Periodic blowdown expansion container with self-water sealing function, drainage system and method

A technology of regular sewage discharge and container expansion, which is applied in the field of power plants, can solve the problems affecting the reliability and user experience of heat exchangers, the formation of dirt on the surface of heat exchangers, and the impact on the stability of unit operation, so as to save equipment, prevent backflow, and reduce The effect of flushing destructive power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

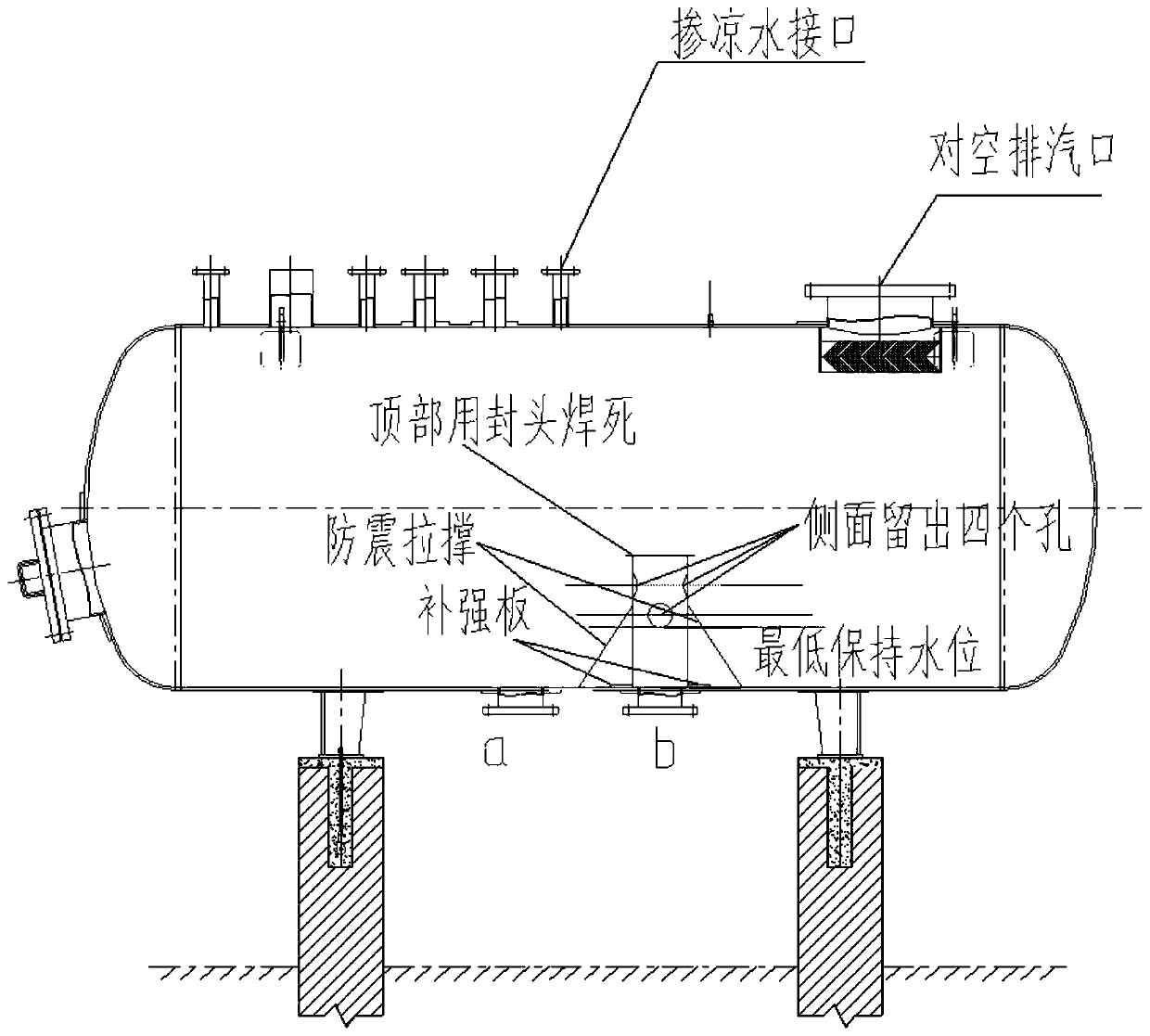

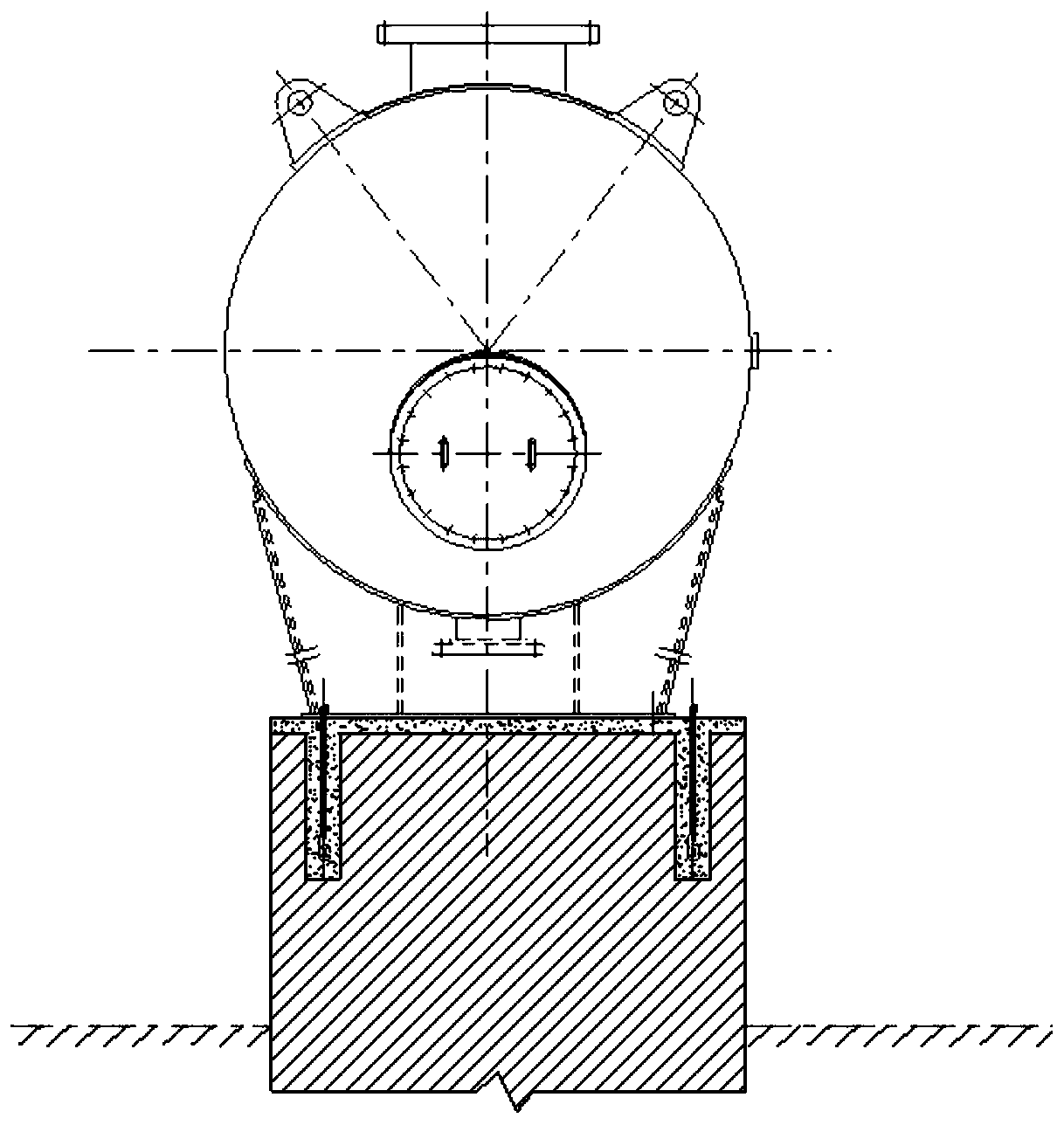

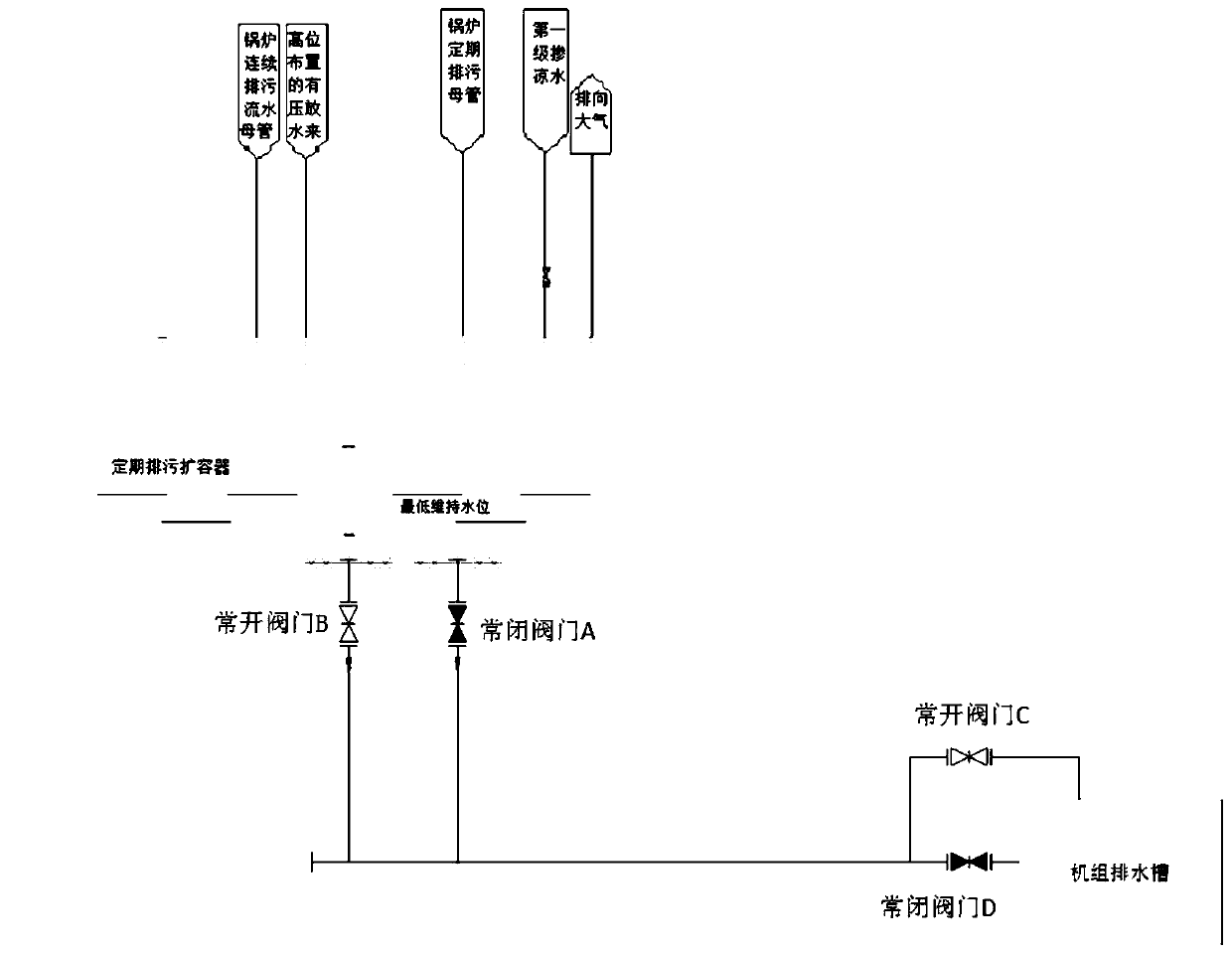

[0050] The invention discloses a regular blowdown expansion container with self-water sealing function, such as figure 1 and figure 2 As shown, it includes: the body of the regular sewage expansion container, two sewage outlets are arranged at the bottom of the regular sewage expansion container body, and a diversion pipe connected to one of the sewage outlets is arranged inside the regular sewage expansion container body. The minimum maintenance water level of the blowdown expansion vessel;

[0051] Diversion holes are set on the wall of the diversion pipe above the minimum maintenance water level of the regular sewage expansion vessel, and the position of the diversion hole can ensure that the water stored in the regular sewage expansion vessel is always kept at the lowest water level.

[0052] The opening at the top of the guide tube is facing upwards, and the top of the guide tube is sealed, such as image 3 As shown, a number of diversion holes are opened on the side w...

Embodiment 2

[0065] In this embodiment, the opening of the guide pipe section faces downwards through the form of an elbow, such as Figure 4 As shown, there is no need to open diversion holes on the standpipe at this time, and vent holes are opened on the top of the elbow. Water can enter the diversion pipe through the inverted elbow. At this time, the lowest liquid level is at the elbow, and it can also avoid entering The fixed row of water flows directly into the diversion pipe section.

[0066] The rest of the structure is the same as that of the first embodiment, and will not be repeated here.

Embodiment 3

[0068] In this embodiment, the diversion pipe section is connected to the upper part of the expander to play a role of reinforcement, such as Figure 5 As shown, at this time, the diversion hole is only opened above the minimum maintenance water level, and the area that can be used to open the diversion hole also increases.

[0069] The rest of the structure is the same as that of the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com