High-deformation-resistant asphalt pavement structure

An asphalt pavement, anti-deformation technology, applied to roads, roads, on-site cohesive pavements, etc., can solve problems such as low asphalt grade, lateral shearing of wrapping, rutting deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

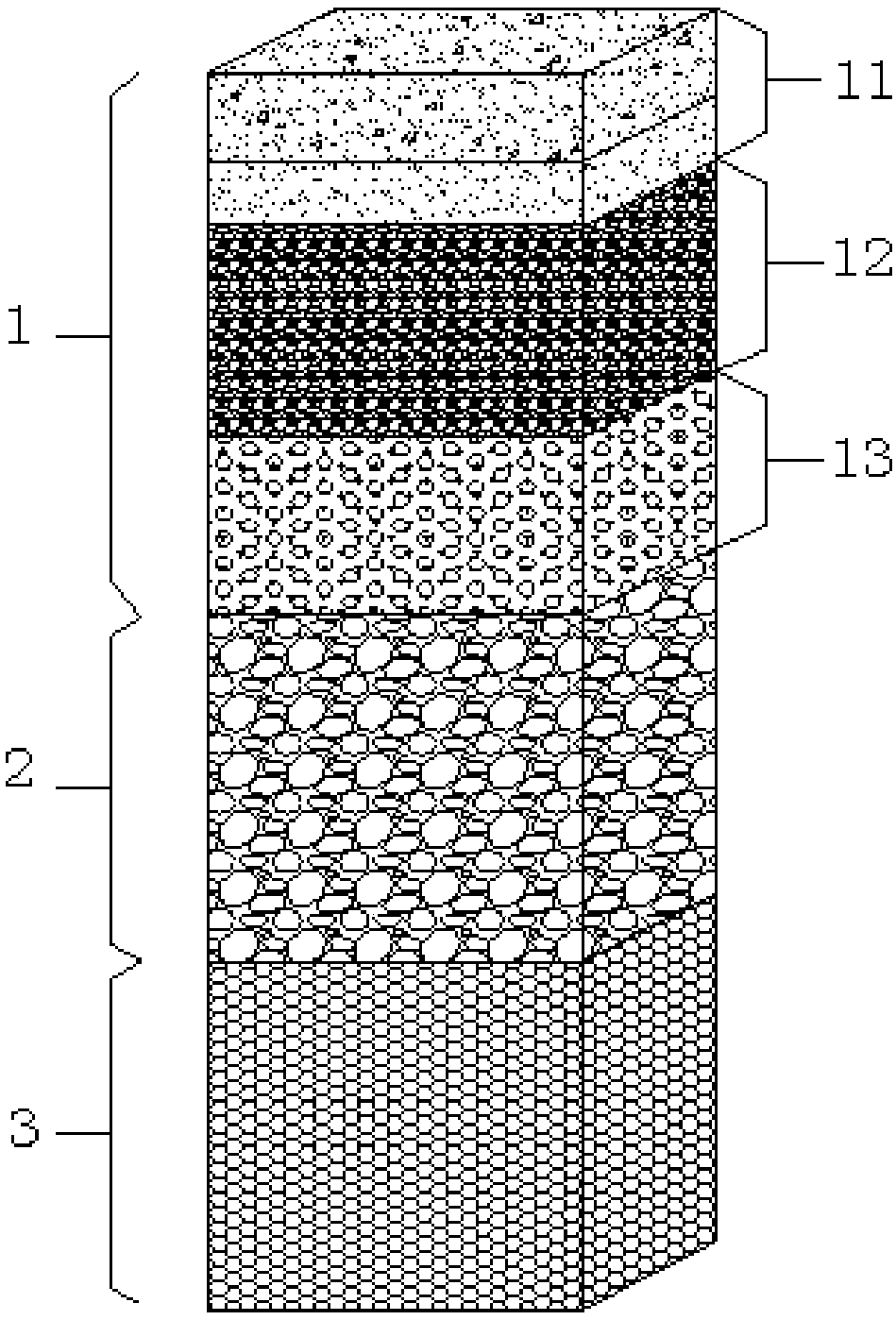

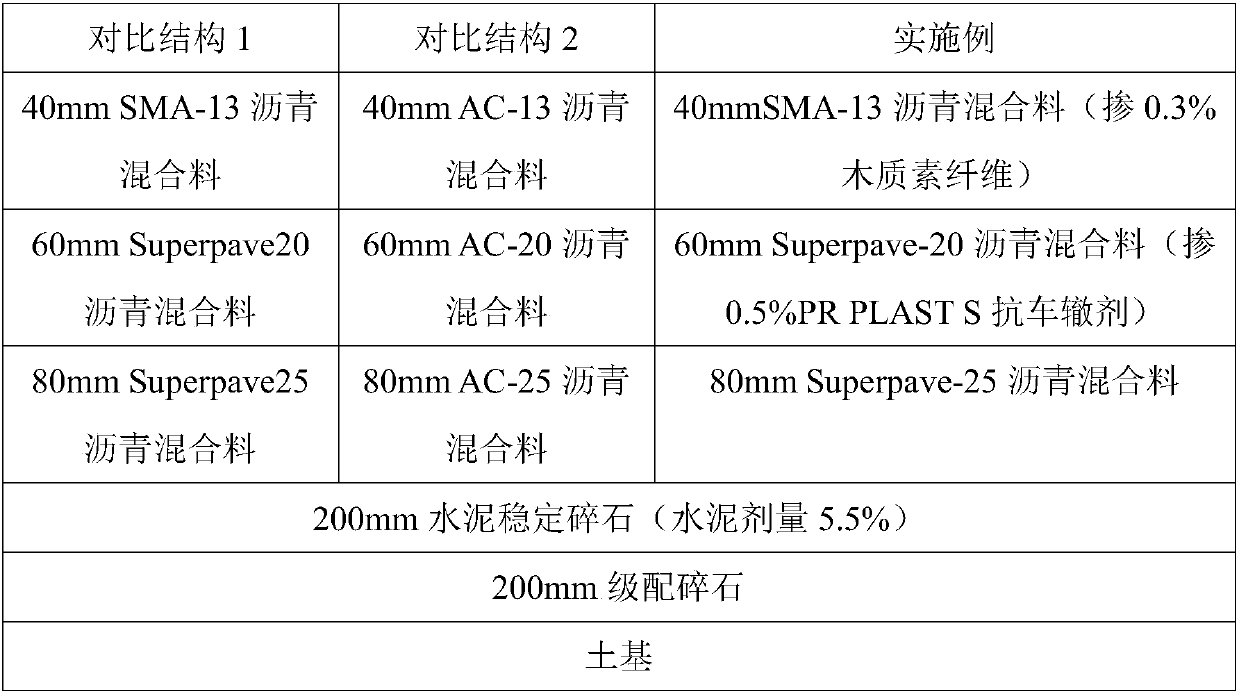

[0034] Such as figure 1 A high-deformation-resistant asphalt pavement structure is shown. The pavement structure includes a high-deformation-resistant asphalt pavement, a deformation-resistant semi-rigid base and a subbase in sequence from top to bottom; wherein, the asphalt pavement includes a surface wear layer, and the middle The surface layer and the lower layer; the semi-rigid base layer is anti-deformation cement stabilized crushed stone; the sub-base layer is graded crushed stone.

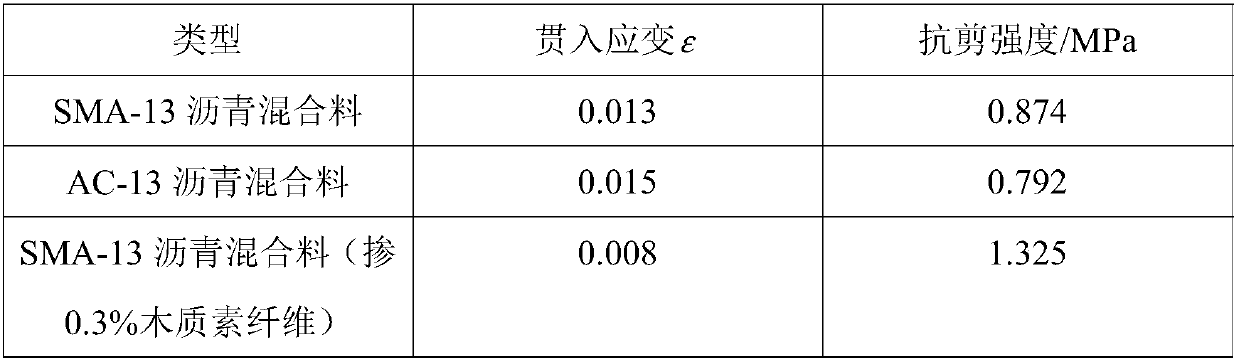

[0035] Among them, the surface wear layer is made of SMA-13 graded asphalt mixture with a thickness of 35-50 mm, and the material mass ratio is: SBS modified asphalt: first mineral material: lignin fiber = 6.0-6.2:100:0.3-0.4, The nominal maximum particle size is 13.2mm.

[0036] Among them, the middle surface layer adopts Superpave-20 graded asphalt mixture, the thickness is 50-70mm, and the material mass ratio is: SBS modified asphalt: the second mineral material: PR PLAST S anti-ruttin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com