Heating device, heating method and shaft assembly method

A heating device and heating film technology, applied in the direction of induction heating device, electric heating device, induction heating, etc., can solve the problems of potential safety hazards, high assembly cost, and damage to shafting assembly quality, so as to reduce personal safety hazards and reduce assembly costs. Equipment cost, effect of eliminating noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

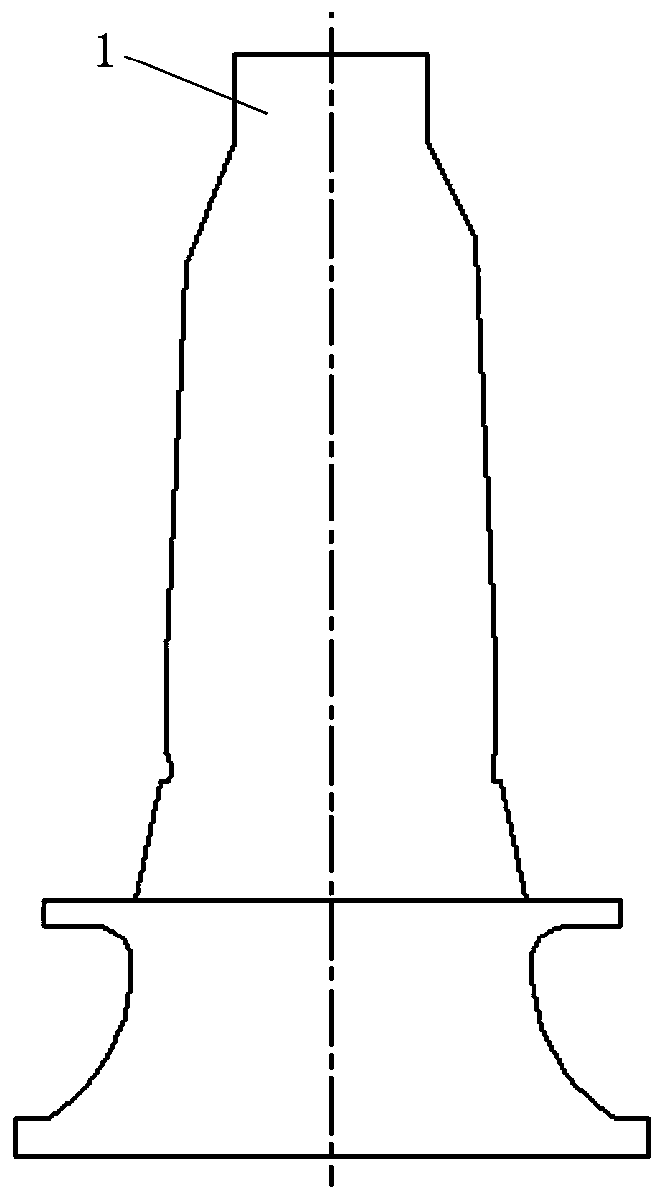

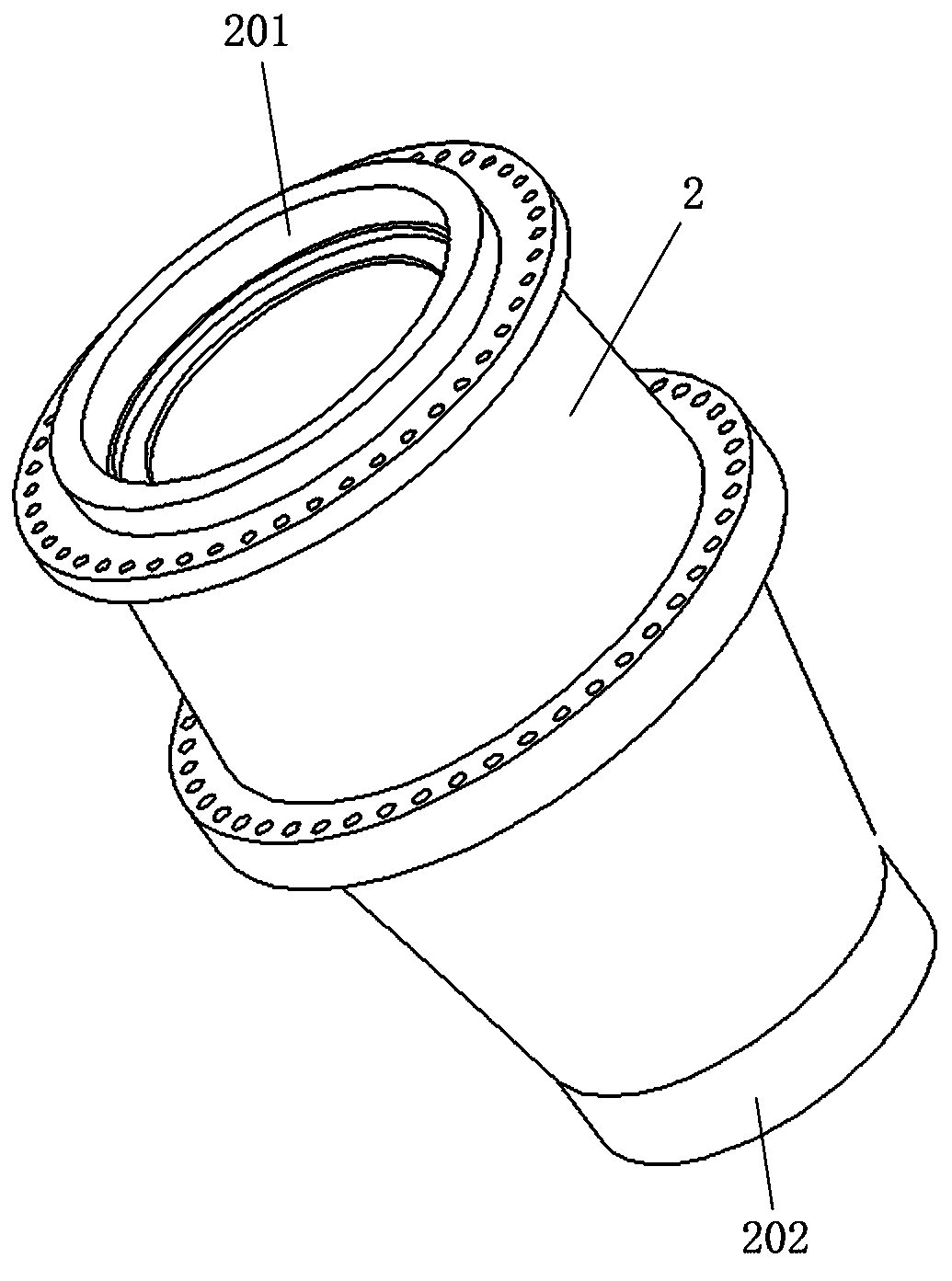

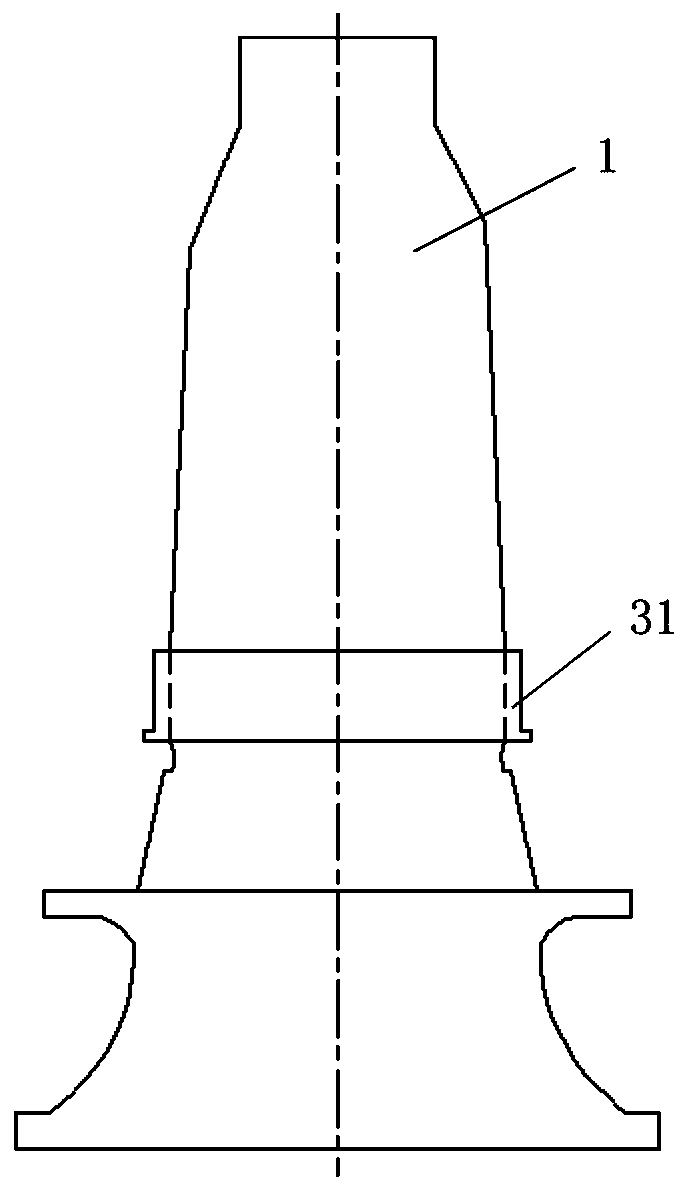

[0068] In order to solve various problems existing in the prior art, the inventors of the present invention propose a A new type of heating device, heating method and shafting assembly method for large-scale, large-mass, variable-diameter, non-equal-section components. Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to fully convey the technical concept of the present invention to those skilled in the art.

[0069] In order to avoid the problem that the inner ring of the bearing and the outer ring of the bearing collide with each other and cause damage to the bearing during the process of fitting the rotating shaft to the main shaft of the stator, the embodiment of the present invention still adopts the rear bearing between the main shaft of the stator and the rotating shaft during the fitting process. "One whole" thinking.

[0070] In the case of the rear bearing as a whole, in order to ensure the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com