Electric motor and manufacturing method thereof

A motor and housing technology, applied in the field of motor and its manufacturing, can solve the problems of output (poor power density, excessive temperature rise, increase in manufacturing cost, etc.), reduce dynamic power, reduce flow resistance, oil circulation, etc. Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] Now, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings. As much as possible, the same reference numerals will be used to designate the same or like parts throughout the drawings, and descriptions thereof will be replaced with the first description. Expressions in the singular include plural concepts unless the context clearly differs. Also, in the disclosed embodiments of the present invention, detailed descriptions of known elements or functions are omitted if they are considered to unnecessarily obscure the subject matter of the present invention. In addition, it should be understood that the drawings are only for easy understanding of the embodiments of the present invention, and thus the embodiments are not limited by any details of the drawings.

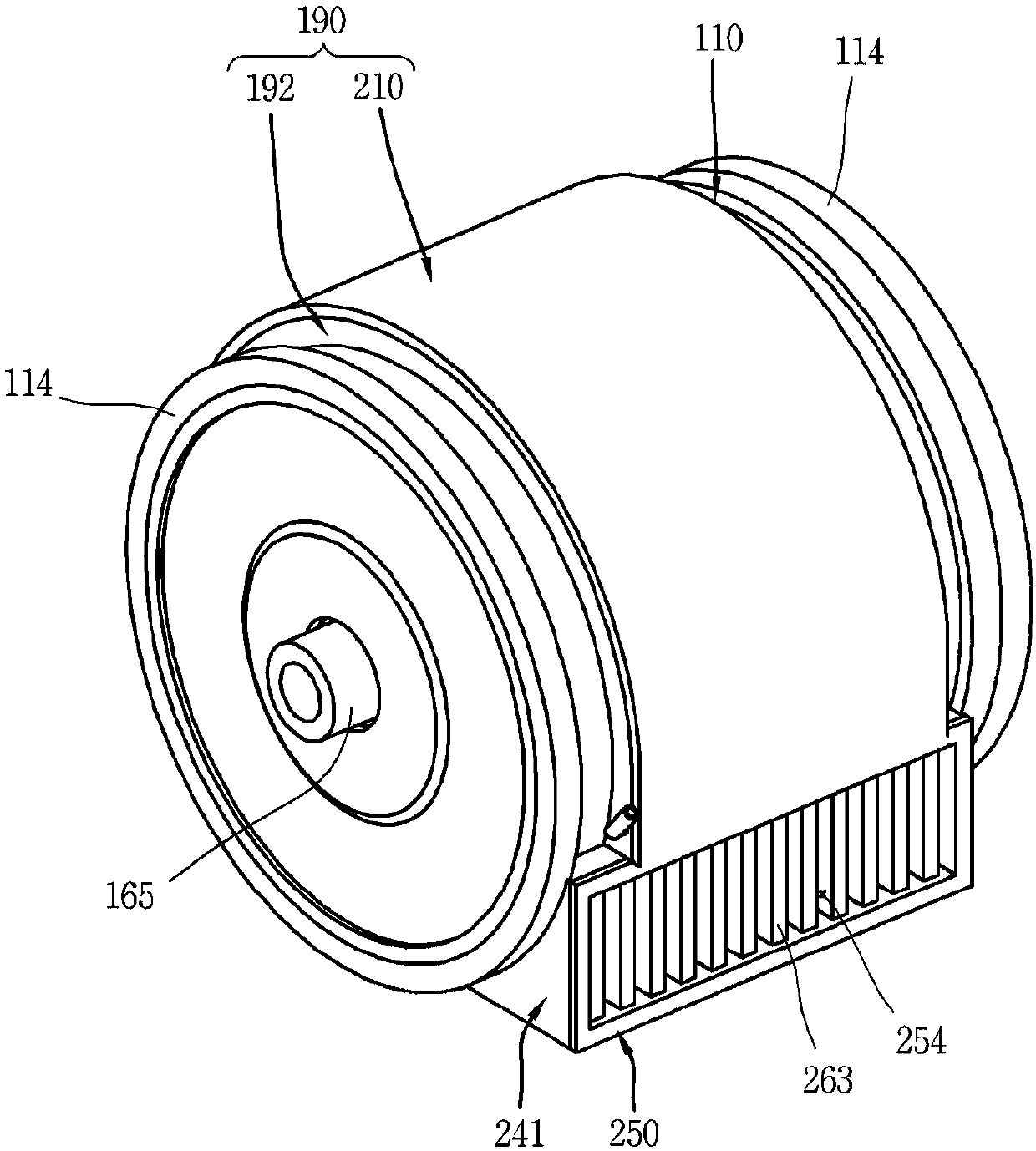

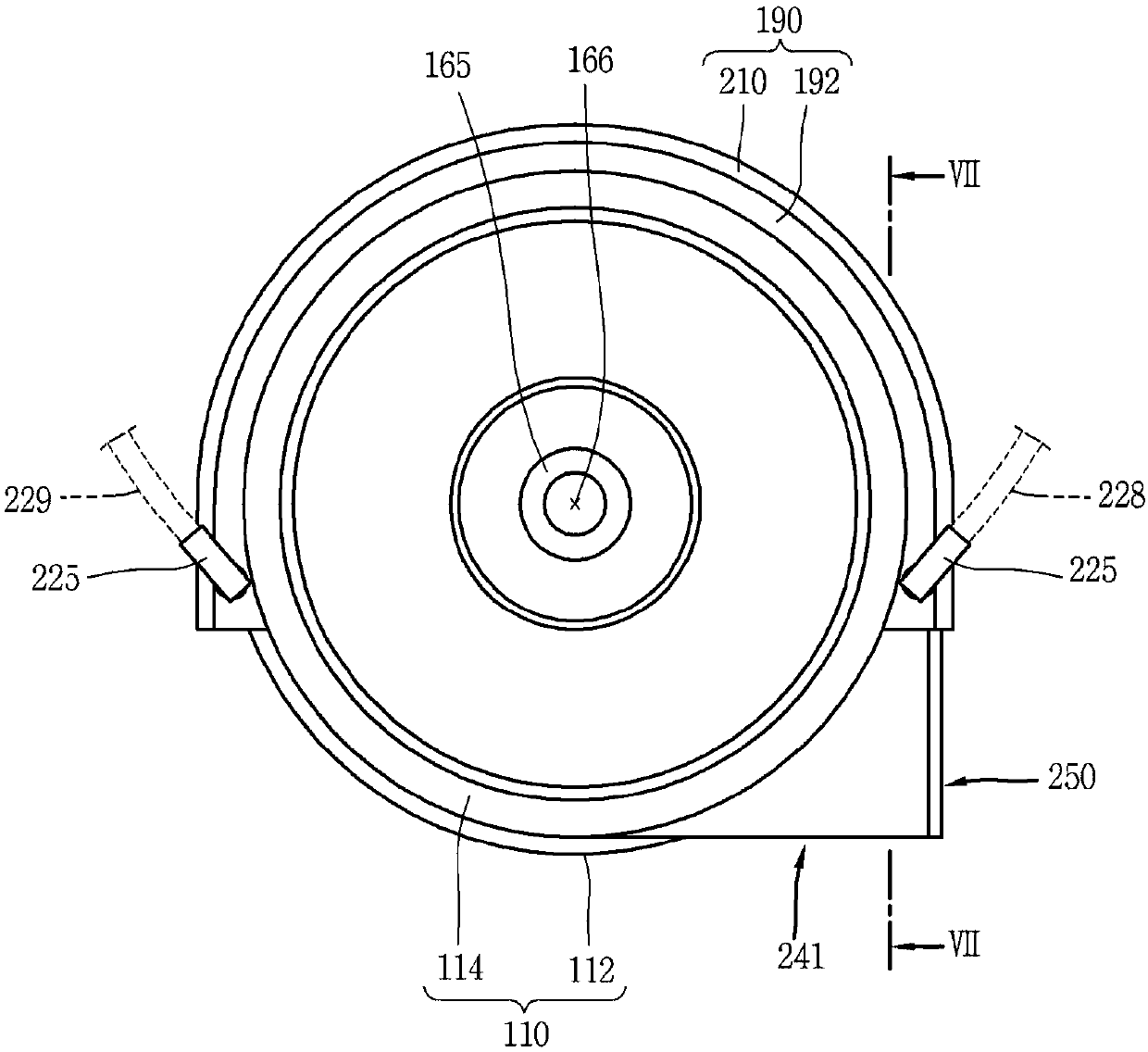

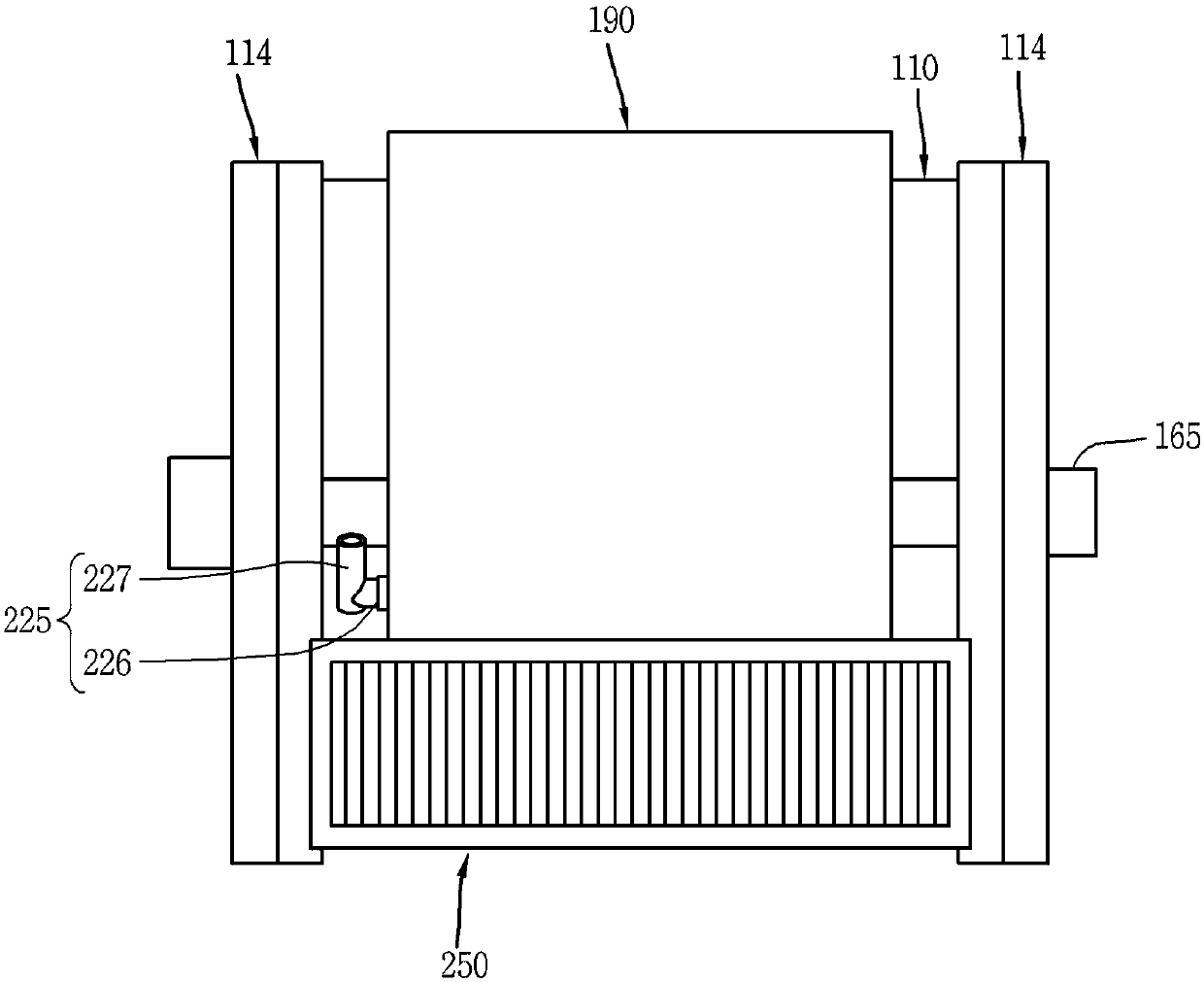

[0093] Such as Figure 1 to Figure 5 As shown, a motor according to an embodiment of the present invention includes: a housing 110 in which an accommod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com