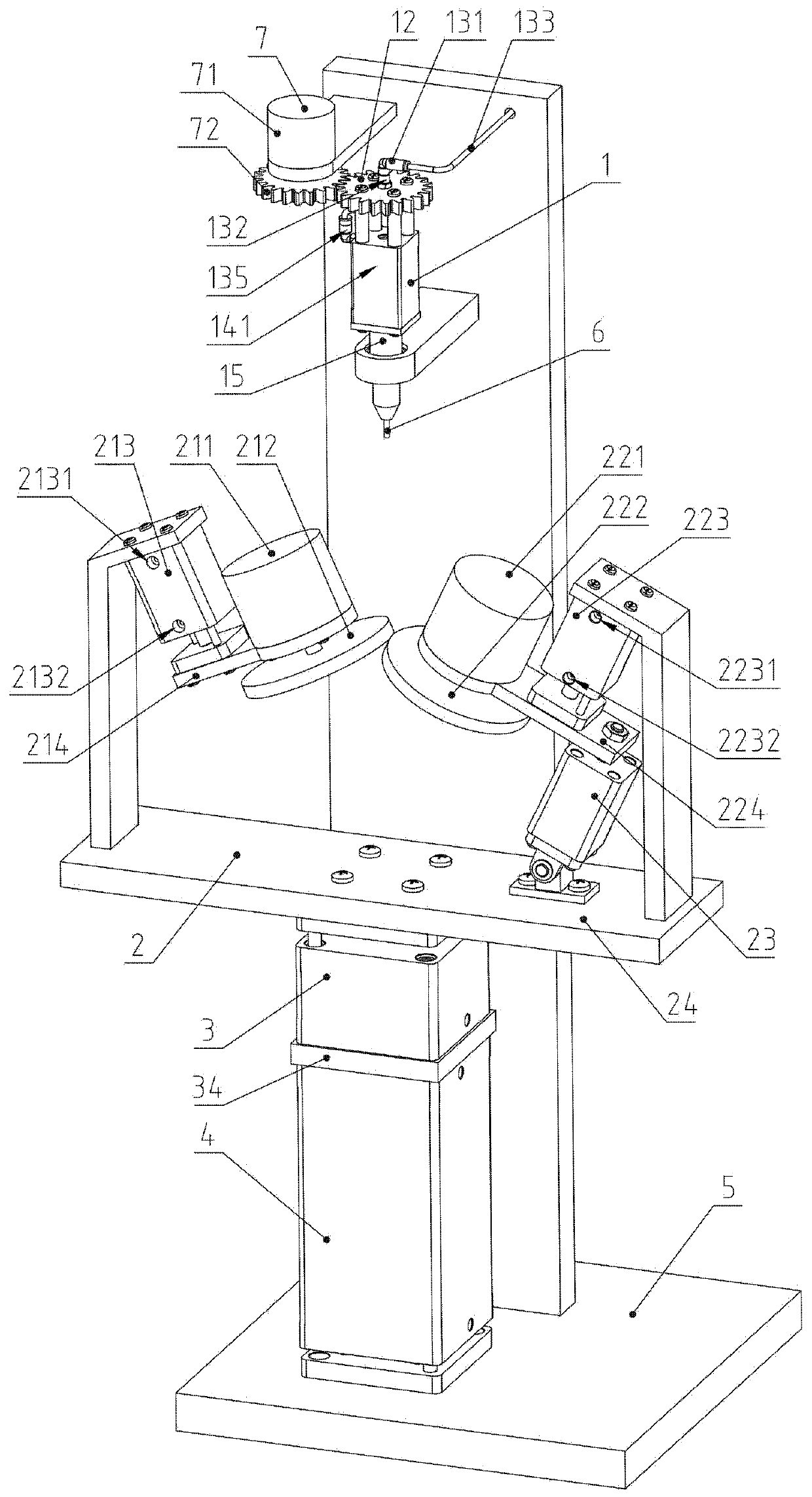

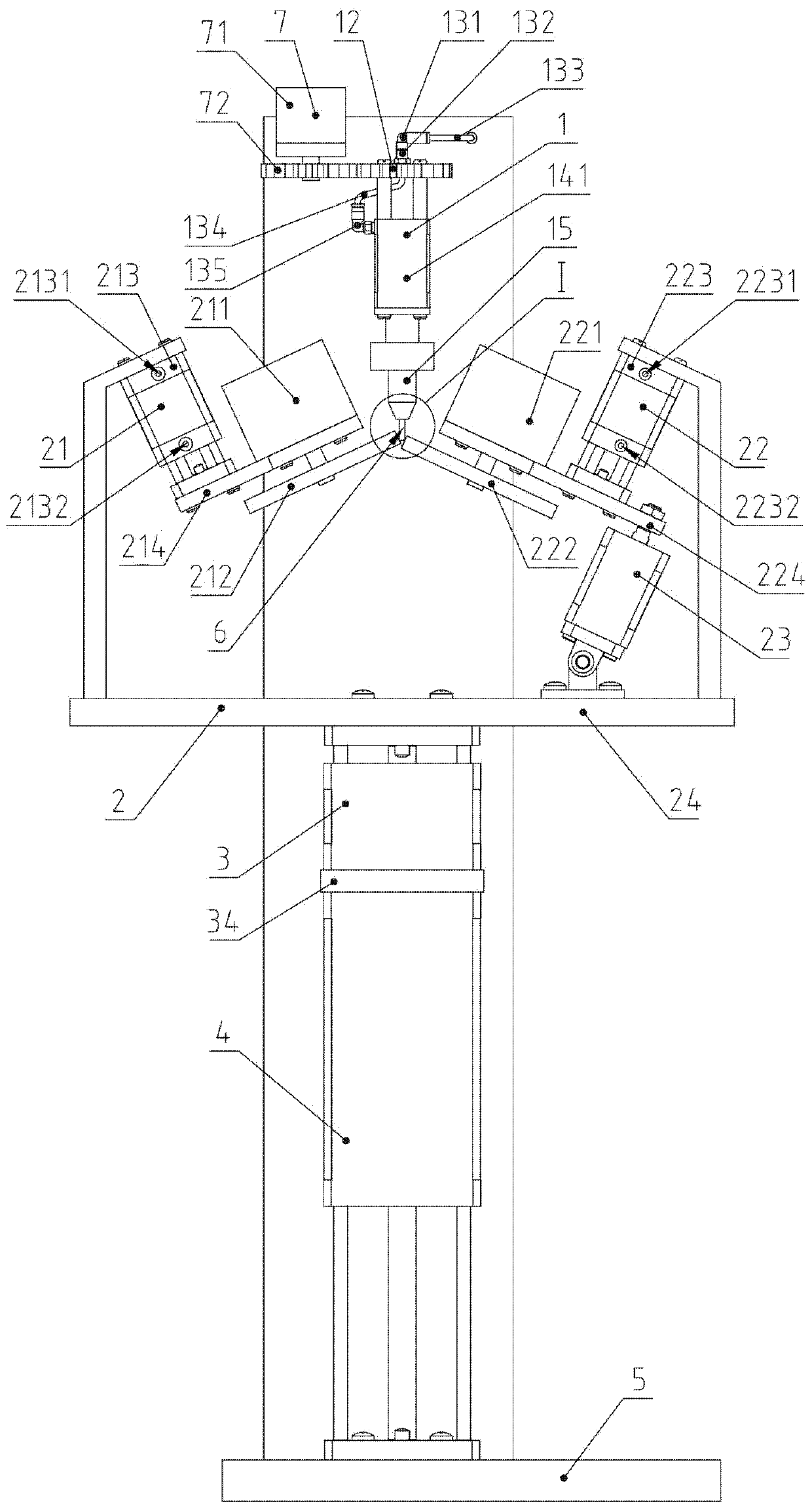

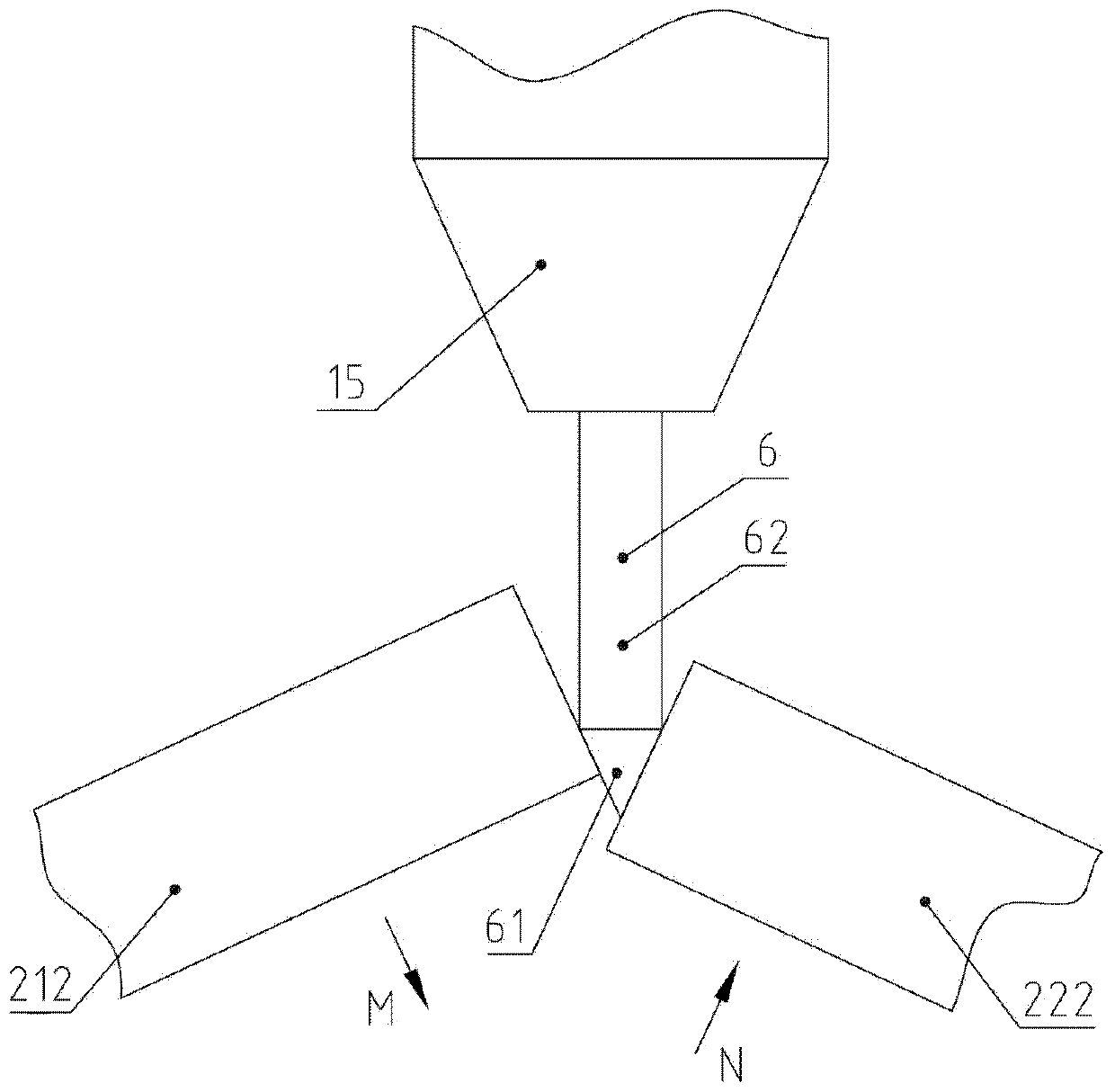

[0039] Example: see Figure 1 to Figure 12 .

[0040] An automatic sharpening device for tungsten needles, comprising a rotary cylinder assembly 1, a grinding wheel assembly 2, a slow lifting cylinder with a guide rod 3, a fast lifting cylinder with a guide rod 4, a frame 5, and a slow rotation drive part 7;

[0041] Slow rotation driving part 7 comprises slow rotation motor 71 and driving gear 72, and the shell flange of slow rotation motor 71 is fixedly connected with frame 5, and the output shaft of driving gear 72 and slow rotation motor 71 is fixedly connected;

[0042] Rotary cylinder assembly 1 comprises passive gear 12, rotary joint, pipeline I 133, flexible pipe II 134; Elbow joint 135, rotary cylinder, sleeve 15 and inner cylinder 17; Including a rotary cylinder body 141 and a rotary cylinder piston rod 142, the rotary cylinder piston rod 142 retracts in the rotary cylinder body 141 in a natural state; the rotary cylinder piston rod 142 is vertically downward; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com