Preparation method of 2,2,3,3,3-pentafluoropropanol

A technology of pentafluoropropanol and pentafluoropropane, which is applied in the field of preparation of 2,2,3,3,3-pentafluoropropanol, can solve the problems of expensive reagents, many synthesis steps, complicated operation, etc., and achieve the synthesis Fewer steps, high activity, simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The batch liquid phase fluorination reaction was carried out in a stirred 300mL stainless steel autoclave. Put 1g of Pt-Fe into the reactor in sequence 3 o 4 / C catalyst (wherein the mass percent composition of Pt is 1, and the mass percent composition of Fe is 0.5%), 100g isopropanol, 5g potassium persulfate, 80g 1,1,1,2,2-pentafluoropropane, Raise the temperature to 80°C, cool down after 2 hours of reaction, and analyze the organic phase by gas chromatography, the results show that the conversion rate of 1,1,1,2,2-pentafluoropropane is 85.3%, 2,2,3,3,3-pentafluoropropane Alcohol selectivity was 78.1%.

Embodiment 2~4

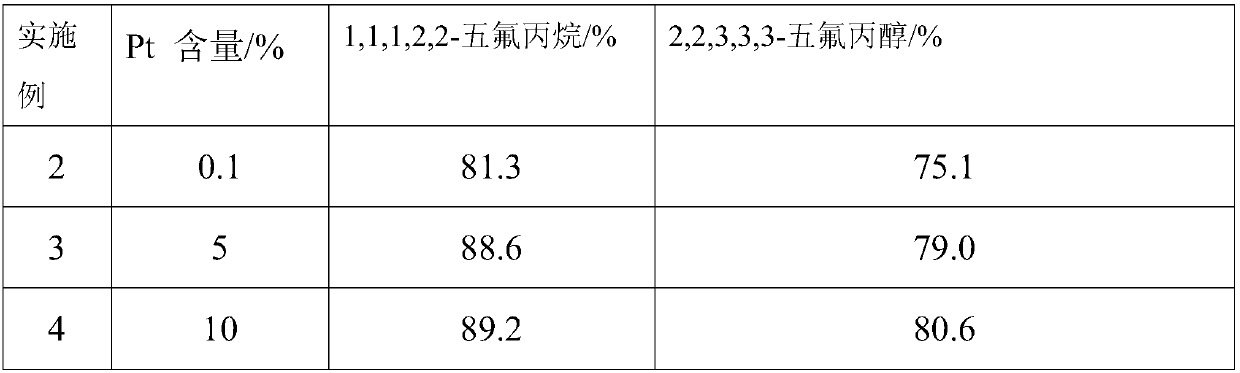

[0018] Examples 2-4 The method for preparing 2,2,3,3,3-pentafluoropropanol is the same as that of Example 1, the difference is that the mass percentage of Pt is changed, and the reaction results are shown in Table 1.

[0019] Table 1

[0020]

Embodiment 5~7

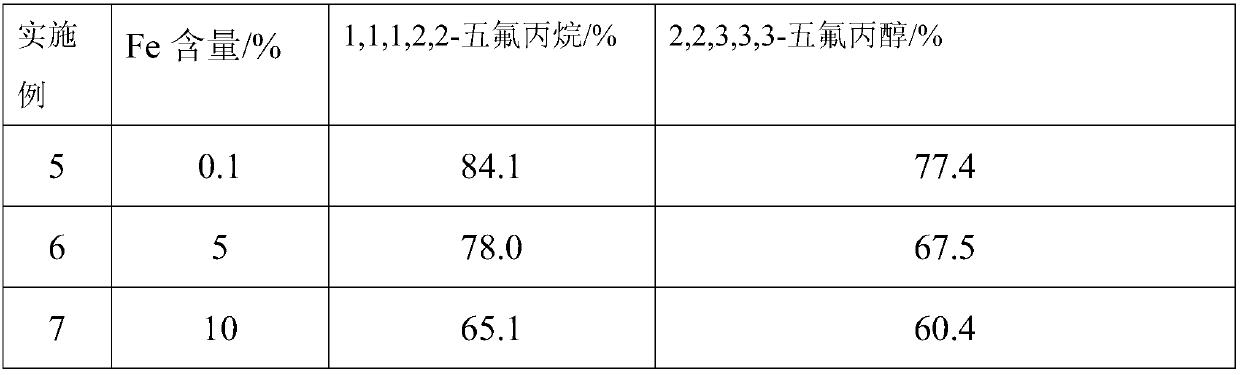

[0022] The method for preparing 2,2,3,3,3-pentafluoropropanol in Examples 5-7 is the same as that in Example 1, except that the mass percentage of Fe is changed. The reaction results are shown in Table 2.

[0023] Table 2

[0024]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com