Double-power-flow gear transmission

A transmission, dual power technology, applied in the direction of components with teeth, transmission parts, belts/chains/gears, etc., can solve problems such as difficulty in meeting the grade requirements of the whole vehicle, power interruption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

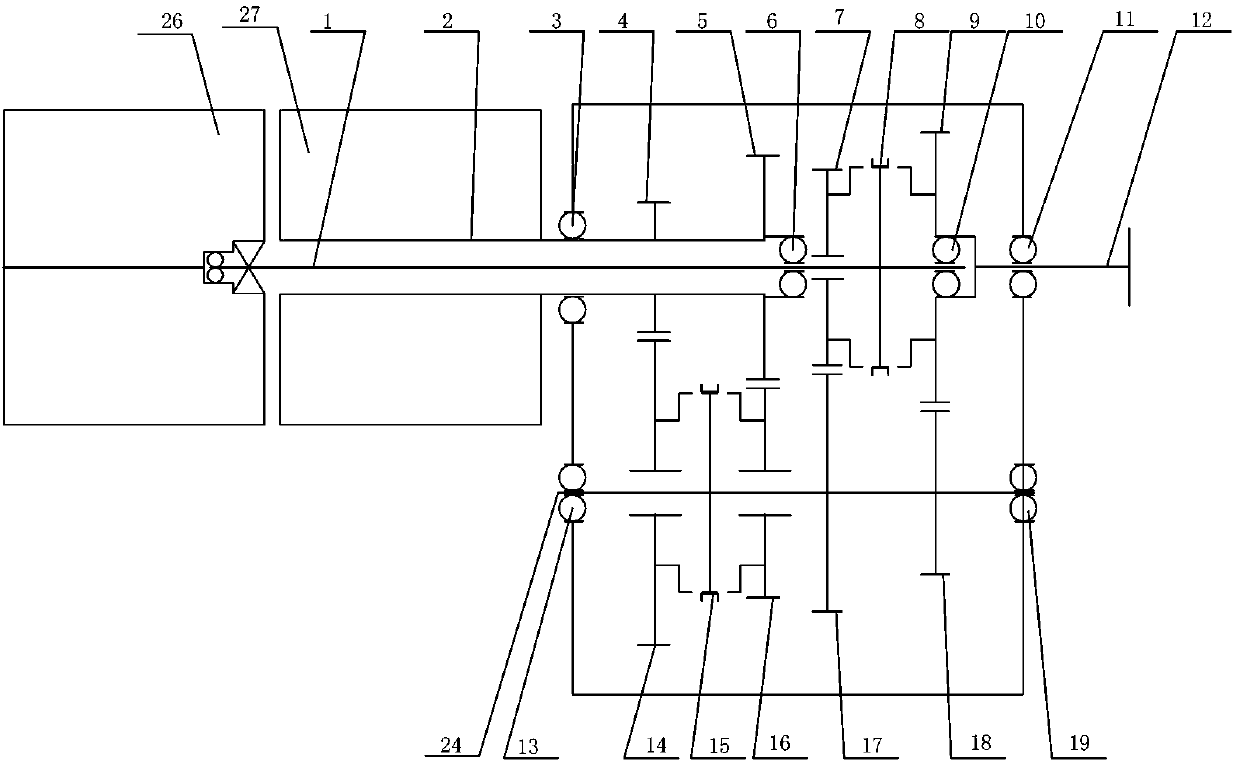

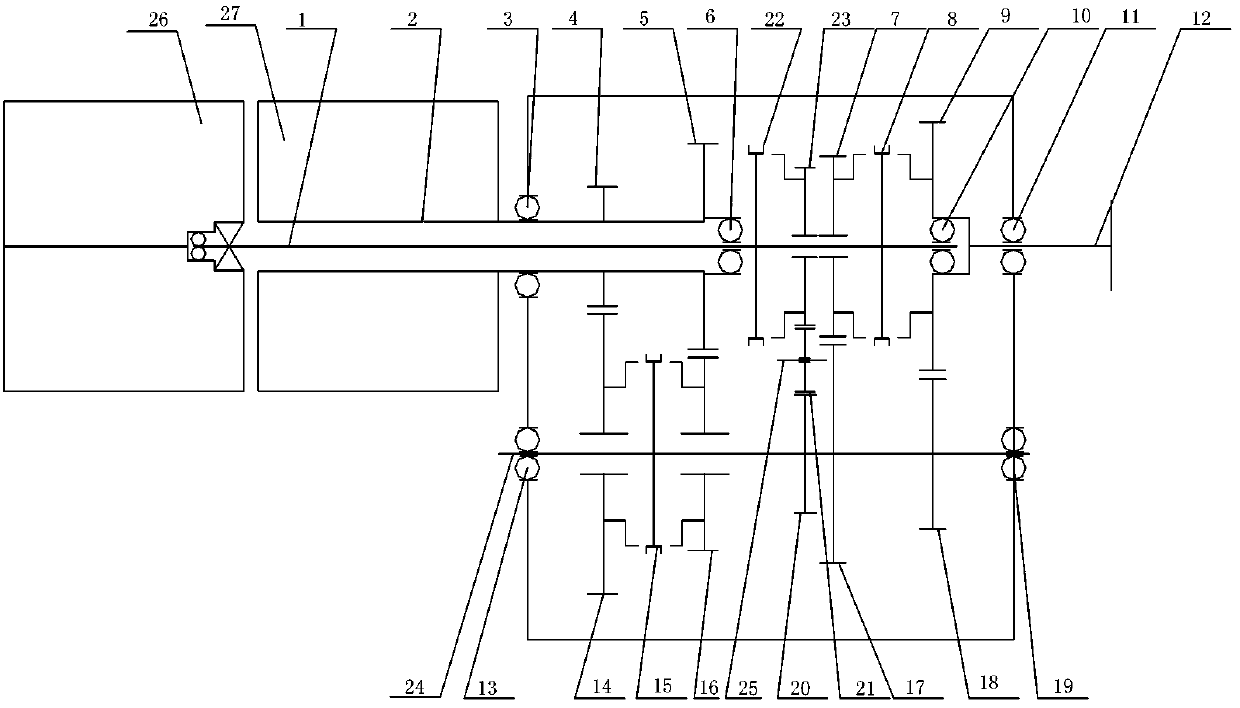

[0023] Referring to the accompanying drawings, specific embodiments of the present invention will be described in detail.

[0024] see figure 1, an embodiment of a dual-power flow transmission with gears, a dual-power flow transmission with gears, including a transmission housing, the hollow shaft front bearing 3 in the transmission housing supports the first input shaft 2, and the first input shaft 2 One end protrudes from the transmission casing, and the protruding end is used to connect with the second power device 27, and the first power device 26 can be a motor. The shaft section of the first input shaft 2 is fixedly connected to the first gear 4 of the hollow shaft and the third gear 5 of the hollow shaft in sequence. Preferably, the first gear 4 of the hollow shaft and the third gear 5 of the hollow shaft are integrally formed respectively. On the first input shaft 2, if the one-piece structure is adopted, there is no need to cut keyways or splines on the first input s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com