Novel cutting-off device for cutting off pouring gate

A cutting device, pouring gate technology, applied in sawing machine equipment, metal sawing equipment, maintenance and safety accessories, etc., can solve problems such as inability to use the cutting machine, no protection against debris, and dirty worktables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

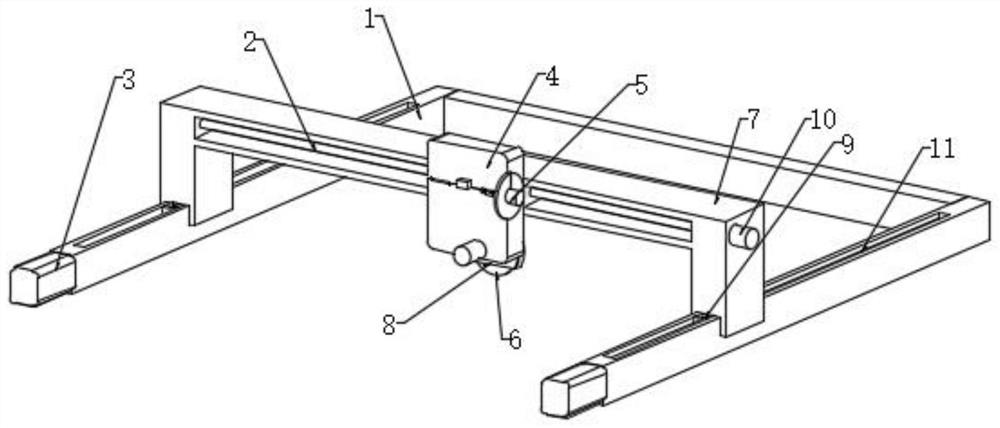

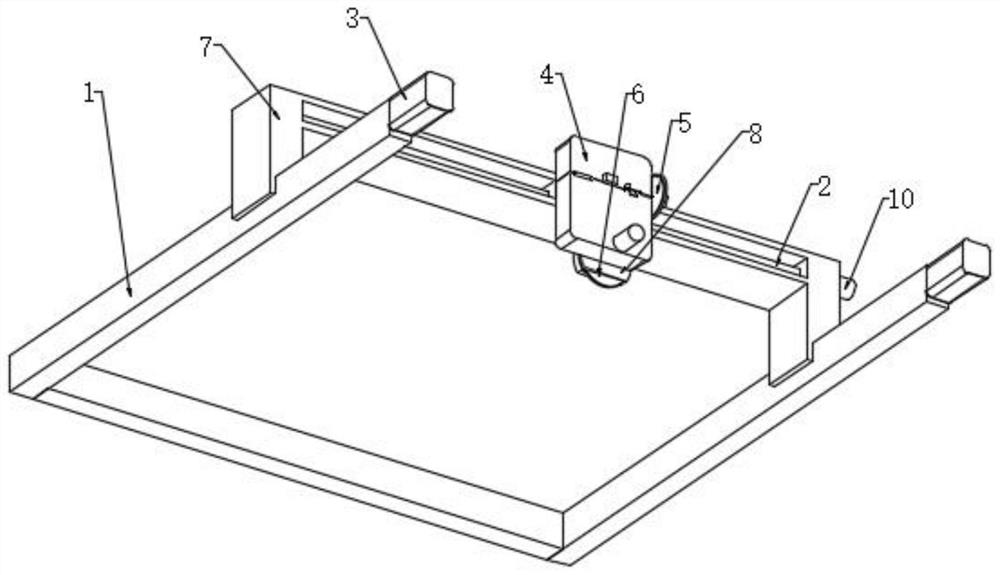

[0029] Such as Figure 1-7 As shown, a new type of cutting device for cutting the pouring mouth includes the first fixed frame 1, the cutting machine 6 and the second screw mandrel 11. In order to prevent the cutting machine 6 from interfering with the direction of travel, the existing cutting device cannot be used. Some cutting machines are used for cutting, which has low applicability and can only correspond to simple product shapes. A second fixing frame 7 is arranged between the first fixing frames 1, and a first screw rod 2 is arranged inside the second fixing frame 7. Through the cooperation of the first screw mandrel 2 and the second screw mandrel 11, before use, the two first fixing frames 1 are installed at the pouring mouth, and the first driving motor 3 can drive the first fixing frame 1 in the first fixing frame 1 at this time. The second screw mandrel 11 rotates, so that the second fixed mount 7 moves along the second screw mandrel 11, and the stand 4 is driven by...

Embodiment 2

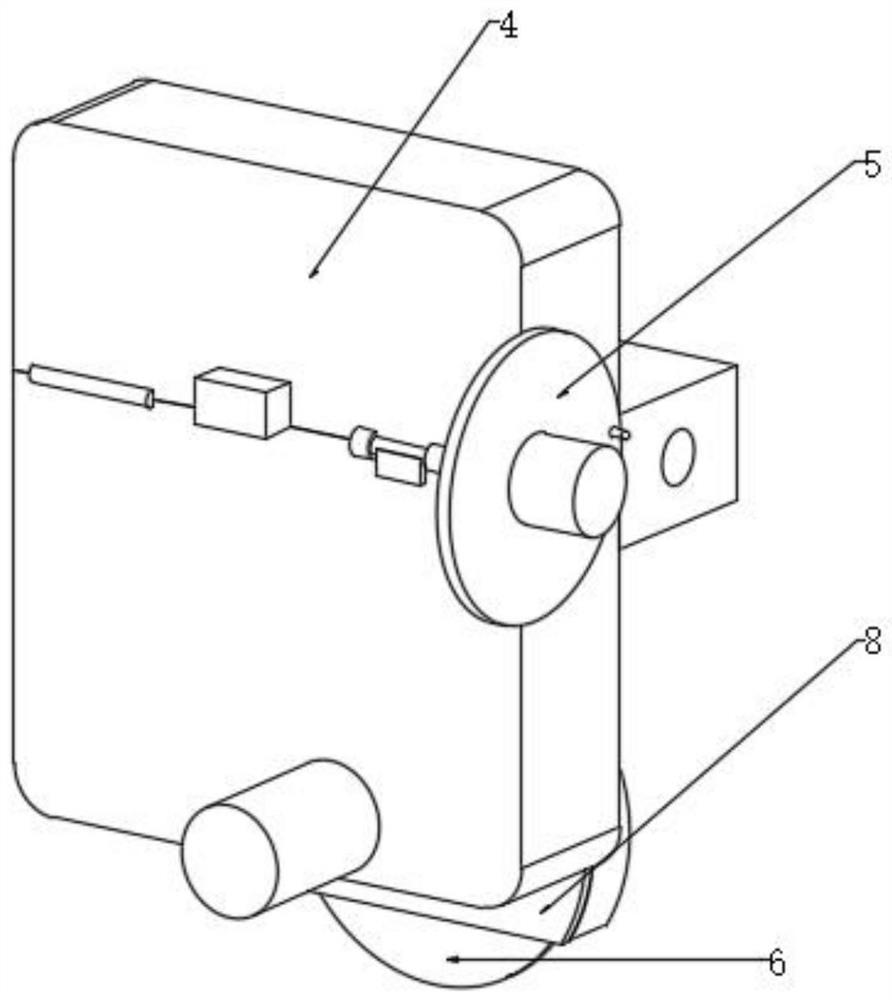

[0031] Such as image 3 and 4As shown, a new type of cutting device for cutting the pouring gate. In order to cut pouring gates with different orientations, a limit block 504 is arranged on the stand 4, and the angle between the limit block 504 and the first fixing plate 506 is 90°. °, the rotating disk 501 is provided with a rotating groove 503, and the rotating groove 503 is provided with two fixing holes and fixing pins, and the rotating motor 507 is located at the intersection of the stand 4 and the first fixing plate 506, cutting horizontally and vertically When the pouring port of the rotating disk 501 is pulled out from the fixing hole, the rotating shaft 502 is driven to rotate 90° by the flow stabilizer. Since the first fixing plate 506 rotates 90° around the rotating shaft 502, the fixing pin penetrates The fixing hole is fixed with the first fixing plate 506, the rotating disk 501 is welded on the side wall of the stand 4, the rotating shaft 502 is connected with t...

Embodiment 3

[0033] Such as Figure 5 As shown, a new type of cutting device for cutting the pouring port. In order to prevent the cutting debris from splashing out on the side of the blade when sawing the casting, it is easy to cause the workbench to be relatively dirty. The second fixing plate 802 One side is provided with a cover plate 801, the cover plate 801 is fixed to the second fixed plate 802 by bolts, and a first reserved hole 803 is arranged between the cover plates 801, and a first reserved hole 803 is provided on one side of the second fixed plate 802. Reserved groove 804, telescopic plate 807 is positioned in the first reserved groove 804, and telescopic plate 807 is provided with guide strip 806, and the inside of first reserved groove 804 is provided with the mating groove that cooperates with guide strip 806, in cutting When cutting, the telescopic plate 807 is slidably connected to the inside of the first reserved groove 804, and the guide bar 806 is slidably connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com