Intelligent factory management platform and method

A factory management and intelligent technology, applied in data processing applications, instruments, manufacturing computing systems, etc., can solve problems such as unfavorable intelligent factory data sharing, and achieve the goal of promoting vertical and horizontal integration, realizing intelligent management, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

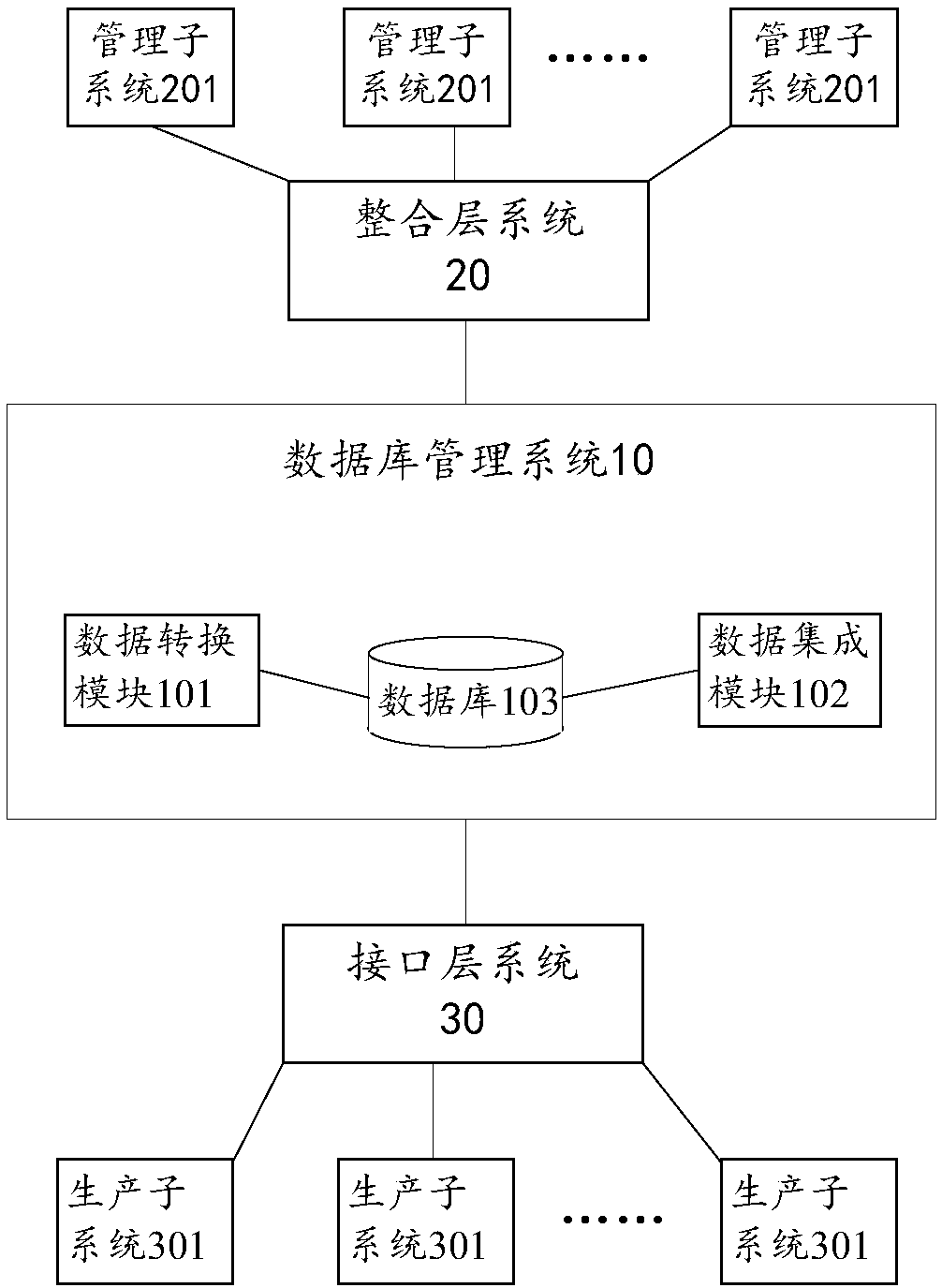

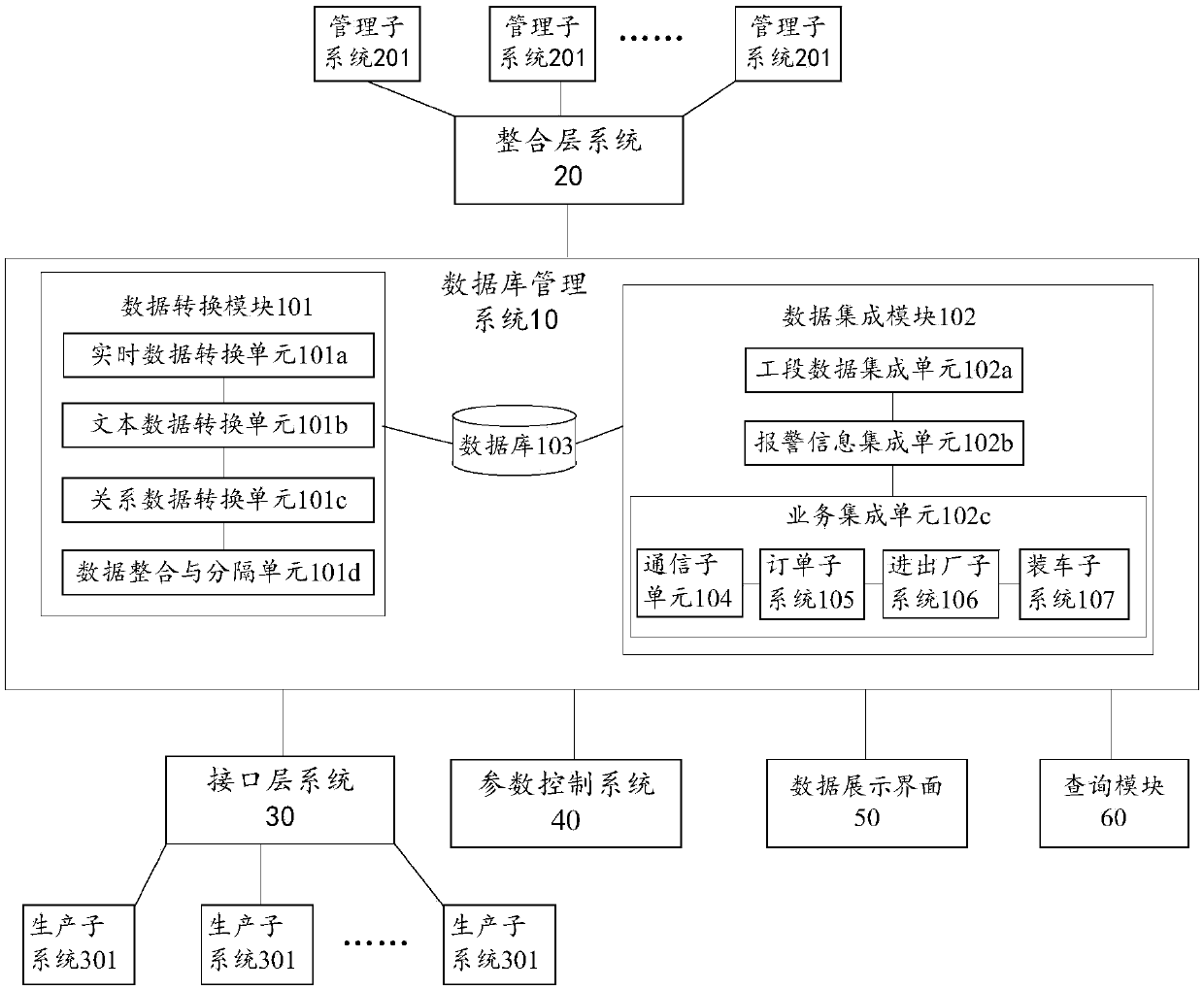

[0028] An embodiment of the present invention provides a smart factory management platform, and a server of the smart factory management platform can be set in a management department of the smart factory for intelligent management of the smart factory. like figure 1 A schematic structural diagram of an intelligent factory management platform is shown, including: a database management system 10 , an integration layer system 20 and an interface layer system 30 , wherein both the integration layer system 20 and the interface layer system 30 are communicatively connected to the database management system 10 .

[0029] During specific implementation, the integration layer system 20 communicates with the management subsystem 201 of the smart factory, and is used to receive the data information uploaded by each management subsystem, analyze and process the data information, and convert each management subsystem's Data information is stored in a specified area in the database managem...

Embodiment 2

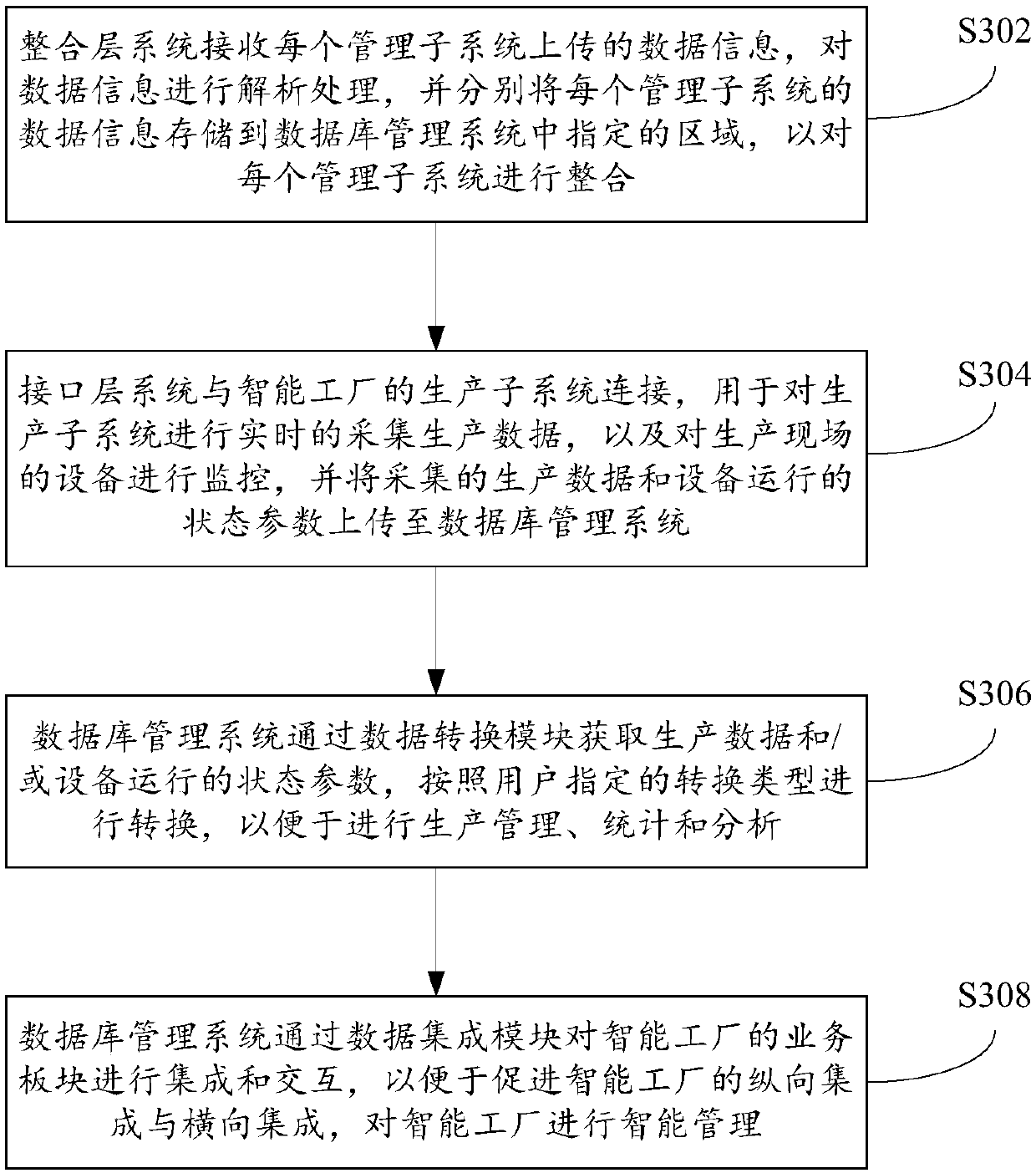

[0059] In order to facilitate the understanding of the above-mentioned smart factory management platform, on the basis of the above-mentioned embodiments, the embodiment of the present invention also provides a smart factory management method, which is applied to the smart factory management platform described in the above-mentioned embodiments, and performs a smart factory Intelligent management, such as image 3 A flow chart of a smart factory management method is shown, the method includes the following steps:

[0060] Step S302, the integration layer system receives the data information uploaded by each management subsystem, analyzes and processes the data information, and stores the data information of each management subsystem in the designated area in the database management system, so that each management subsystem Subsystems are integrated;

[0061] Among them, the management subsystem includes one or more of the following subsystems: financial management subsystem, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com