Granular partridge tea and preparation method thereof

A partridge tea and granular technology, which is applied in the field of granular partridge tea and its preparation, can solve the problems of too many crude fibers, unfavorable tea storage, brittleness and the like, and achieves strong aroma of Lingling, weakens natural coolness, and changes withering. effect of color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

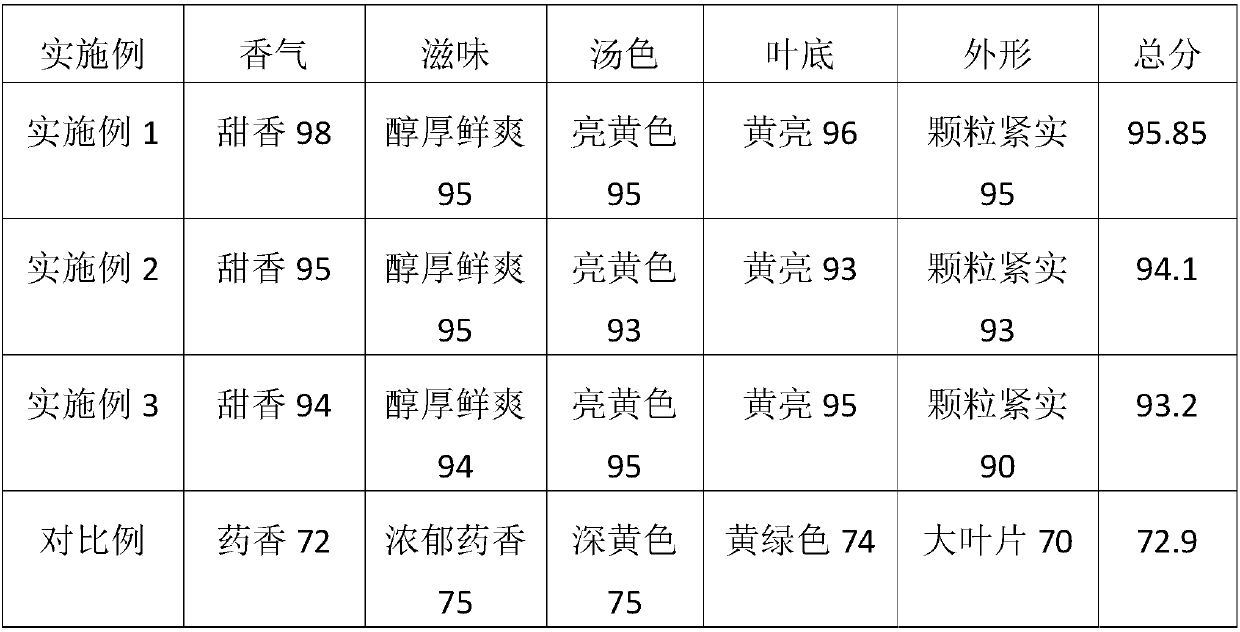

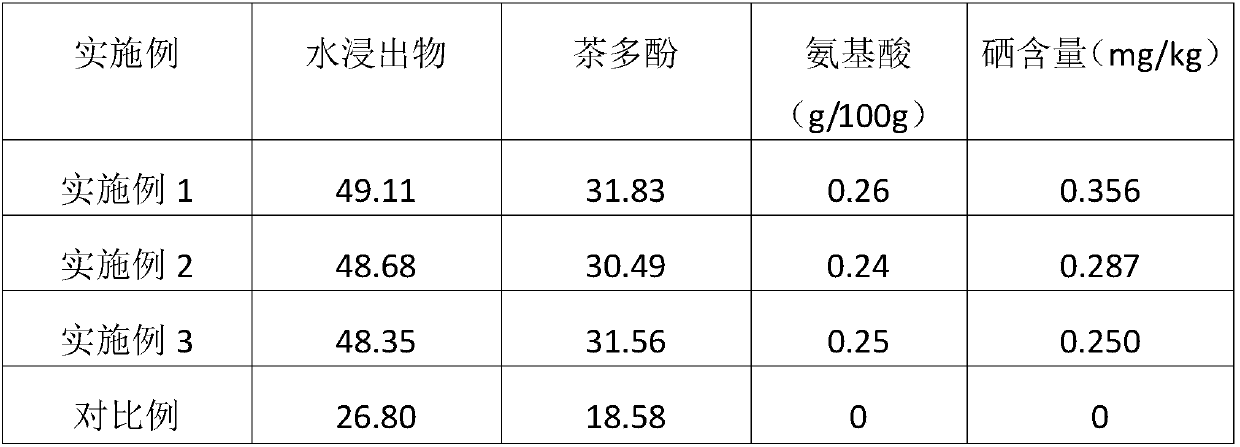

Examples

Embodiment 1

[0032] The present invention proposes a preparation method of granular partridge tea, comprising the following preparation steps:

[0033] S1. Use water vapor at 100° C. to spray for 1 minute to kill the greens. The water vapor used contains 0.2% edible salt by mass fraction.

[0034] S2. First, put the tea leaves softened by water vapor spray into the kneading machine, knead them gently and slowly into a ball; then put them into the extruder, extrude them in three directions, left and right Squeeze into granules.

[0035] S3. Before fermentation, spray the extract of Moringa oleifera leaf tea on the granulated partridge tea, then leave it to ferment for 2 hours at a fermentation temperature of 22-23°C. Present embodiment adopts temperature control machine to ferment naturally, although the progress is slow, it keeps the granular shape of partridge tea unchanged.

[0036] Moringa leaf tea extract is according to tea: water=1:2~4 volume ratio (preferably tea: water=1:3 volume...

Embodiment 2

[0042] The present invention proposes a preparation method of granular partridge tea, comprising the following preparation steps:

[0043] S1. Use water vapor at 90° C. for 0.5 minutes to spray and kill the greens. The water vapor used contains 0.1% edible salt by mass fraction.

[0044] S2. First, put the tea leaves softened by water vapor spray into the kneading machine, knead them gently and slowly into a ball; then put them into the extruder, extrude them in three directions, left and right Squeeze into granules.

[0045] S3. Before fermentation, spray the extract of Moringa oleifera leaf tea on the granulated partridge tea, and then leave it to ferment for 1.5 hours at a fermentation temperature of 22-23°C. Present embodiment adopts temperature control machine to ferment naturally, although the progress is slow, it keeps the granular shape of partridge tea unchanged.

[0046] The extract of Moringa leaf tea is made according to the volume ratio of tea: water = 1:3, and ...

Embodiment 3

[0052] The present invention proposes a preparation method of granular partridge tea, comprising the following preparation steps:

[0053] S1, adopt 85 DEG C water vapor, 2 minutes spray and finish, and the used water vapor contains the edible salt that mass fraction is 0.3%.

[0054] S2. First, put the tea leaves softened by water vapor spray into the kneading machine, knead them gently and slowly into a ball; then put them into the extruder, extrude them in three directions, left and right Squeeze into granules.

[0055] S3. Before fermentation, spray the extract of Moringa oleifera leaf tea on the granulated partridge tea, and then leave it to ferment for 1 hour at a fermentation temperature of 22-23°C. Present embodiment adopts temperature control machine to ferment naturally, although the progress is slow, it keeps the granular shape of partridge tea unchanged.

[0056] The extract of Moringa leaf tea is made according to the volume ratio of tea: water = 1:3, and is boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com