A Dense Concentrating Photovoltaic Cell Array with Reduced Mismatch Loss

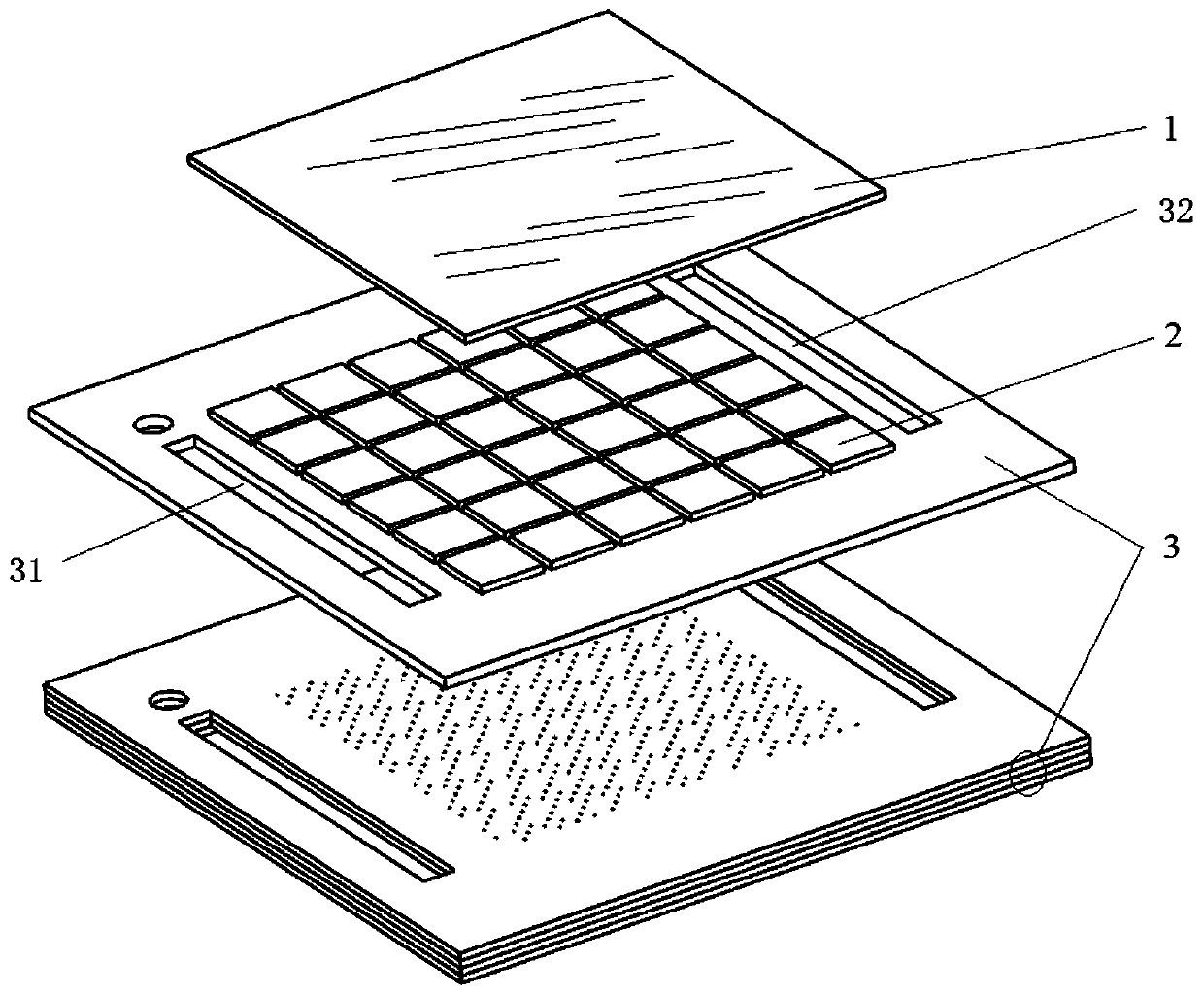

A battery array and concentrating photovoltaic technology, applied in the field of solar energy utilization, can solve the problems of DA-CPV system cost increase, large optical loss, etc., and achieve the effect of improving output characteristic curve, increasing power output, and optimizing heat transfer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

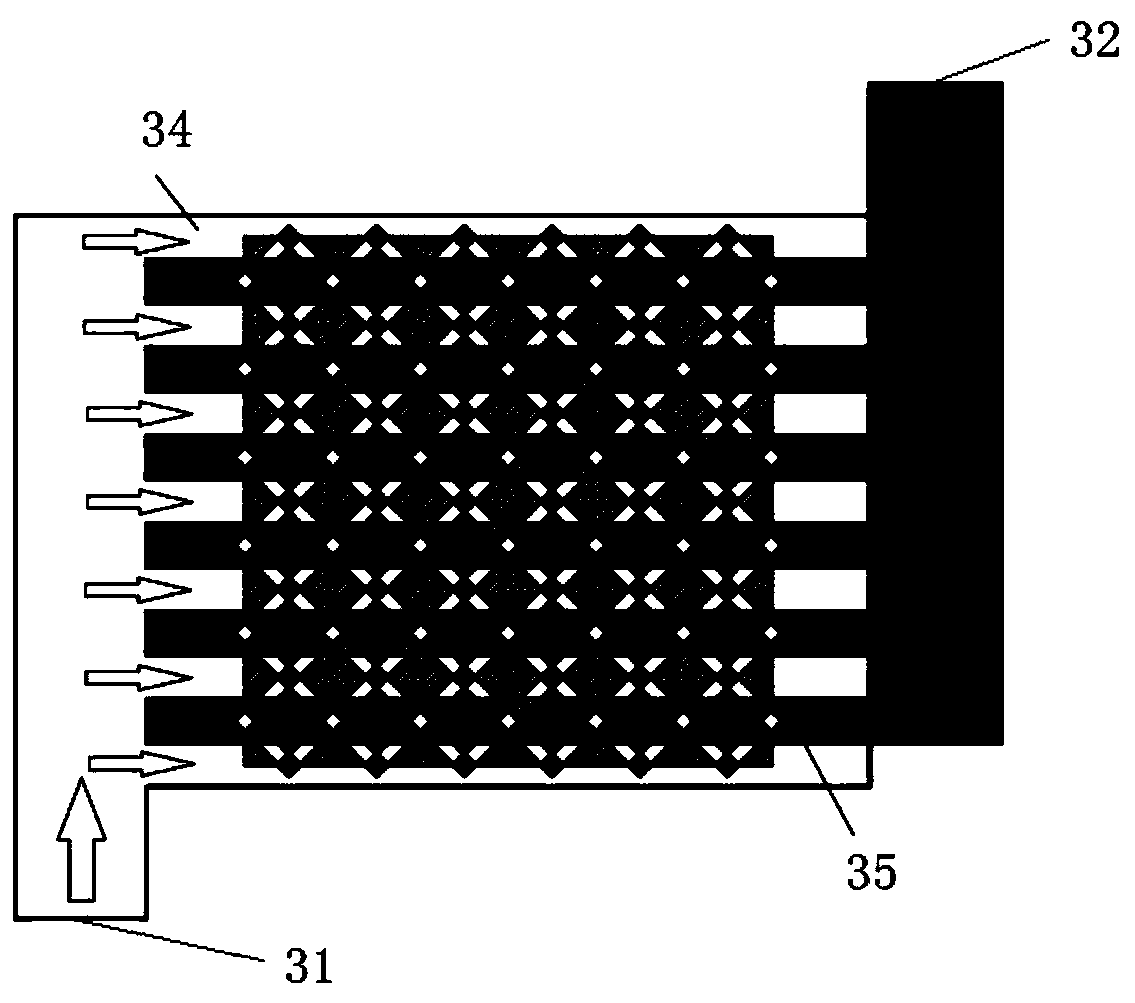

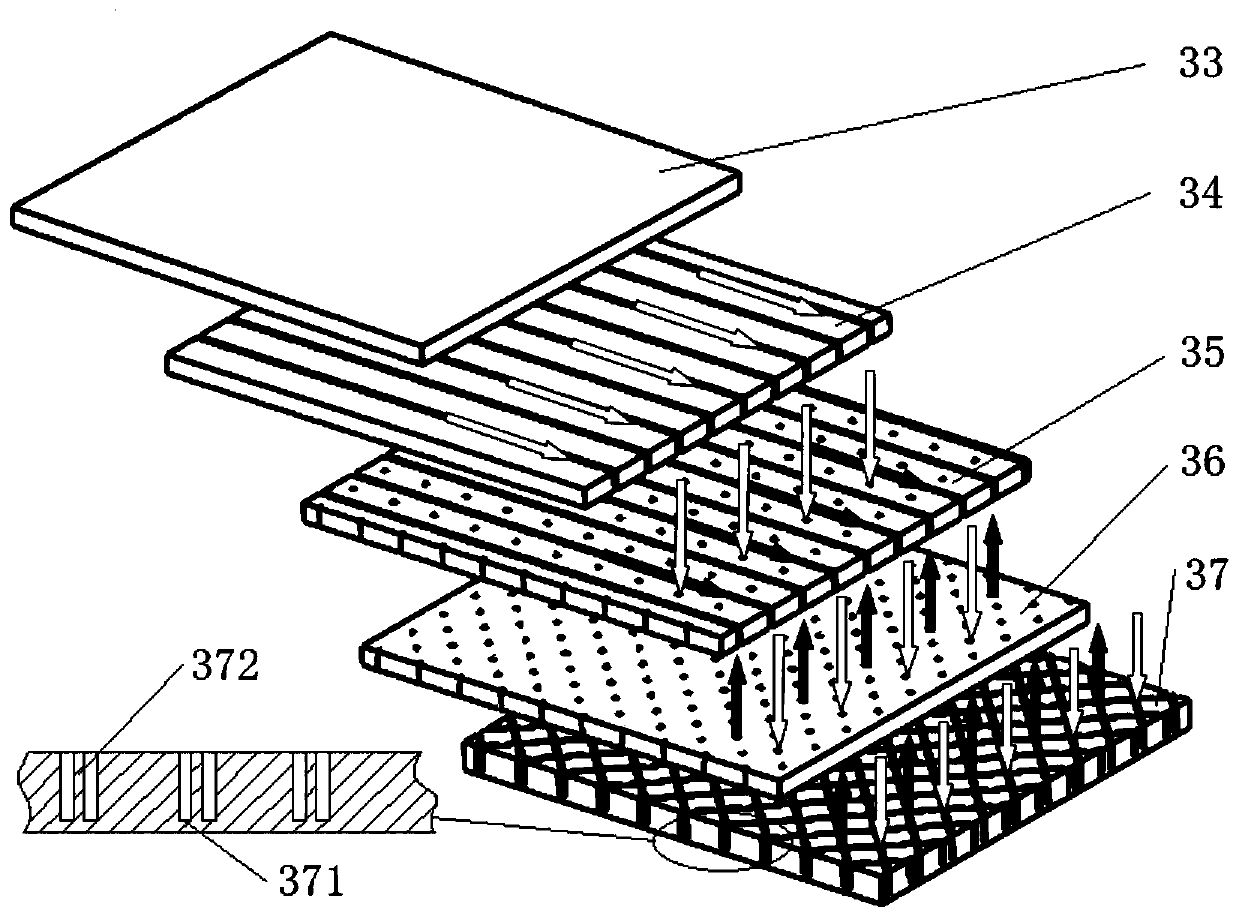

Embodiment 1

[0043] Preferably, the connection is performed in a square-arranged dense array with four corners rotationally symmetrically connected. This embodiment adopts Figure 5 Gaussian distribution lighting conditions shown, select Image 6 The 6×6 square concentrating photovoltaic dense battery array shown, a total of 36 square concentrating photovoltaic cells, each battery is 10mm×10mm, arranged into a 6×6 battery array, and each battery is from 1 -36 for numbering. The connection method is like Figure 7 As shown, the battery array is divided into 4 sub-modules with the coordinate axis origin as the center and the coordinate axis as the boundary line, and each sub-module includes 9 concentrating cells symmetrical about the origin. Connect the batteries numbered 1, 2, 3, 7, 8, 9, 13, 14, 15 in parallel, named as a square array with four corners rotationally symmetrically connected to the fourth submodule 234, and numbered 4, 5, 6, 10, The batteries of 11, 12, 16, 17, and 18 are con...

Embodiment 2

[0045] Preferably, the connection is made in a square-arranged dense array diagonally rotationally symmetrical connection mode, this embodiment adopts Figure 5 Gaussian distribution lighting conditions shown, select Image 6 The 6×6 square concentrating photovoltaic dense battery array shown, a total of 36 square concentrating photovoltaic cells, each battery is 10mm×10mm, arranged into a 6×6 battery array, and each battery is from 1 -36 for numbering. The difference from the first embodiment is that the connection method of the dense concentrating photovoltaic cell array is as follows: Picture 9 As shown, in order to adapt to different voltage and current requirements, this embodiment adopts a diagonal rotation symmetrical connection mode to achieve effective complementarity with the first embodiment. Parallel the batteries numbered 1, 7, 13, 19, 25, 31 on both sides of the battery array, and name the square array diagonally and rotationally symmetrically connected to the fir...

Embodiment 3

[0047] Preferably, the connection is performed in a circular arrangement of a dense array containing special-shaped cells in a rotationally symmetrical connection at four corners. The difference from the first and second embodiments is that the array shape is circular and consists of 52 photovoltaic cells. Including square concentrating cells and special-shaped cells. Each cell is connected to form an array and then used in the concentrated photovoltaic power generation system. Its connection method is like Picture 11 As shown, with the origin of the coordinate axis as the center and the coordinate axis as the boundary, the battery array is divided into four sub-parts, which will be numbered 1, 2, 5, 6, 7, 11, 12, 13, 14, 19, 20 , 21, 22 batteries are connected in parallel, named as a circular arrangement. The four corners of the shaped battery array are rotationally symmetrically connected to the fourth sub-module 254, which will be numbered 3, 4, 8, 9, 10, 15, 16, 17, 18, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com