Automatic shelling device and method for bamboo shoots

An automatic technology for bamboo shoots, which is applied in the field of deep processing of bamboo shoots, can solve the problems of large differences in characteristics of bamboo shoots, discounted peeling speed, and large labor demand, so as to ensure continuous and stable operation, ensure product quality, and improve processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

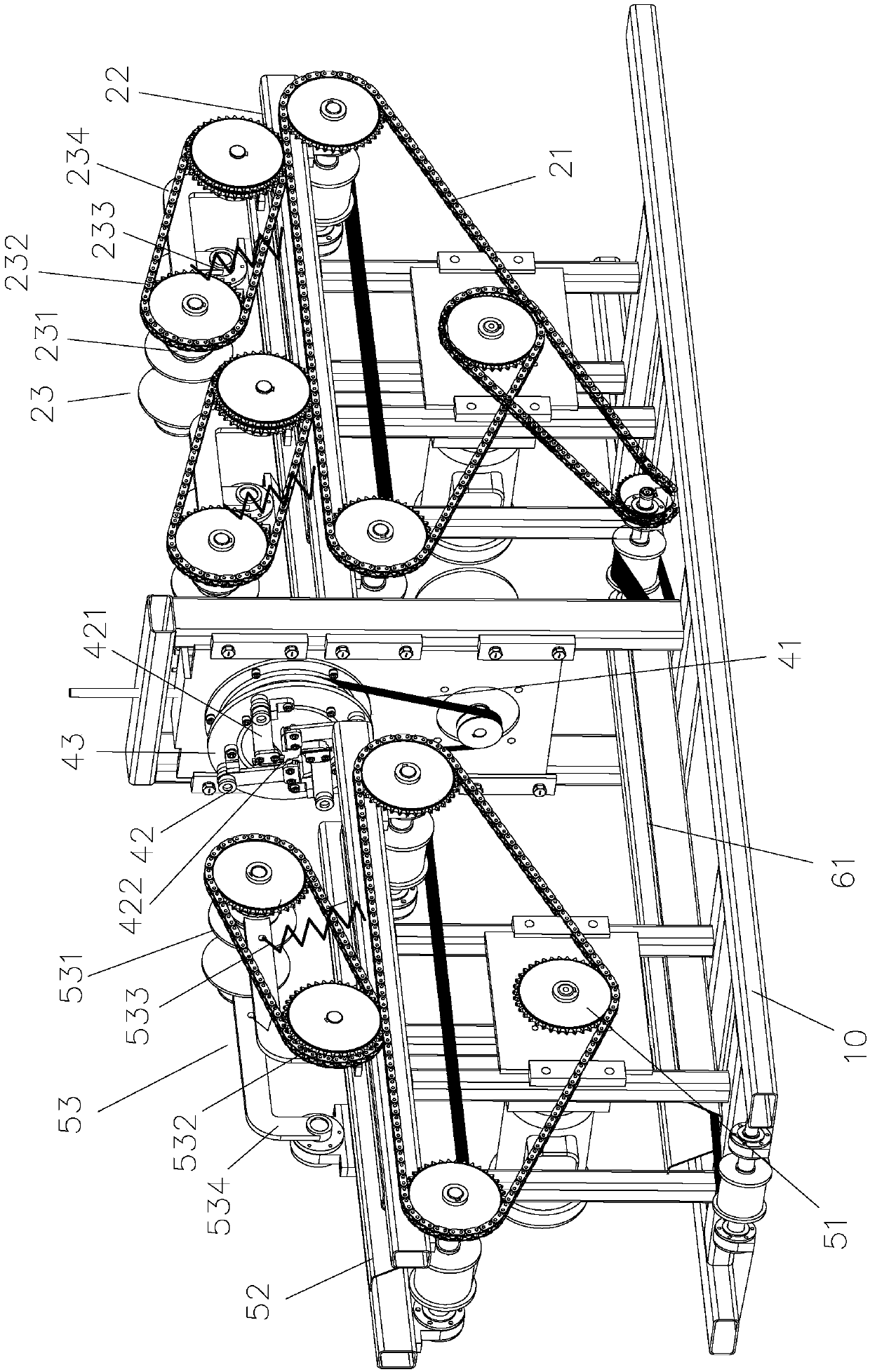

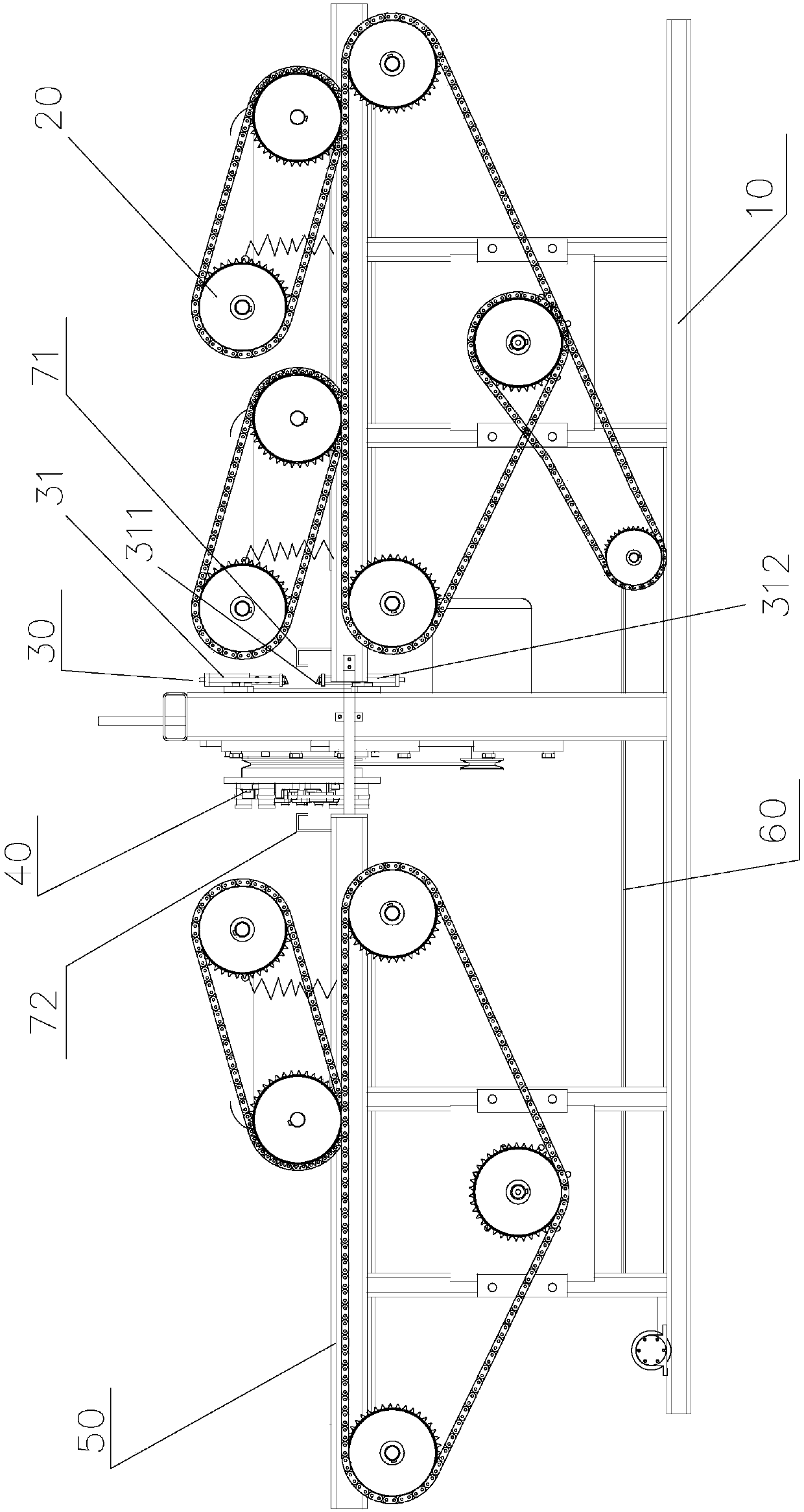

[0022] Such as figure 1 and figure 2 As shown, the bamboo shoots automatic shelling equipment of the present invention comprises a feeding mechanism 20, a shelling device 30, a shelling device 40, and a discharging mechanism 50 arranged on the same straight line, wherein:

[0023] The feeding mechanism 20 includes a feeding conveyor belt 22 forming a V-shaped groove. The feeding conveyor belt 22 runs under the drive of the feeding chain transmission member 21. The top of the feeding conveyor belt 22 is provided with a downward elastic compression V-shaped groove. Some feeding pressing wheel elastic members 23 of bamboo shoots, the design of a plurality of feeding pressing wheel elastic members 23 is conducive to compressing various parts of different diameters on the bamboo shoots, so that the bamboo shoots are conveyed firmly in a moderately compacted state .

[0024] The cutting shell device 30 comprises a number of cutting cutters 31 that are uniformly distributed along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com