Crawler-type automatic insecticide spraying machine

A sprayer, crawler-type technology, which is applied in the device, application, animal husbandry and other directions of catching or killing insects, to achieve the effect of large contact area, good effect and wide coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

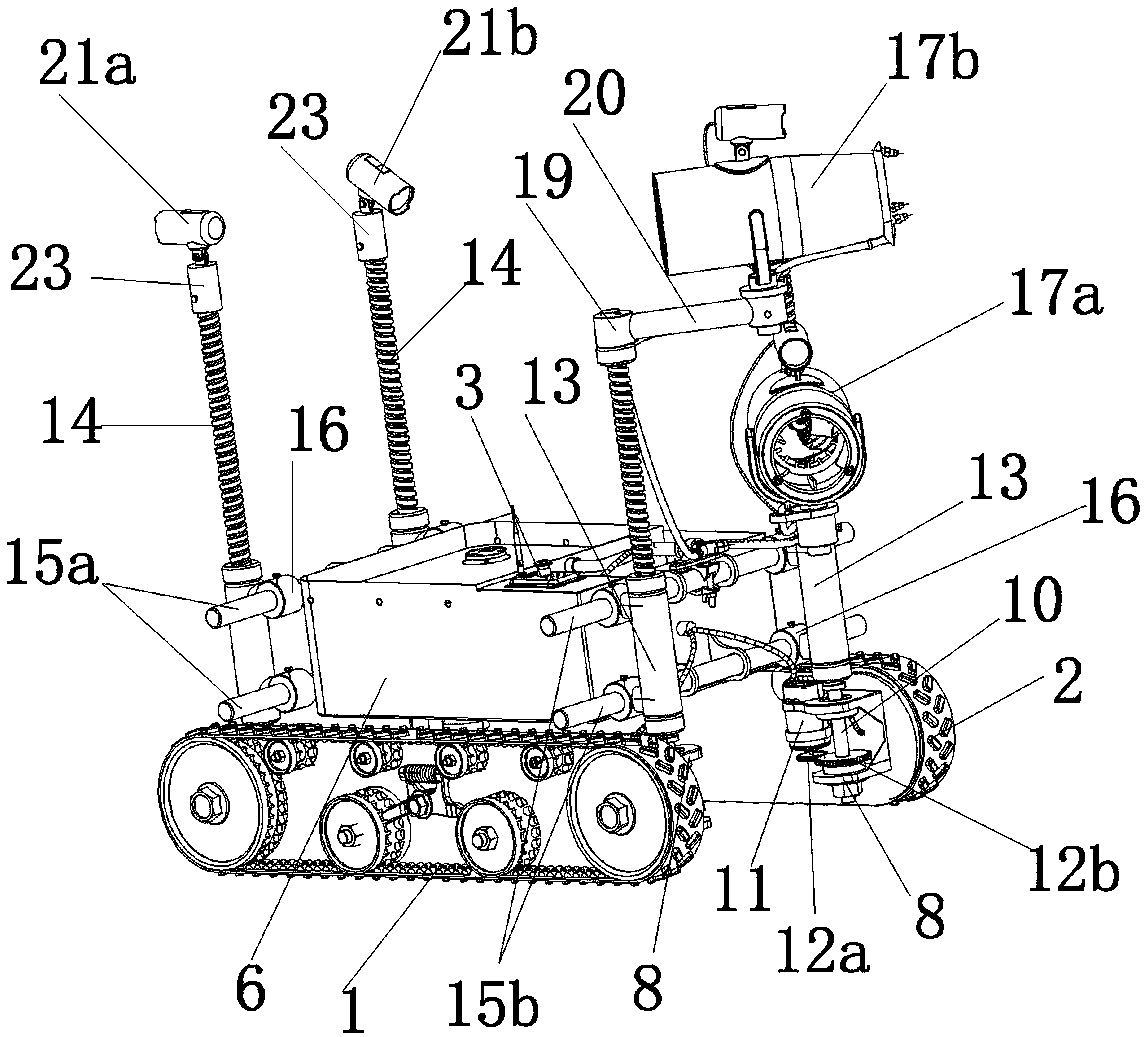

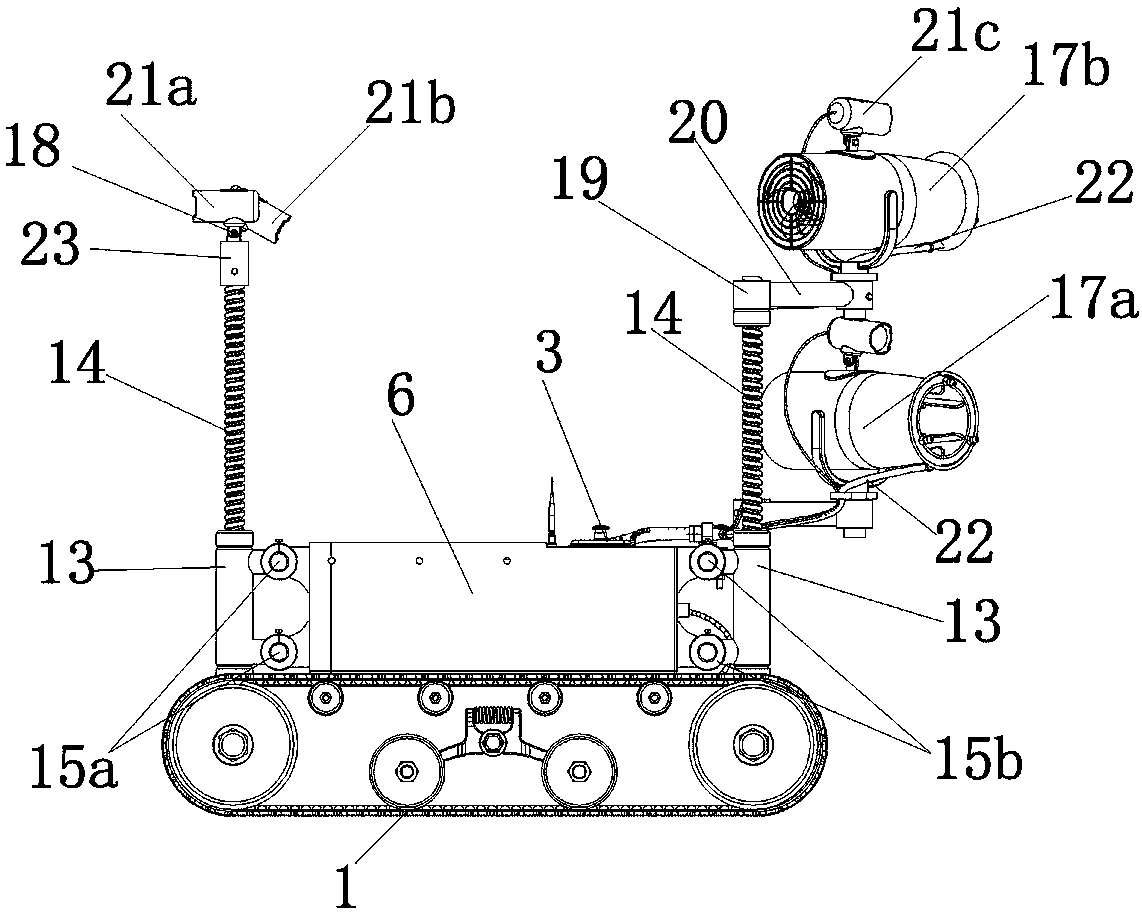

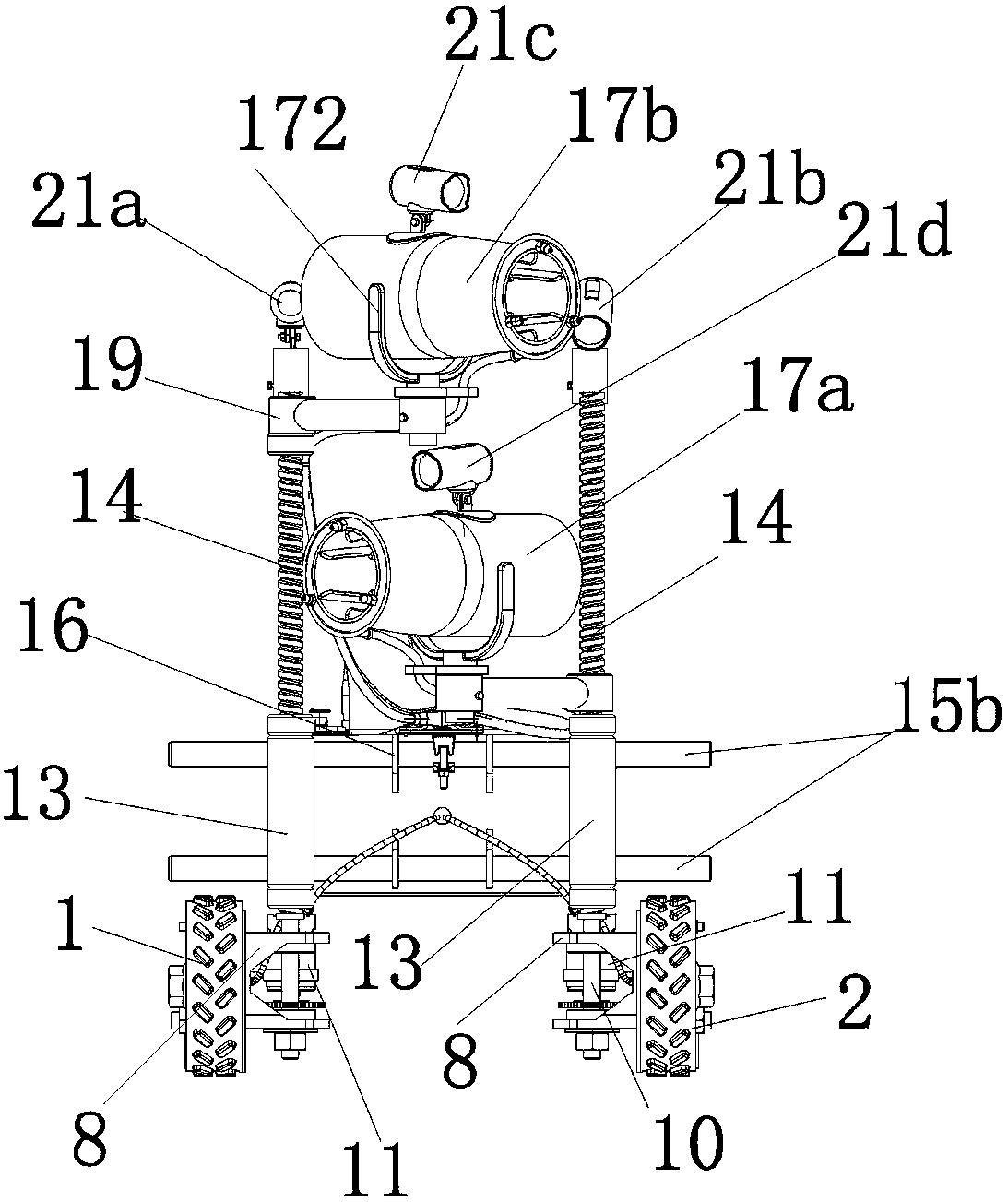

[0017] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] Depend on Figure 1-10 Provided, the present invention comprises the left walking crawler belt 1 and the right walking crawler belt 2 that are arranged in parallel and alternately, the inner sides of the front and rear ends of the left walking crawler belt 1 and the inner sides of the front and rear ends of the right walking crawler belt 2 are fixed with bearing housings 8, on the bearing housings 8 are The bearing is equipped with a vertical rotating shaft 10, and a motor 11 is fixed on one side of the bearing seat 8. A driving gear 12a is installed on the rotating shaft of the motor, and the driving gear 12a meshes with a driven gear 12b on the rotating shaft 10, forming The rotary drive structure of the rotary shaft, the upper end of the rotary shaft 10 is connected with a coaxially arranged screw 14, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com