Efficient permanent magnet motor direct-drive screw pump oil mining and transporting equipment

A permanent magnet motor and screw pump technology, applied in mechanical equipment, drilling equipment, pumps, etc., can solve the problems of high lift, large displacement units, poor axial bearing capacity of units, short service life, etc., and achieve infinite Safety risk, reliable sealing, effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

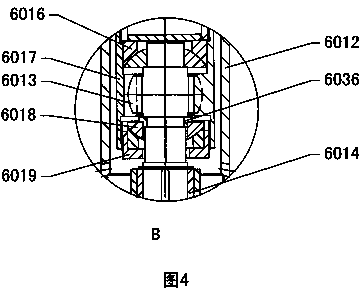

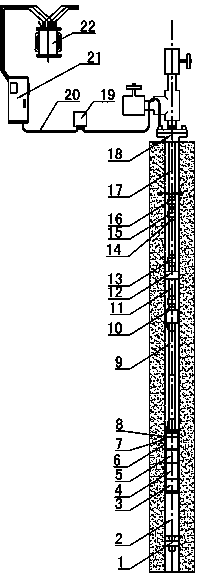

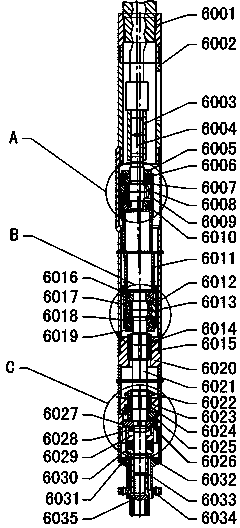

[0049] Figure 1-7 It is the best embodiment of the present invention, below in conjunction with attached Figure 1-7 The present invention will be further described.

[0050] Refer to attached figure 1 : A high-efficiency permanent magnet motor direct drive screw pump oil production and transportation equipment, including a screw pump assembly 9, the bottom of the screw pump assembly 9 is sequentially installed with a bottom centralizer 1, a high-efficiency permanent magnet submersible motor unit, a series bearing group and The two-way thrust universal coupling 6, the upper part of the screw pump assembly 9 is connected to the oil delivery pipe 17, a plurality of valve assemblies are installed in the oil delivery pipe 17, and the upper end of the oil delivery pipe 17 is connected to the ground device. The surface device includes a special wellhead device 18 , a wellhead junction box 19 , a second armored cable 20 , a control cabinet 21 and a wellhead transformer 22 . The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com