Roller bed type ceramic drying kiln bar scraping device

A technology of drying kiln and roller table, which is applied in the direction of furnace type, descaling device, furnace, etc. It can solve the problems of low efficiency, incomplete removal of rod nails, cracking, etc., and achieve the effect of efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

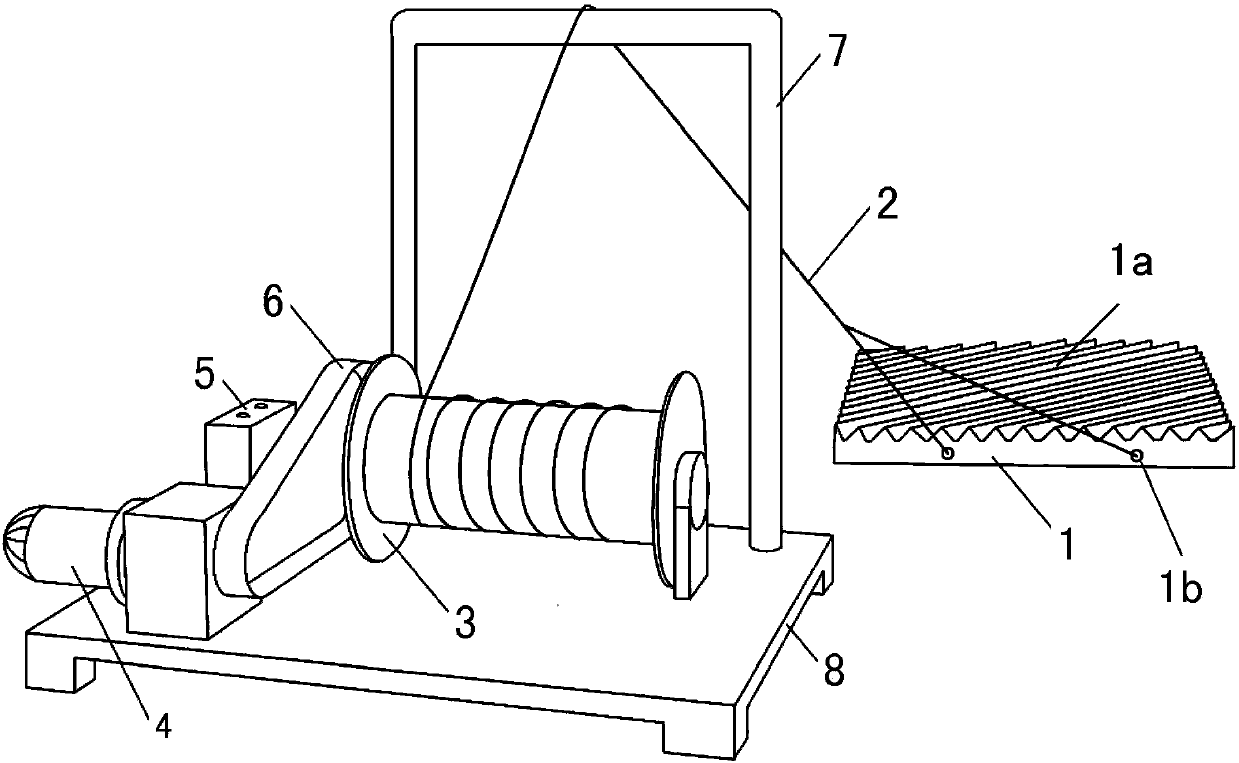

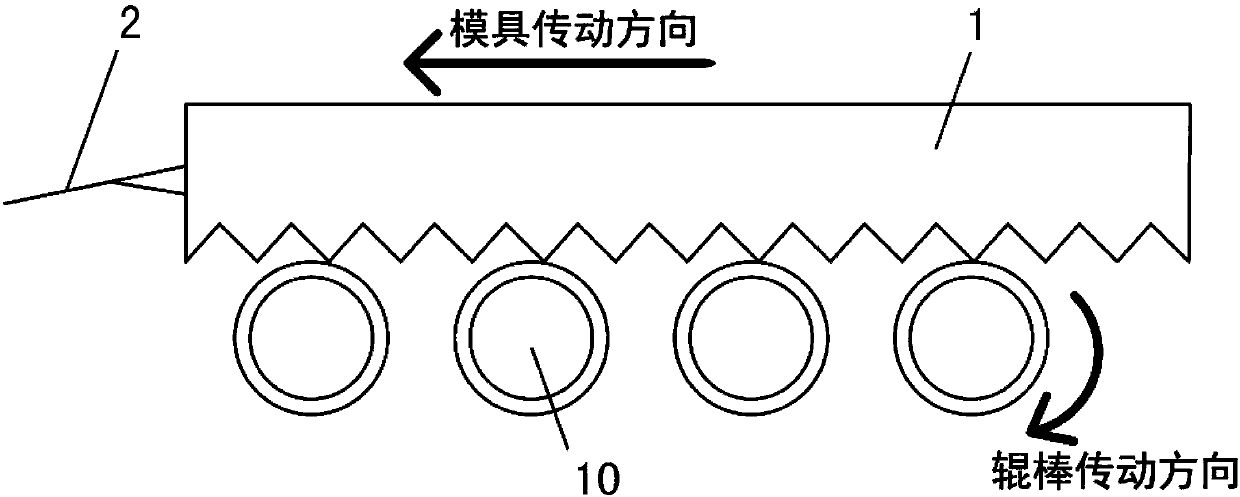

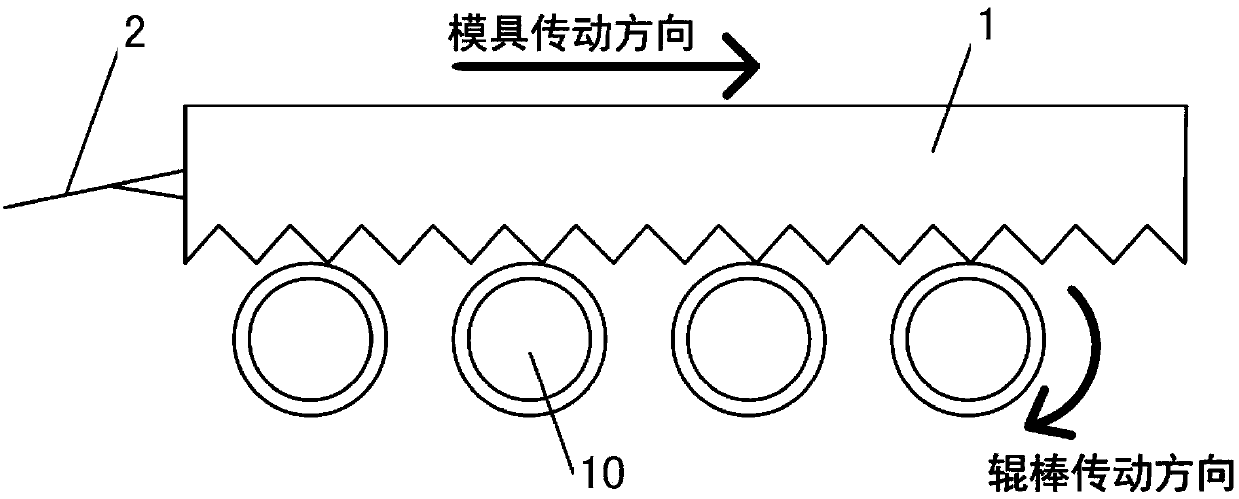

[0040] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The same reference numerals are assigned to the same or corresponding components in the respective drawings.

[0041] In order to overcome the various deficiencies in the prior art when removing the nails on the rollers of the drying kiln, the invention provides a roller table type ceramic drying kiln rod scraper, which has: a scraper mold, the scraper The mold is provided with a connection hole, and one surface of the scraper mold has saw teeth; a steel wire rope; a main body platform, on which a roller and a fixed rod are arranged; the steel wire rope is erected on the fixed rod and one end passes through the connecting rod. The hole is connected to the scraping rod mold, and the other end is wound on the roller; the rotation of the roller makes the steel wire rope pull the scraping rod mold to scrape the rod. Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com