Efficient condenser with fixed-type flow-around torsion belts

A fixed, condenser technology, which is applied in steam/steam condensers, heat exchanger shells, lighting and heating equipment, etc. It can solve the problems of aggravated fouling on the inner wall of the pipeline, increased equipment costs, and affects the popularization and application of condensers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

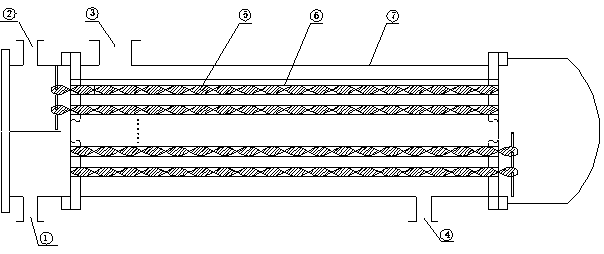

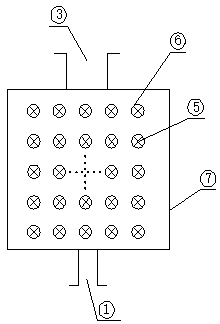

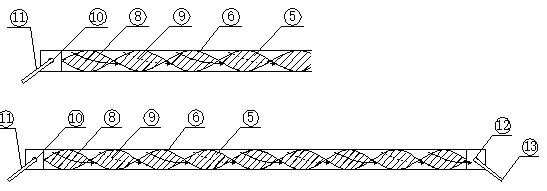

[0012] Such as figure 1 As shown in the figure, the fixed flow-around twisted belt high-efficiency condenser, the exhaust steam of the steam turbine enters the condenser through the inlet (3) and goes to the shell side, and the circulating cooling water flows into the condenser tube (6) through the inlet (1) and goes through the tube side, fixed The twisted belts (5) are inserted into the condensation pipe (6), and each fixed twisted belt (5) is arranged through the fixing holes (10) and (12) through the fixing rods (11) and or (13). Single-ended or double-ended. When the cooling water flows through the tube side of the condensing tube at a certain speed, the fixed winding twist belt makes the circulating cooling water in the condensing tube rotate and flow forward. During operation, the circulating cooling water in the condensing tube is divided into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com