Waste paper collecting device of paper making splitting machine

A collection device and slitting machine technology, applied in the field of papermaking, to achieve the effects of convenient operation, elimination of flying everywhere, improvement of work efficiency and degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

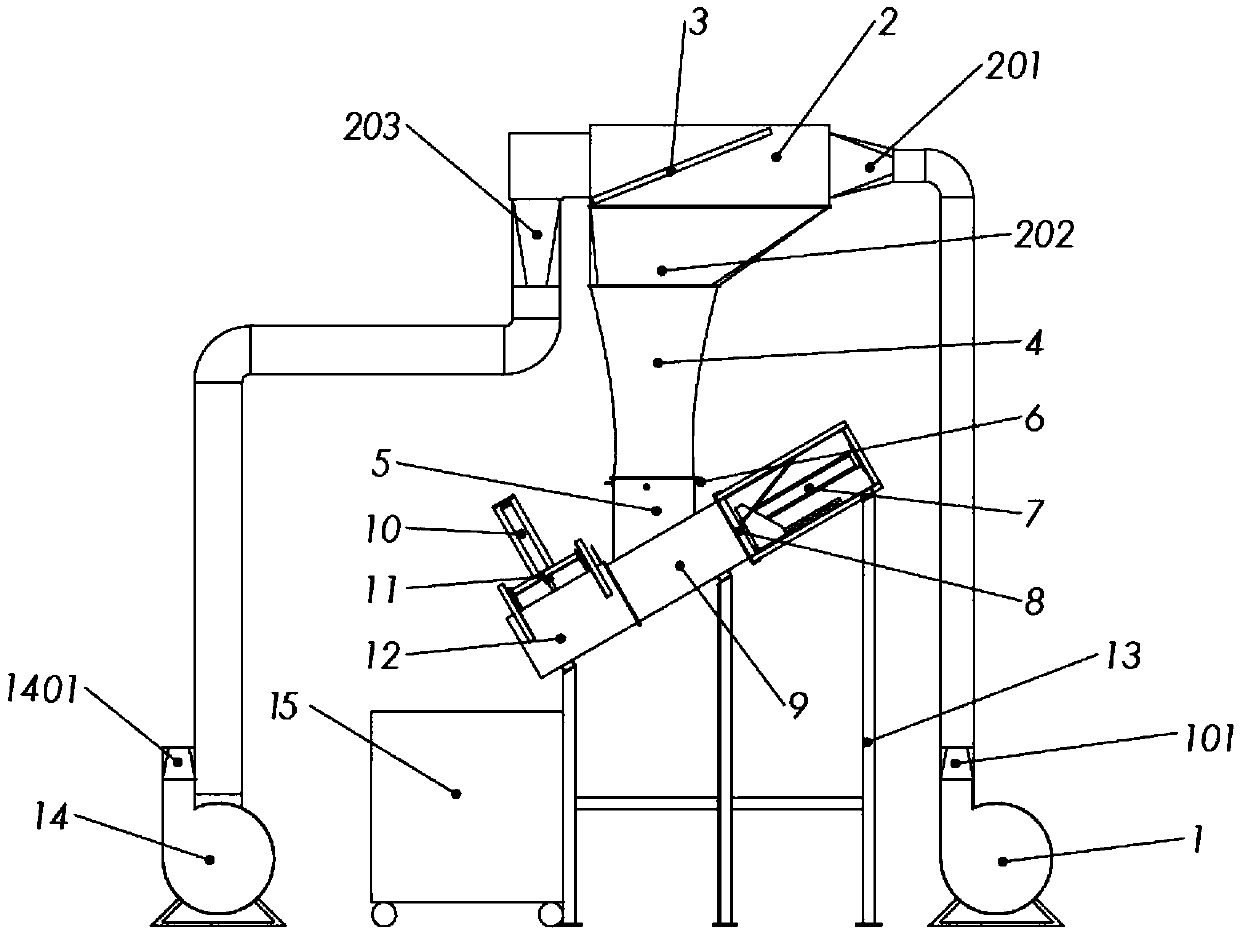

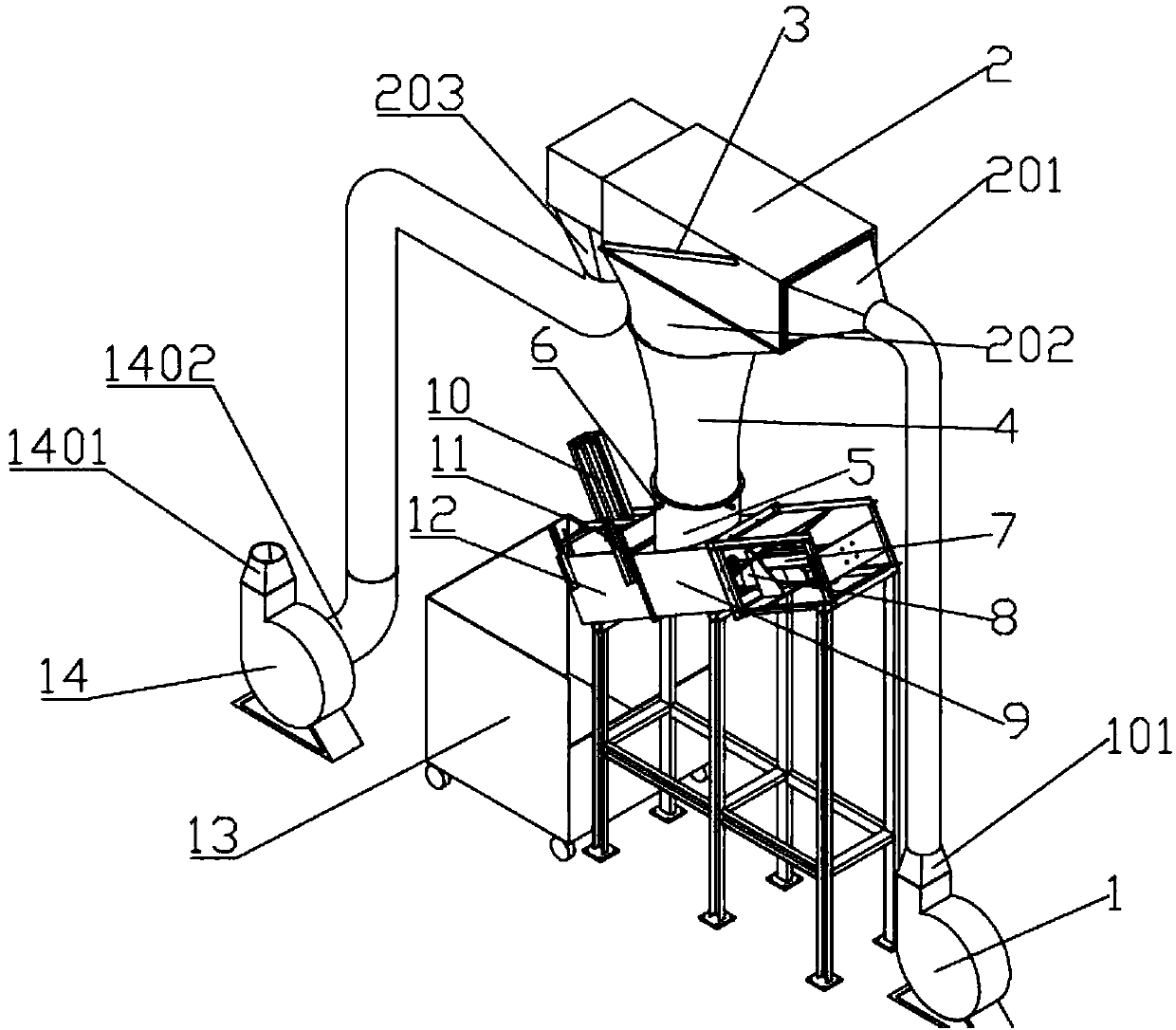

[0027] A waste paper collecting device of a paper cutting machine, comprising: a paper dust separator 2, a waste paper compressor and a frame 13,

[0028] Among them, the inside of the paper dust separator 2 is divided into two cavities by the replaceable fine-mesh screen 3, one side of the cavity is provided with a waste paper inlet 201 and a paper edge outlet 202, and the other side of the cavity is provided with a paper dust outlet 203, the waste paper inlet 201 is connected to the air pump outlet 101 through a pipeline, the paper dust outlet 203 is connected to the pressure relief fan inlet 1402 through a pipeline, and the paper edge outlet 202 is connected to the wear-resistant and non-stick oil gauze 4, which is wear-resistant The bottom 4 of the non-stick oil gauze is a waste paper compressor,

[0029] The waste paper compressor includes: a water spray section 5, an accumulation bin 9 and a compression bin 12, the water spray section 5 is connected with the wear-resista...

Embodiment 2

[0040] A waste paper collecting device of a paper cutting machine, comprising: a paper dust separator 2, a waste paper compressor and a frame 13,

[0041] Among them, the inside of the paper dust separator 2 is divided into two cavities by the replaceable fine-mesh screen 3, one side of the cavity is provided with a waste paper inlet 201 and a paper edge outlet 202, and the other side of the cavity is provided with a paper dust outlet 203, the waste paper inlet 201 is connected to the air pump outlet 101 through a pipeline, the paper dust outlet 203 is connected to the pressure relief fan inlet 1402 through a pipeline, and the paper edge outlet 202 is connected to the wear-resistant and non-stick oil gauze 4, which is wear-resistant The bottom 4 of the non-stick oil gauze is a waste paper compressor,

[0042] The waste paper compressor includes: a water spray section 5, an accumulation bin 9 and a compression bin 12, the water spray section 5 is connected with the wear-resista...

Embodiment 3

[0046] A waste paper collecting device of a paper cutting machine, comprising: a paper dust separator 2, a waste paper compressor and a frame 13,

[0047] Among them, the inside of the paper dust separator 2 is divided into two cavities by the replaceable fine-mesh screen 3, one side of the cavity is provided with a waste paper inlet 201 and a paper edge outlet 202, and the other side of the cavity is provided with a paper dust outlet 203, the waste paper inlet 201 is connected to the air pump outlet 101 through a pipeline, the paper dust outlet 203 is connected to the pressure relief fan inlet 1402 through a pipeline, and the paper edge outlet 202 is connected to the wear-resistant and non-stick oil gauze 4, which is wear-resistant The bottom 4 of the non-stick oil gauze is a waste paper compressor,

[0048] The waste paper compressor includes: a water spray section 5, an accumulation bin 9 and a compression bin 12, the water spray section 5 is connected with the wear-resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com