A separated sieve of a flat round sieve for Oolong tea, the flat round sieve and a working method

A technology of flat and round sieve and oolong tea, which is applied in the direction of chemical instruments and methods, filtering, sorting, etc., can solve the problems of low production efficiency, low production efficiency, poor support effect, etc. Strong, structurally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the method of the present invention is described in further detail. It should be noted that the protection scope of the present invention shall include but not be limited to the technical content disclosed in this embodiment.

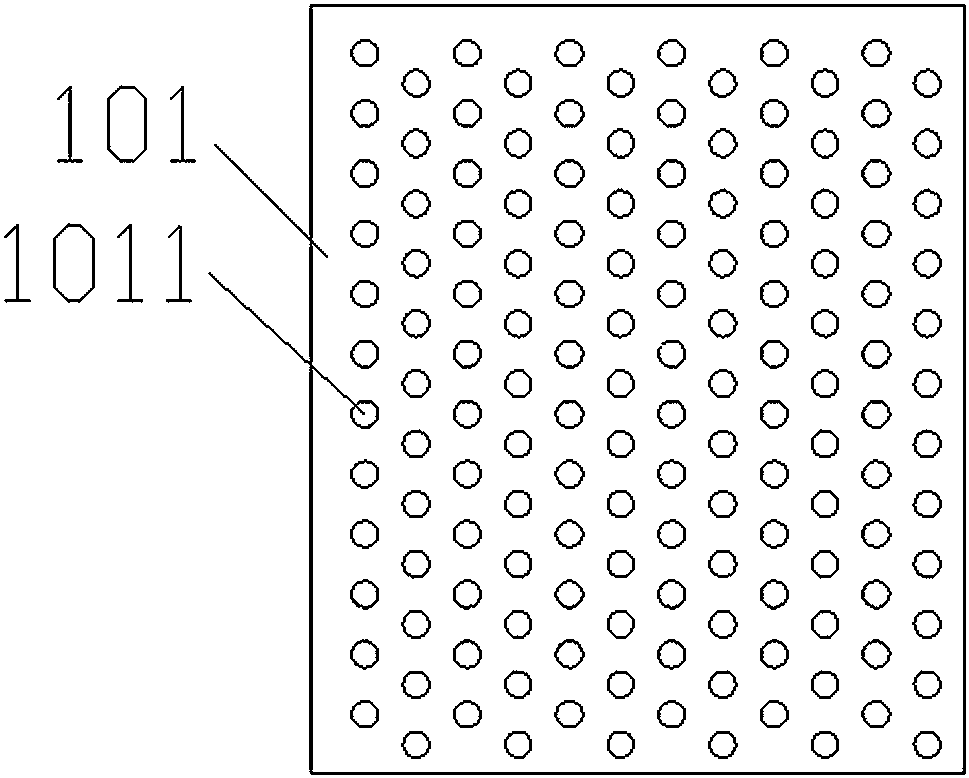

[0028] The flat round sieve for oolong tea of the present invention, the sieve is a sieve 101 made by punching out round holes 1011 on a stainless steel plate, the mesh number of the sieve is 1.5 mesh, and the center point of every three adjacent round holes The connecting lines form a triangle; the thickness of the stainless steel plate is 0.3-3 mm.

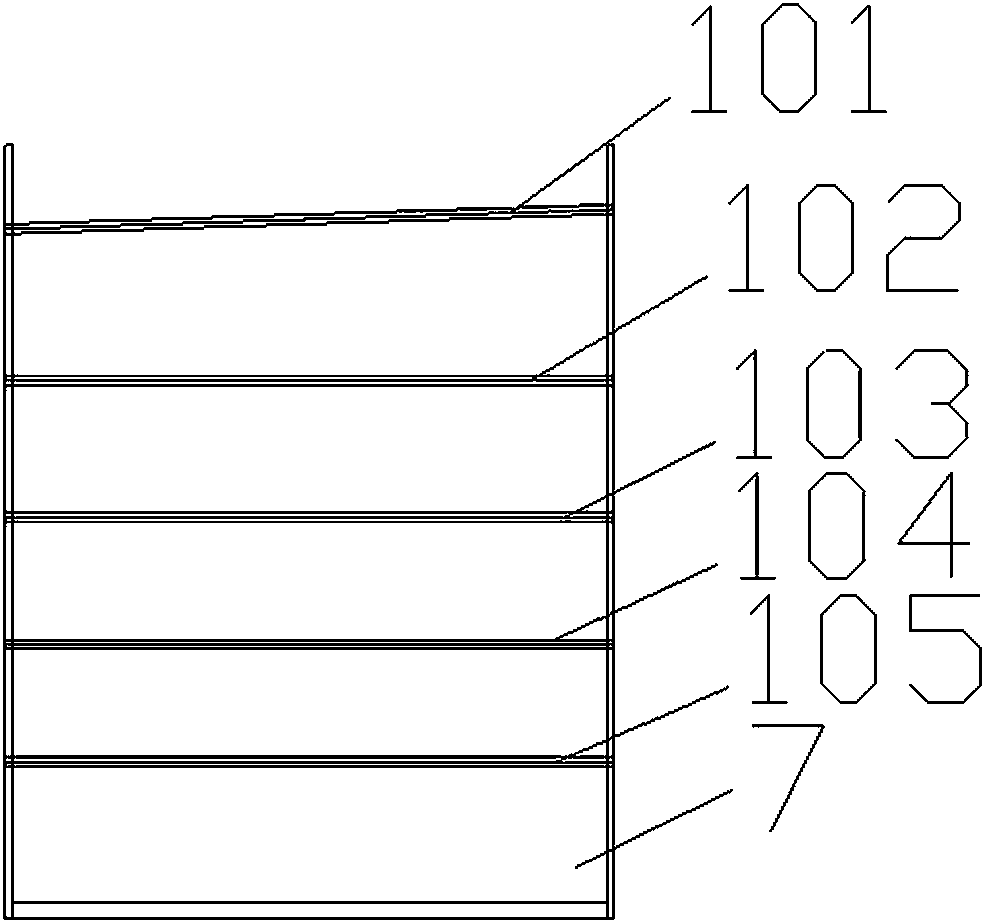

[0029] The oolong tea flat round sieve of the present invention comprises five layers of stacked and inclined screens, respectively the first layer of screen 101 is the sub-sieve, the second layer of screen 102, the third layer of screen 103, the fourth layer of screen 104 and The fifth layer of screen cloth 105 .

[0030] Further, the above-mentioned first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com