A prevention and control method of gas combustion caused by hard roof collapse in high gas stope

A technology with a hard roof and a collapsed roof, which is used in gas discharge, dust prevention, mining equipment, etc., can solve problems such as the lack of systematic consideration of safety accident prevention measures, achieve a simple and easy construction method, and reduce the probability of gas explosion. , the control effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

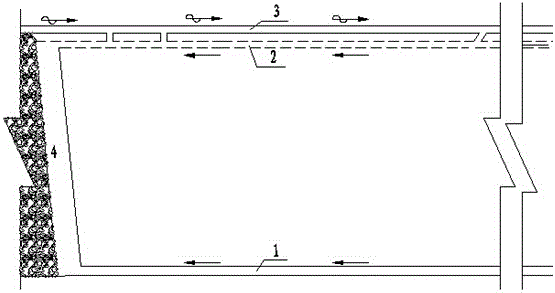

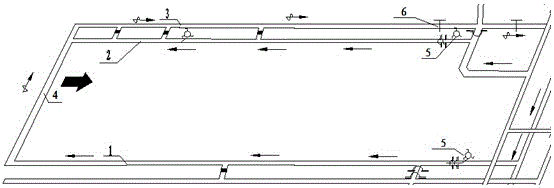

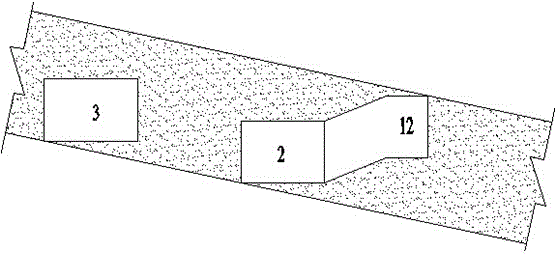

[0033] Such as Figure 1-8 As shown, the prevention and control method of the gas caused by the collapse of the hard roof in the high gas stope is realized through the following steps:

[0034] 1) Carry out advance pre-pumping of gas in this coal seam;

[0035] 2) Set up a Y-shaped combination ventilation lane on the upper part of the mining face to form a positive pressure parallel booster ventilation system on the mining face for ventilation;

[0036] 3) High-level drainage of gas in the upper area of the goaf;

[0037] 4) Pre-splitting blasting is carried out on the hard roof above the coal seam, high-pressure water injection is carried out on the pre-splitting deep holes after blasting, and high-pressure water is used to further crack the cracks generated by blasting. Generating heat to cool down.

[0038] As a preferred mode, the Y-shaped combined ventilation lane in the step 2) is composed of the lower air inlet lane 1, the upper air inlet lane 2 and the special ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com