Wireless communication system and method for monitoring state of hobbing cutter of shield tunneling machine

A wireless communication system and wireless communication technology, which is applied in the field of wireless communication system for shield machine hob state monitoring, can solve the problems of continuous measurement, non-reusable use, and single detection function, so as to reduce design difficulty and design cost , Reduce the difficulty of work, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

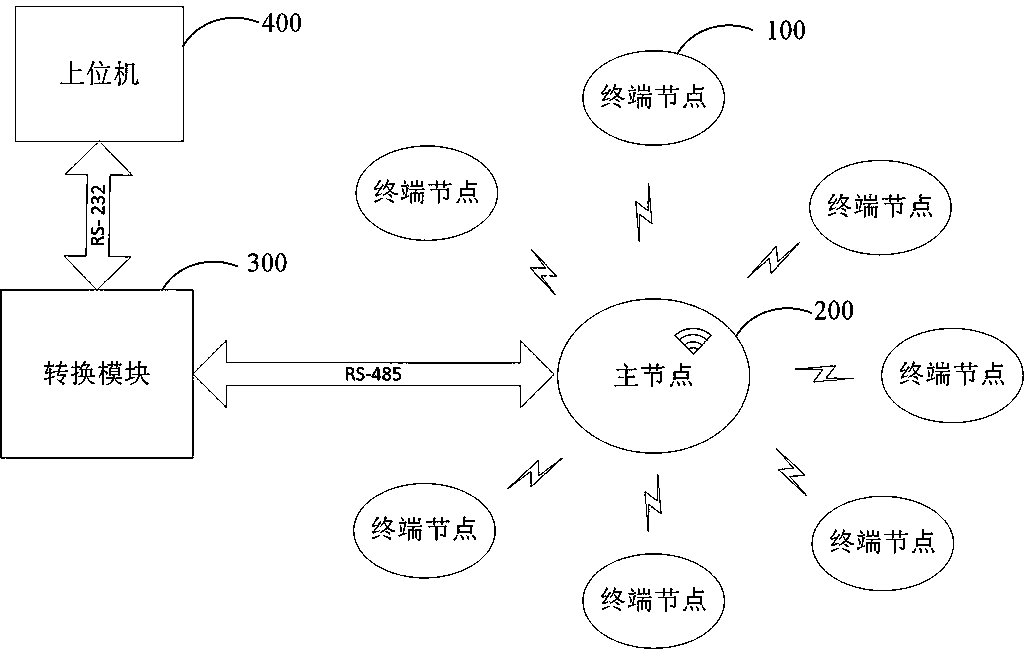

[0063] Embodiment 1: as figure 1 As shown, a wireless communication system applied to the condition monitoring of shield machine hobs includes a terminal node 100, a master node 200, a conversion module 300 and a host computer 400; the terminal node 100 is wirelessly connected to the master node 200, and the The master node 200 is connected to the conversion module 300 through the RS485 bus, and the conversion module 300 is connected to the upper computer 400 through the RS232 bus;

[0064] The terminal node 100 is used to receive, collect and process sensor signals, the processed sensor signals are digital signals, and transmit the digital signals to the master node 200 through wireless;

[0065] The master node 200 is configured to receive a digital signal transmitted from the terminal node 100, and send a control command and data transmission after processing the digital signal;

[0066] The conversion module 300 is used to convert the RS485 bus data signal sent by the mas...

Embodiment 2

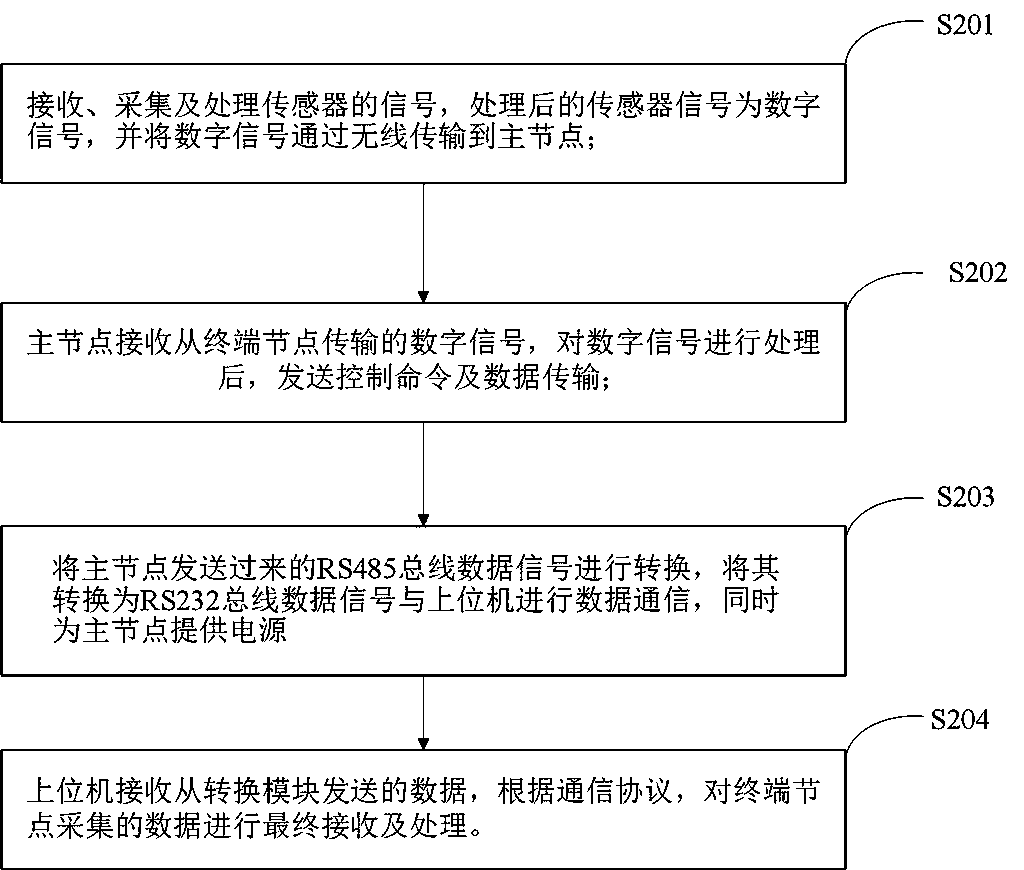

[0068] Embodiment 2: as figure 2 As shown, a wireless communication method applied to the state monitoring of the hob of the shield machine based on a wireless communication system applied to the state monitoring of the hob of the shield machine includes the following steps:

[0069] Step S201: receiving, collecting and processing the sensor signal, the processed sensor signal is a digital signal, and the digital signal is transmitted to the master node through wireless;

[0070] Step S202: the master node receives the digital signal transmitted from the terminal node, processes the digital signal, and sends a control command and data transmission;

[0071] Step S203: Convert the RS485 bus data signal sent by the master node into an RS232 bus data signal for data communication with the host computer, and at the same time provide power for the master node;

[0072] Step S204: The upper computer receives the data sent from the conversion module, and finally receives and proces...

Embodiment 3

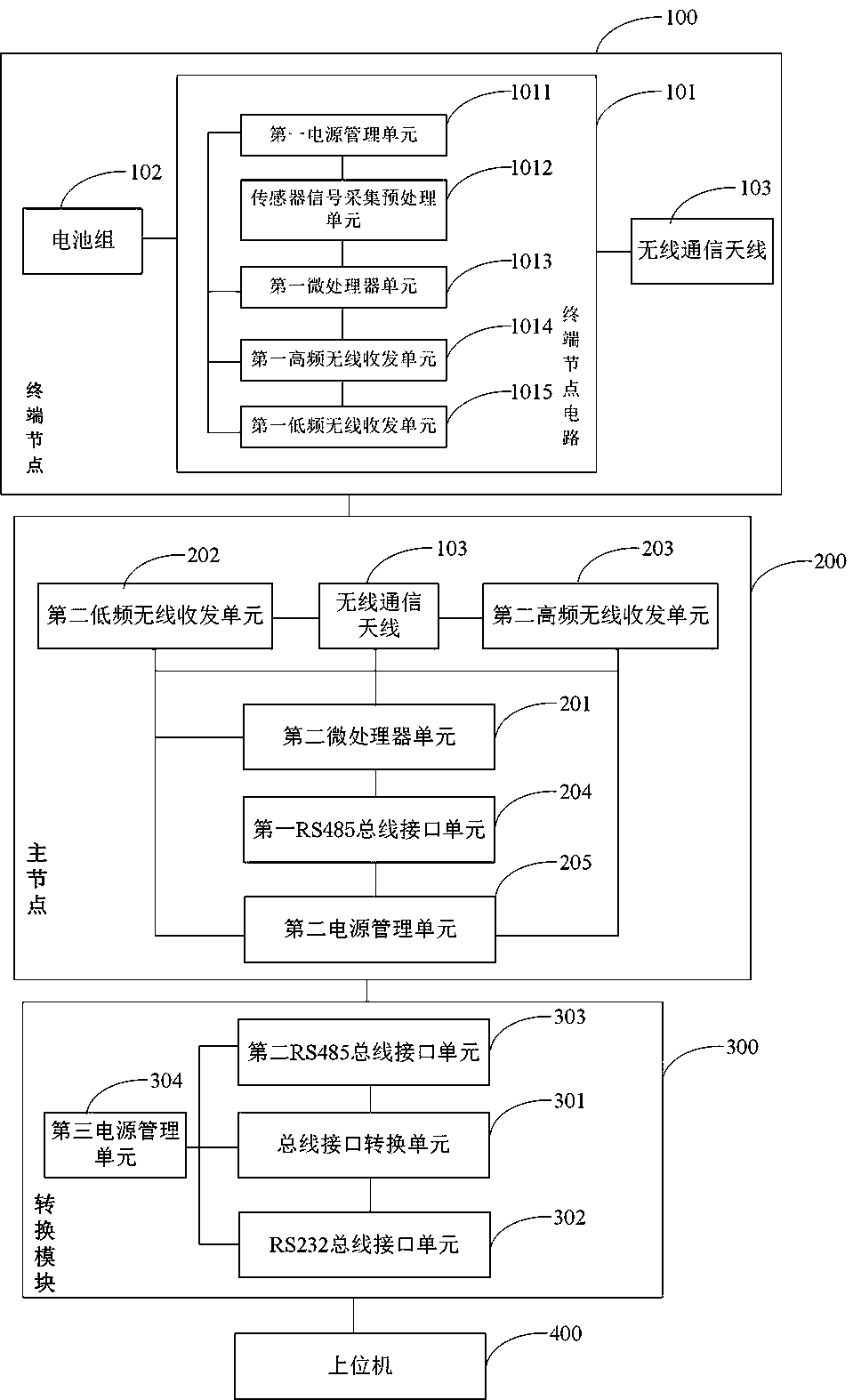

[0073] Embodiment 3: as image 3 As shown, another wireless communication system applied to the state monitoring of the hob of the shield machine includes a terminal node 100, a master node 200, a conversion module 300 and a host computer 400;

[0074] The terminal node 100 is used to receive, collect and process sensor signals, the processed sensor signal is a digital signal, and the digital signal is transmitted to the main node 200 through wireless; the terminal node 100 and the main node 200 form a star Network topology; each terminal node 100 includes a terminal node circuit 101, a battery pack 102 and a wireless communication antenna 103;

[0075] The terminal node circuit 101 also includes a first power management unit 1011, a sensor signal acquisition preprocessing unit 1012, a first microprocessor unit 1013, a first high frequency wireless transceiver unit 1014 and a first low frequency wireless transceiver unit 1015;

[0076] The first power management unit 1011 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com