Soft substrate coating grinding device and formula and preparation method thereof

A technology for coating abrasive tools and coating abrasive tools on soft substrates, which is applied in abrasives, manufacturing tools, metal processing equipment, etc. problem, to achieve the effect of excellent chip removal performance, soft structure and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

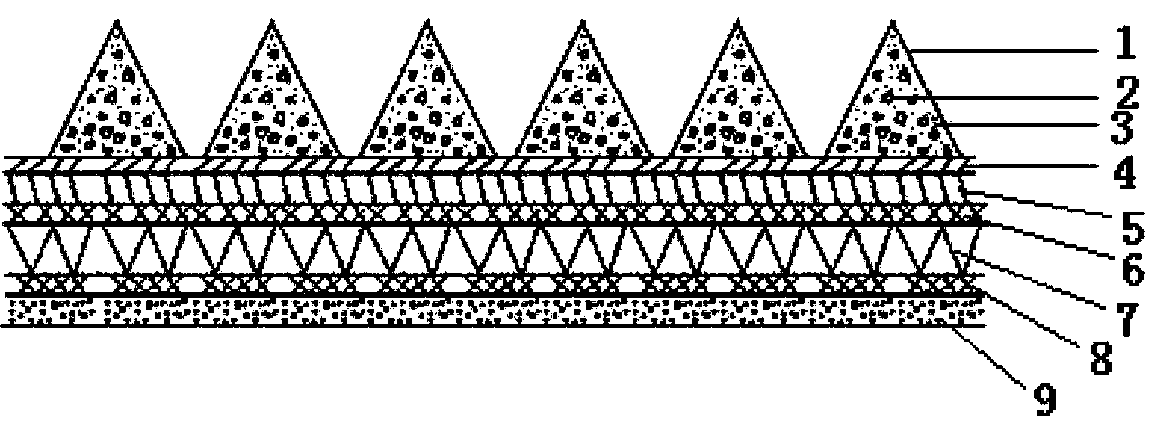

[0030] refer to figure 1 , a soft substrate coated abrasive tool, comprising a primer layer 4, the upper end of the primer layer 4 is equidistantly connected with abrasive blocks 1, and the inner cavity of each abrasive block 1 is bonded with an adhesive 3 Abrasive protrusions 2, the lower end of the primer layer 4 is connected with a TPU soft film substrate 5, and the end of the TPU soft film substrate 5 away from the primer layer 4 is bonded with a sponge layer through the first hot melt adhesive layer 6 7. The end of the sponge layer 7 away from the first hot-melt adhesive layer 6 is bonded with Velcro 9 through the second hot-melt adhesive layer 8 .

[0031] The present invention also provides a formula for a soft substrate-coated abrasive tool. The soft substrate-coated abrasive tool includes an abrasive block 1, and the proportion of the abrasive block 1 according to weight is as follows:

[0032] Light curing adhesive 30 wt%

[0033] Thinner 20 wt%

[0034] Photoinit...

Embodiment 2

[0044] refer to figure 1 , a soft substrate coated abrasive tool, comprising a primer layer 4, the upper end of the primer layer 4 is equidistantly connected with abrasive blocks 1, and the inner cavity of each abrasive block 1 is bonded with an adhesive 3 Abrasive protrusions 2, the lower end of the primer layer 4 is connected with a TPU soft film substrate 5, and the end of the TPU soft film substrate 5 away from the primer layer 4 is bonded with a sponge layer through the first hot melt adhesive layer 6 7. The end of the sponge layer 7 away from the first hot-melt adhesive layer 6 is bonded with Velcro 9 through the second hot-melt adhesive layer 8 .

[0045] The present invention also provides a formula for a soft substrate-coated abrasive tool. The soft substrate-coated abrasive tool includes an abrasive block 1, and the proportion of the abrasive block 1 according to weight is as follows:

[0046] Light curing adhesive 46 wt%

[0047] Thinner 20 wt%

[0048] Photoinit...

Embodiment 3

[0058] refer to figure 1, a soft substrate coated abrasive tool, comprising a primer layer 4, the upper end of the primer layer 4 is equidistantly connected with abrasive blocks 1, and the inner cavity of each abrasive block 1 is bonded with an adhesive 3 Abrasive protrusions 2, the lower end of the primer layer 4 is connected with a TPU soft film substrate 5, and the end of the TPU soft film substrate 5 away from the primer layer 4 is bonded with a sponge layer through the first hot melt adhesive layer 6 7. The end of the sponge layer 7 away from the first hot-melt adhesive layer 6 is bonded with Velcro 9 through the second hot-melt adhesive layer 8 .

[0059] The present invention also provides a formula for a soft substrate-coated abrasive tool. The soft substrate-coated abrasive tool includes an abrasive block 1, and the proportion of the abrasive block 1 according to weight is as follows:

[0060] Light curing adhesive 35 wt%

[0061] Thinner 10 wt%

[0062] Photoiniti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com