Grinding device used for solid waste recovery

A technology of solid waste and pressing rollers, which is applied in the direction of grain processing, etc., can solve the problems that affect the efficiency of equipment rolling, waste extrusion splashing, scattering, etc., and achieve the effect of safety and stability of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

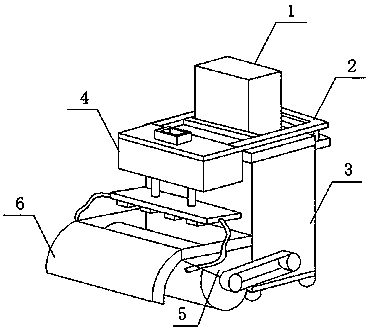

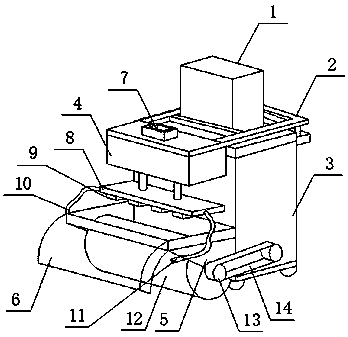

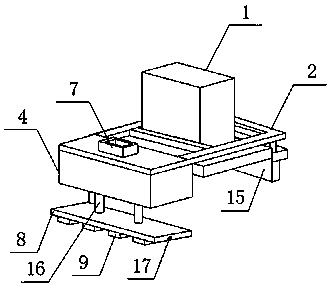

[0020] see Figure 1-3 As shown, a crushing device for solid waste recovery includes a chassis 3 and an underframe 5, a fixed frame 2 is installed on the top of the cabinet 3, a power supply box 1 is installed on the fixed frame 2, and a clamping plate 15 is arranged at one end of the fixed frame 2, The other end of the fixed frame 2 is installed with a water tank 4, the top of the water tank 4 is provided with a water inlet 7, and the bottom of the water tank 4 is connected to two connecting pipes 16, the connecting pipes 16 are connected to the spray frame 8, and several nozzles 9 are arranged at the bottom of the spray frame 8, and the two ends of the spray frame 8 Connecting holes 17 are all arranged, and the water pipes 10 are connected on the connecting holes 17, and the bottom frame 5 is arranged on the side wall of the bottom of the cabinet 3; The waste material splashed during rolling is blocked to effectively prevent the material from splashing during rolling, and a ...

Embodiment 2

[0022] Please continue to refer to Figure 1-3 The difference between it and the above-mentioned embodiment is that the clamping plate 15 at one end of the fixed frame 2 is attached to the outer wall on one side of the top of the cabinet 3, and the water tank 4 at the other end of the fixed frame 2 is attached to the outer wall on the other side of the top of the cabinet 3. The water tank 4 is fixedly connected with the chassis 3 by using the fixing frame 2, so that the overall structure of the device is safer and more stable. The water tank 4 is connected with the water pump inside the cabinet 3 through pipelines, and the water tank 4 is connected with the spray rack 8 and the spray pipe 11 by pipelines. The spray frame 8 is facing the top of the pressure roller 12, and the nozzle of the nozzle 11 on the side wall of the bottom frame 5 is aligned with the inner wall of the baffle plate 6, and the water tank 4 is connected to the spray frame 8 facing the pressure roller throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com