Structure for matching side plate with water chamber of heat radiator

A matching structure and radiator technology, applied in heat exchanger shells, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of increased manufacturing costs, complex structural design, complex production process, etc., to reduce manufacturing costs , Reasonable structural design and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

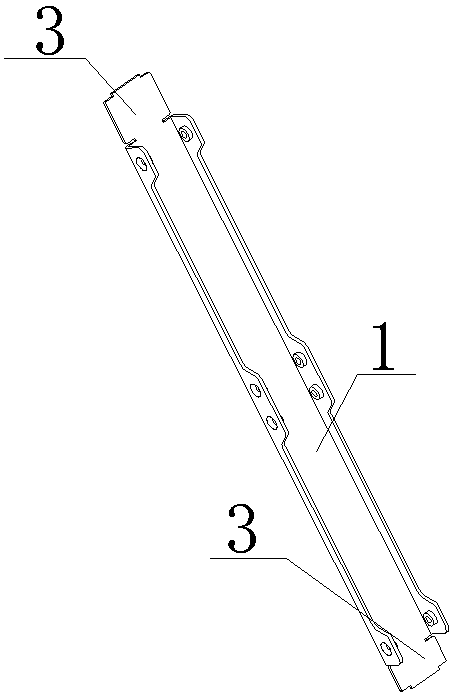

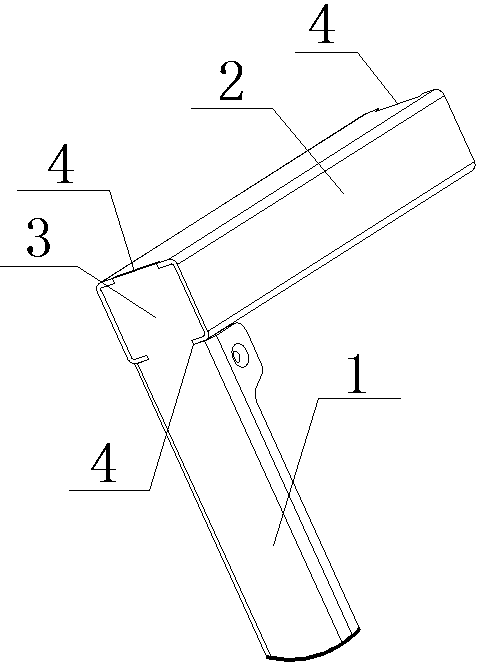

[0021] A radiator side plate and water chamber matching structure of the present invention, the two ends of the side plate 1 are respectively provided with limit baffles 3, the two ends of the water chamber 2 are opening structures, and the outer edge of the opening is provided with a limit stop The notch groove 4 matched with the plate 3, the limit baffle 3 is clamped in the notch groove 4, and the limit baffle 3 and the notch groove 4 are fixedly connected by brazing; the cross-sectional shape of the side plate 1 It is a U-shaped structure, and the limit baffle 3 is arranged parallel to the outer wall of the side plate 1 and located on the same plane.

Embodiment 2

[0023] A radiator side plate and water chamber matching structure of the present invention, the two ends of the side plate 1 are respectively provided with a convex-shaped limit baffle 3, the two ends of the water chamber 2 of the rectangular square tube structure are opening structures, the opening There is a notch groove 4 matched with the limit baffle 3 on the outer edge, the limit baffle 3 is clamped in the notch groove 4, and the limit baffle 3 and the notch groove 4 are brazed Fixed and connected; the cross-sectional shape of the side plate 1 is a U-shaped structure, and the limit baffle 3 is arranged parallel to the outer wall of the side plate 1 and located on the same plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com